Induction hardening fixture for inner cavity of three-pillar groove shell of flange plate

A technology of induction hardening and three-column grooved shell, which is applied in the field of clamping fixtures, can solve the problems of inconvenient clamping, large clamping range of product differences, etc., to ensure effective clamping, expand the clamping range, and eliminate gaps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

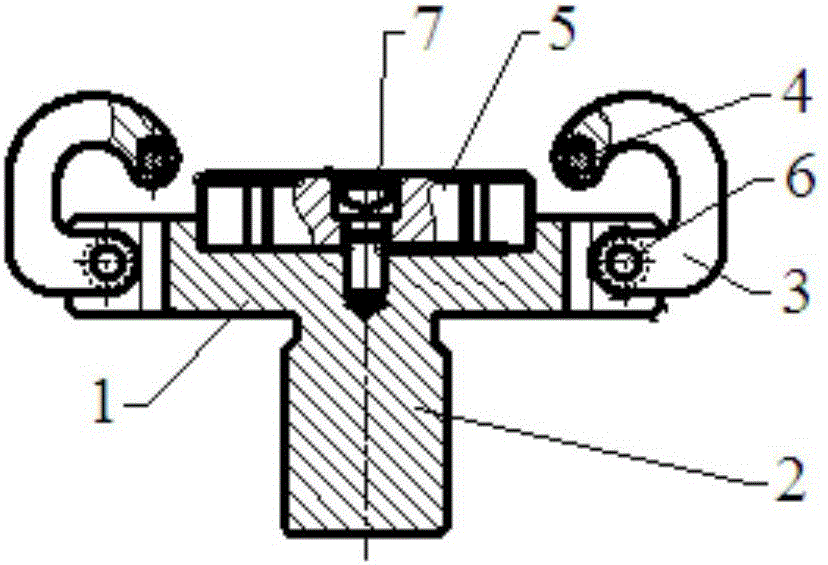

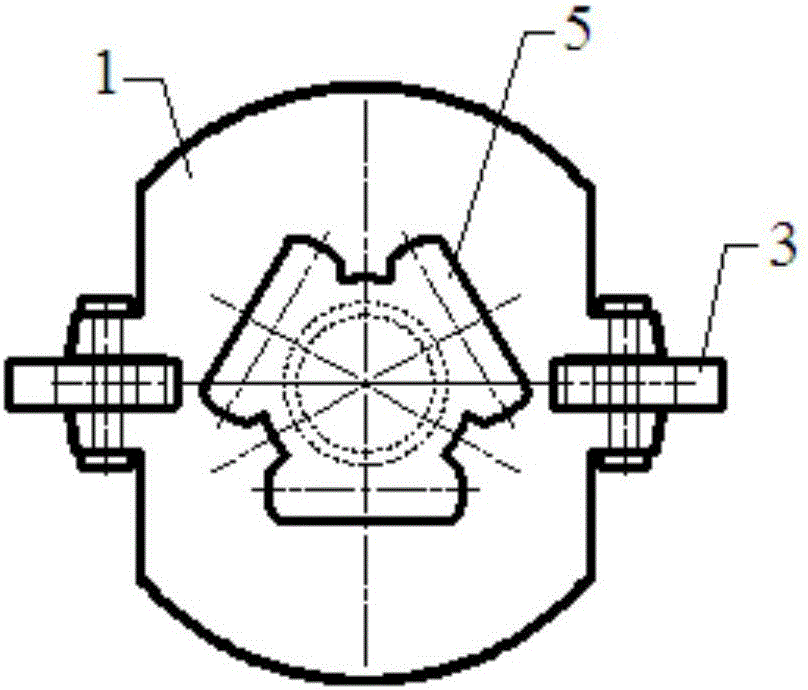

[0019] see figure 1 , 2 , a flange plate three-column groove shell cavity induction hardening fixture, including a base 1, the bottom of the base 1 has an integrally connected connecting handle 2, the two sides of the base 1 are respectively rotated and installed with locking hooks 3, The front ends of the locking hooks 3 are respectively connected with rubber elastic bodies 4, and a positioning block 5 is fixedly installed on the base 1, and the shape of the positioning block 5 is consistent with the inner cavity shape of the three-column groove shell of the flange.

[0020] In the present invention, the connecting handle 2 can be connected with the hydraulic chuck of the induction hardening machine tool.

[0021] The locking hooks 3 are respectively rotatably mounted on both sides of the base 1 through the rotating shaft pins 6 .

[0022] The positioning block 5 is fixed on the base 1 by screws 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com