Intelligent mortar stirrer

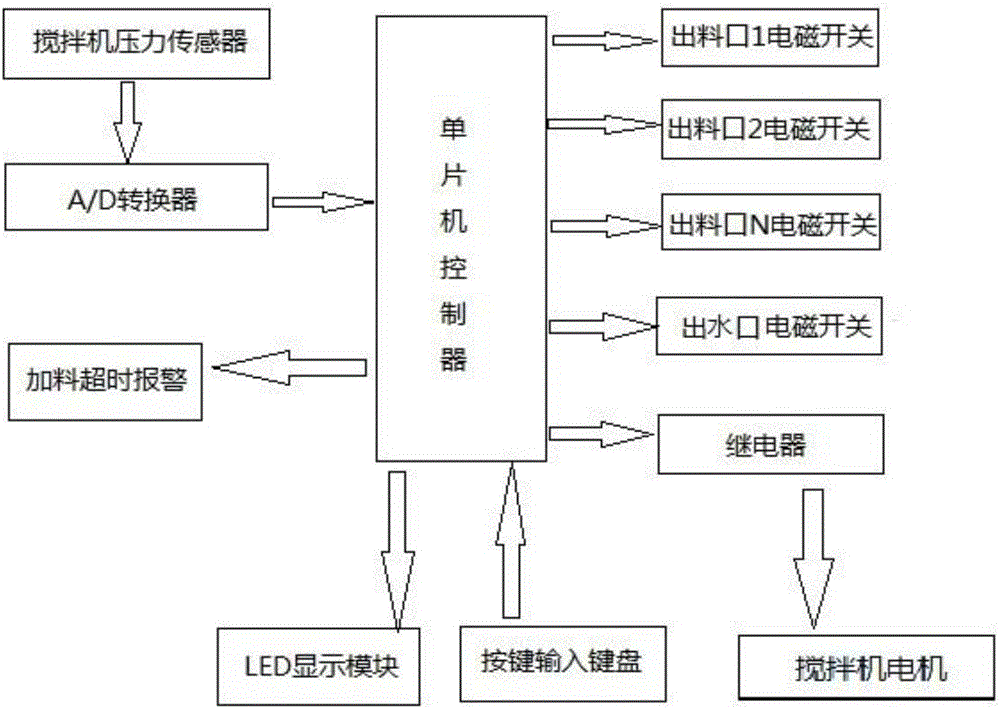

A mortar mixing and mixer technology, which is used in mixing plants, cement mixing devices, batching and batching instruments, etc., can solve the problems of low sensory reliability, low production efficiency, low input and output, etc., to improve construction efficiency and investment. Output ratio, solving manual operation errors, shortening the effect of mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

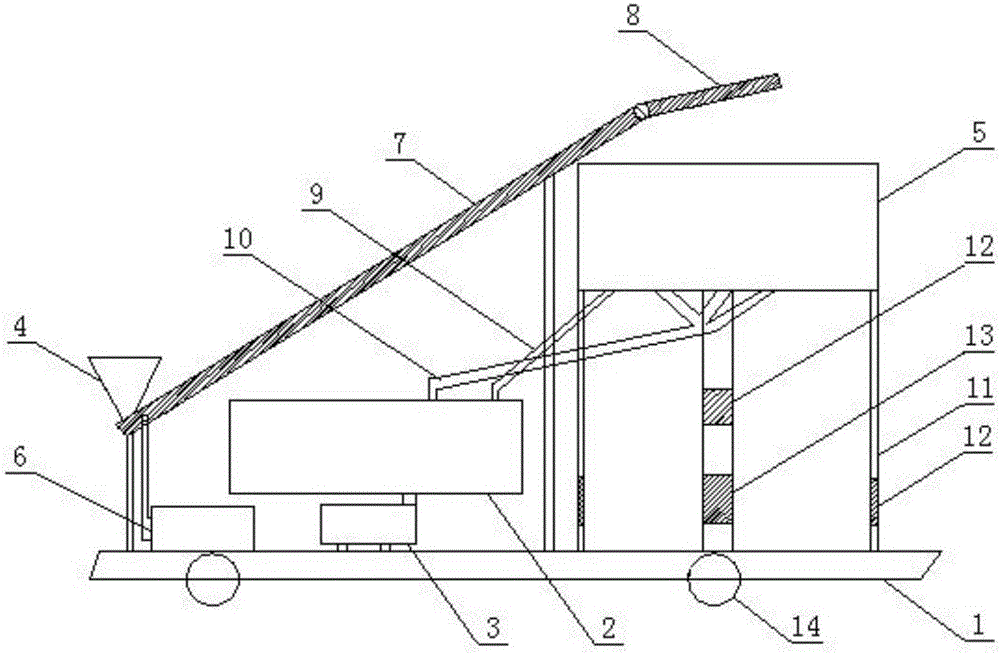

[0019] as attached figure 1 with 2 As shown, an intelligent mortar mixer includes a base 1. In this embodiment, the base 1 is welded with square steel, and is provided with wheels 14 to realize the moving function; the base 1 is provided with a mortar mixing tank 2, and The mortar mixing tank 2 is connected to the mixer motor 3 .

[0020] In the present invention, the base 1 is also provided with a material storage separation groove 5 and a material feeding port 4 through a bracket, and the material feeding port 4 transports raw materials to the material storage separation groove 5 through a motor 6 and a conveying device 7, Wherein, the end of the conveying device 7 is provided with a feeding chute 8 with adjustable direction and angle, which can accurately transport raw materials to different partitions of the storage separation tank 5; the storage separation tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com