Adjustable small-radius bridge girder erection machine and bridge girder erection method

A small-radius, adjustable technology, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., to achieve the effects of easy promotion, shortened construction period, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

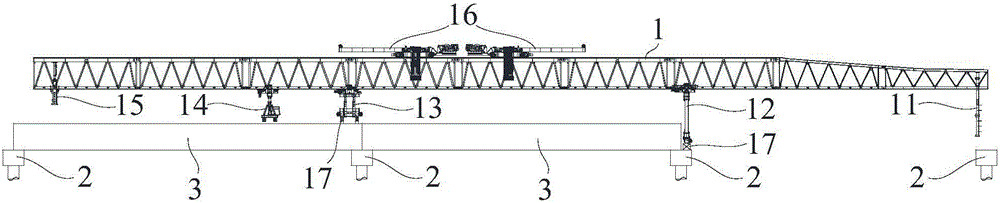

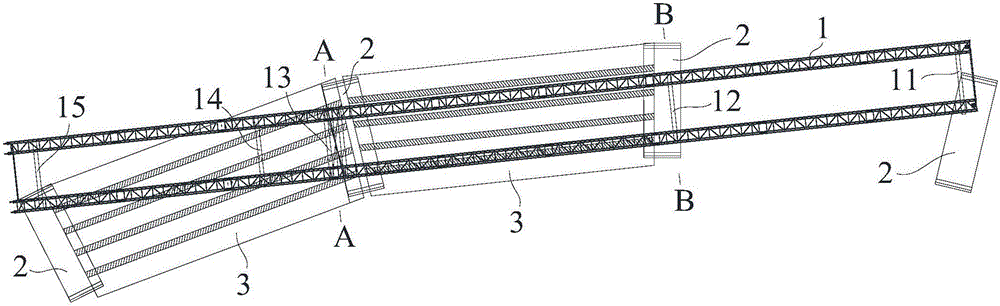

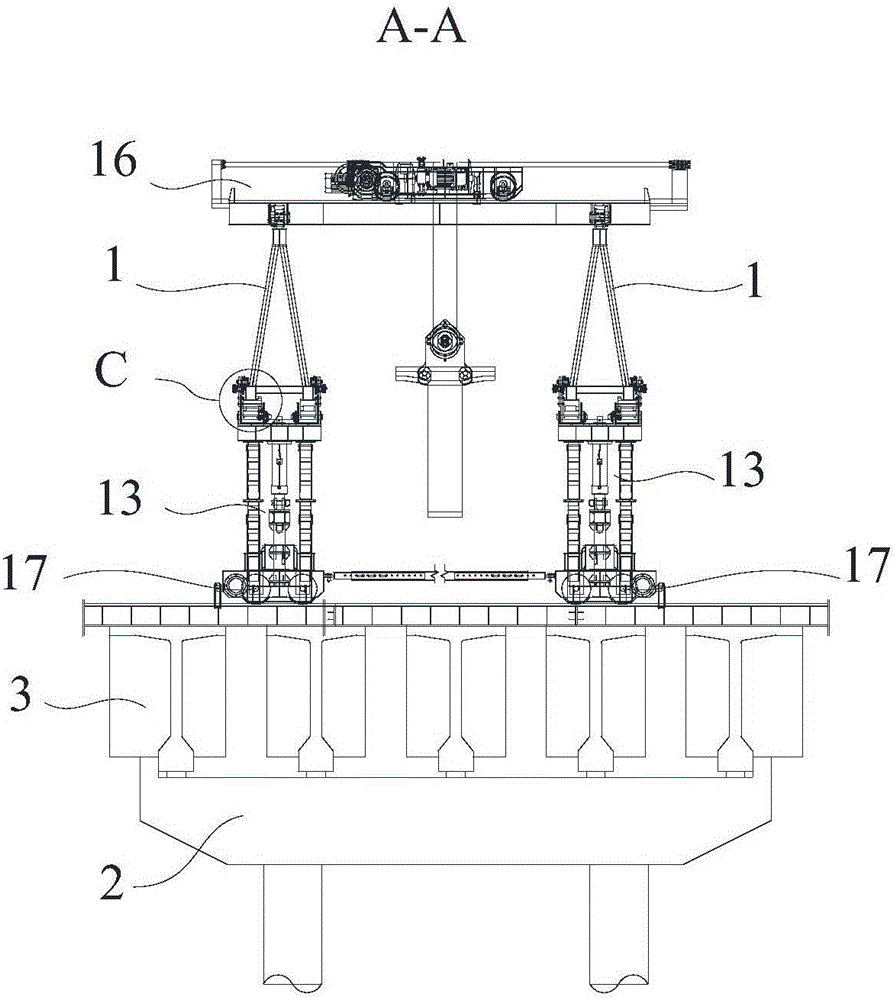

[0041] Such as Figure 1-6 As shown, an adjustable small-radius bridge erecting machine according to the present invention includes two main girders 1 arranged in parallel, and a hoisting mechanism 16 arranged between the two main girders 1 .

[0042]The bottom of each main girder 1 is also connected with support leg one 12, support leg two 13, support leg three 11 and support leg four 15, and all the bottoms of support leg one 12 and support leg two 13 are provided with several transverse The moving mechanism 17 and the top are equipped with several rollers 18, and the bottom of each said traversing mechanism 17 contacts the pier 2 or the box girder 3 and can move laterally relative to the pier 2 or the box girder 3, and each of the said rollers 18 has two Each end is provided with a limiting plate 181, and the distance between all the two opposing limiting plates 181 is adjustable. Each main beam 1 is slidably connected to all the rollers 18 on the corresponding side, and is...

Embodiment 2

[0048] Such as Figure 1-6 As shown, the bridging method of an adjustable small-radius bridge-erecting machine according to the present invention includes an adjustable small-radius bridge-erecting machine as described in Embodiment 1, and its bridging method includes the following steps:

[0049] A, normal beam erection, at this moment, the distance between all the two relative limiting plates 181 is the smallest, and the first leg 12 and the second leg 13 in the horizontal plane are all perpendicular to the main beam 1;

[0050] B. When the girder goes to the place where the small-radius flat curve bridge is erected, the distance between all the two relative limiting plates 181 is increased, and the third leg 11 and the fourth leg 15 are overhead, That is, the third leg 11 and the fourth leg 15 are raised until they leave the corresponding pier 2 or box girder 3;

[0051] C. Drive the lateral movement mechanism 17 on the second leg 13 to move laterally, so that the main bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com