Combination type garbage can

A trash can and combined technology, applied in the field of trash cans, can solve problems affecting the living environment, unfavorable management, easy aging, etc., and achieve the effect of a simplified overall structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

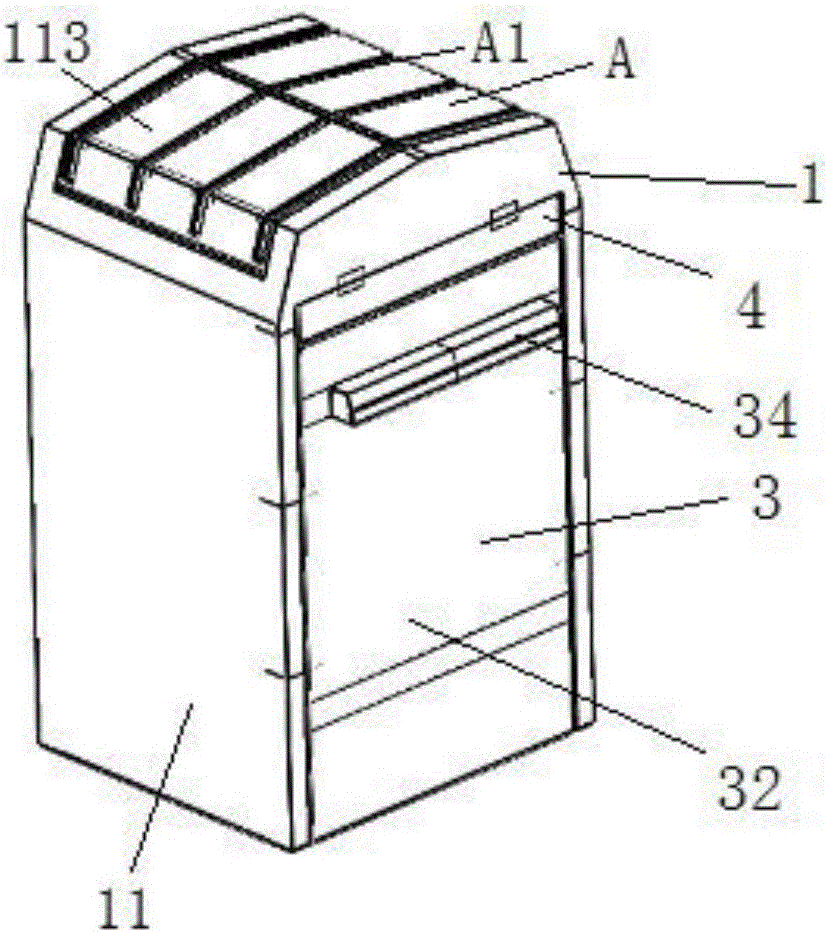

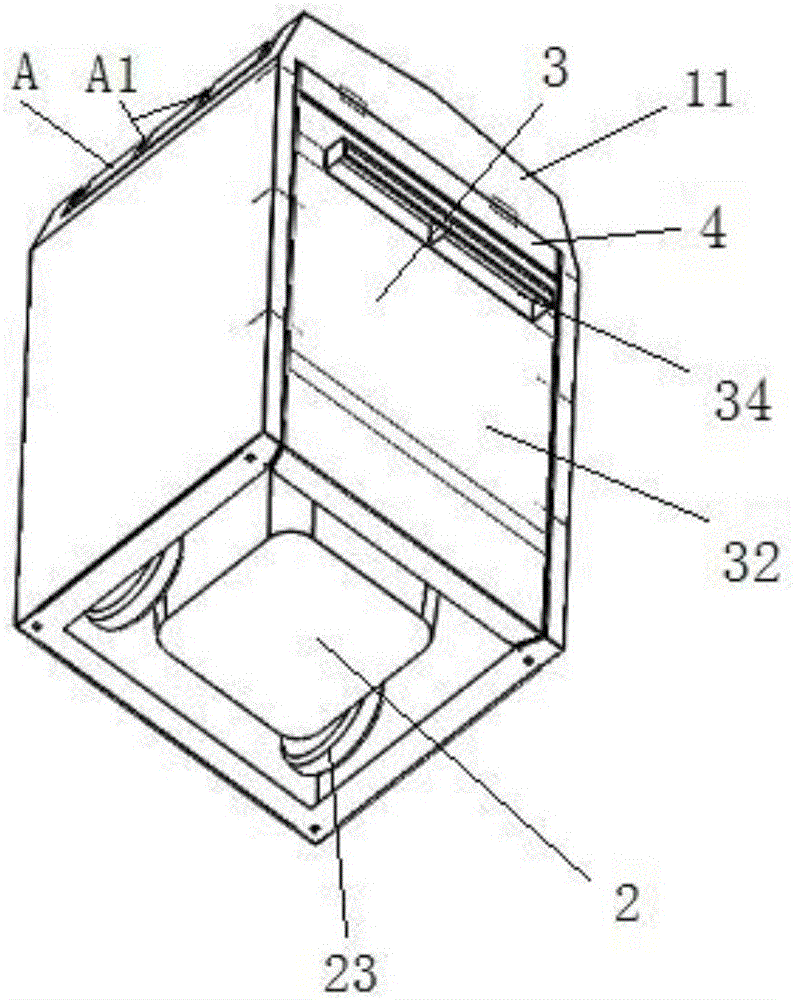

[0049] see Figure 1-Figure 8 , a combined trash can, comprising a trash can shell 1, a trash can inner barrel 2 and a cover plate 3 movable and independently arranged inside the trash can shell 1, the trash can shell 1, the trash can inner barrel 2 and the cover plate 3. The three are set independently of each other (here, the cover plate