A kind of preparation method of cyclohexanone oxime

A technology of cyclohexanone oxime and cyclohexanone, applied in the field of preparation of cyclohexanone oxime, can solve the problem of low cyclohexanone conversion rate and cyclohexanone oxime selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

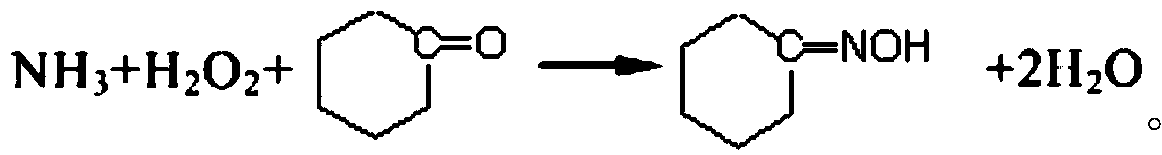

[0013] The preparation method of cyclohexanone oxime provided by the present invention comprises that in the presence of an oximation catalyst, cyclohexanone, ammonia and hydrogen peroxide are subjected to an ammoximation reaction in a solvent, wherein the solvent contains a small amount of an inert organic solvent of aqueous solution.

[0014] In the present invention, the aqueous solution containing a small amount of inert organic solvent means that the content of a small amount of inert organic solvent in the aqueous solution is not higher than 30% by weight based on the total weight of the aqueous solution.

[0015] According to the preparation method of cyclohexanone oxime provided by the present invention, the addition of an inert organic solvent in the ammoximation reaction system can improve the mass transfer and heterogeneous phase separation effect of the reaction system, thereby obtaining a higher reaction yield and subsequent suspension liquid separation efficiency...

specific Embodiment approach

[0027] According to a specific embodiment of the present invention, the preparation method of cyclohexanone oxime comprises sending cyclohexanone, ammonia, hydrogen peroxide, an inert organic solvent, additionally added water and an oximation catalyst into an ammoximation reactor for Ammoximation reaction, and the reaction product is extracted with the above-mentioned inert organic solvent, and then sent to a cyclone separator and a decanter for separation to obtain the oil phase containing cyclohexanone oxime and the water containing oximation catalyst and water phase, and the aqueous phase containing the oximation catalyst and water is returned to the ammoximation reactor to continue the ammoximation reaction.

[0028] The present invention will be described in detail below by way of examples.

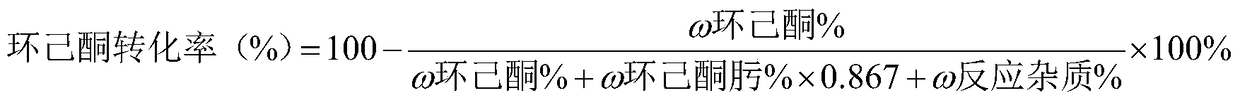

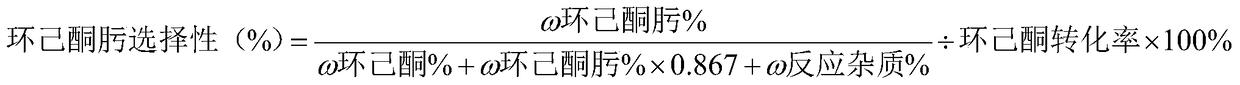

[0029] In the following examples and comparative examples:

[0030] The oximation catalyst is a titanium-silicon molecular sieve (TS-1) catalyst, which is according to the document ...

Embodiment 1

[0036] This example is used to illustrate the preparation method of cyclohexanone oxime provided by the present invention.

[0037] The volume ratio of toluene to cyclohexanone in the mixed solution of cyclohexanone and toluene used in this embodiment is 5:100. First, add 100.00g of water and 3.00g of oximation catalyst (TS-1) into the glass reactor with stirring, then pass the mixture of cyclohexanone and toluene, ammonia and hydrogen peroxide (concentration is 27.5% by weight) through advection pump Continuously sent into the glass reactor, wherein, the flow rate of the above-mentioned several kinds of materials is 10.50g / h, 1.99g / h, 14.89g / h successively. The temperature of the reaction system is controlled at 86-90° C. and the pressure is controlled at 0.3-0.4 MPa. After the materials stay in the glass reactor for 70 minutes, a reaction product containing cyclohexanone oxime and an oximation catalyst (TS-1) is obtained. Then the obtained reaction product containing cycloh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com