and the inner barrel of the trash can can also be used as an integrated structure according to actual needs, and its operation process is similar to the opening and closing operation of the drawer).

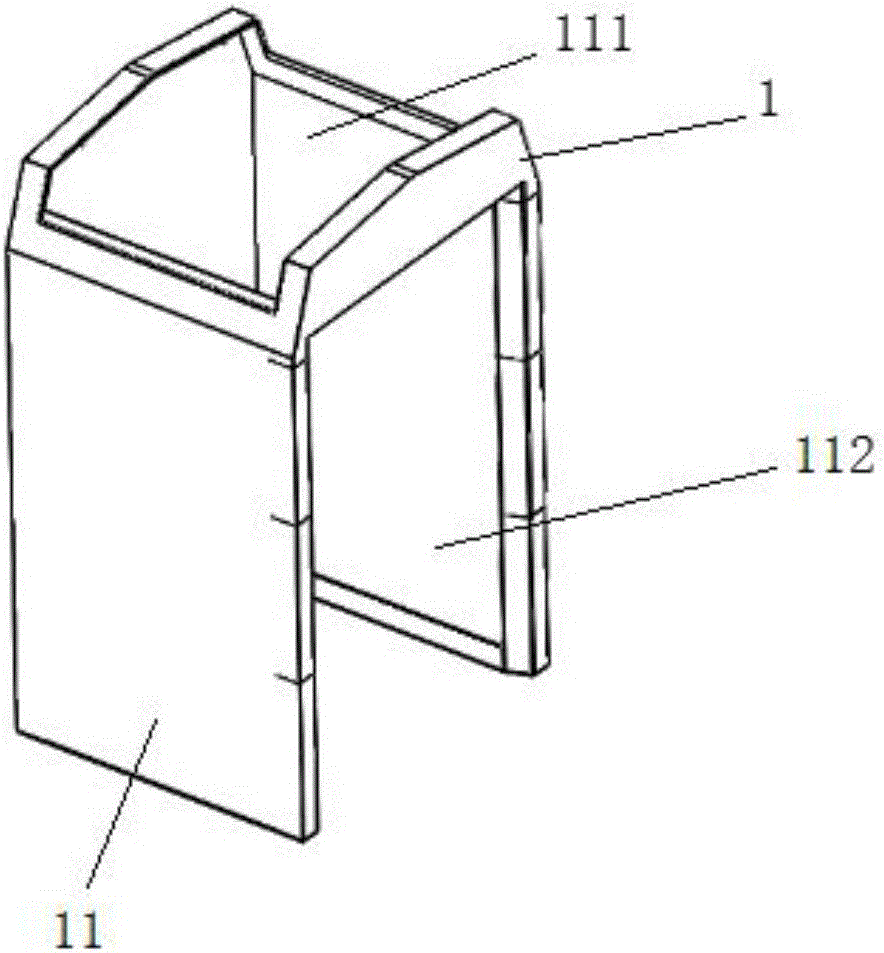

[0050] The trash can shell 1 includes a shell body 11, and the shell body 11 is provided with a garbage input port 111 for putting in garbage and a first opening 112 for the trash can inner barrel 2 to enter and exit the trash can shell 1, so The first opening 112 is also provided with a flip cover 4 (see figure 1 , figure 2 as well as image 3 ), the upper end of the flip cover 4 is hinged on the upper end of the first opening 112, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com