Machining progressive die used for increasing height of fins

A progressive die and height technology, which is applied in the field of fin processing, can solve the problems of the positioning hole height remaining unchanged or increasing, and the fin material becoming thinner, so as to improve heat dissipation efficiency, increase the force bearing area, and facilitate adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

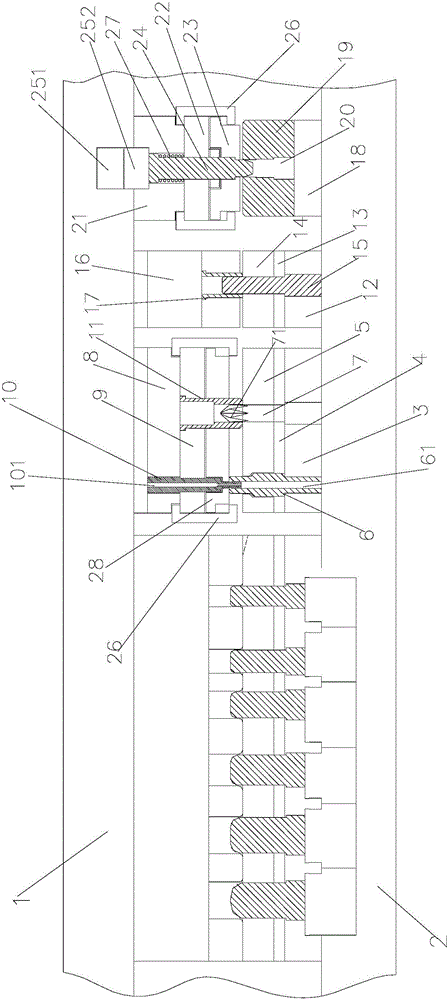

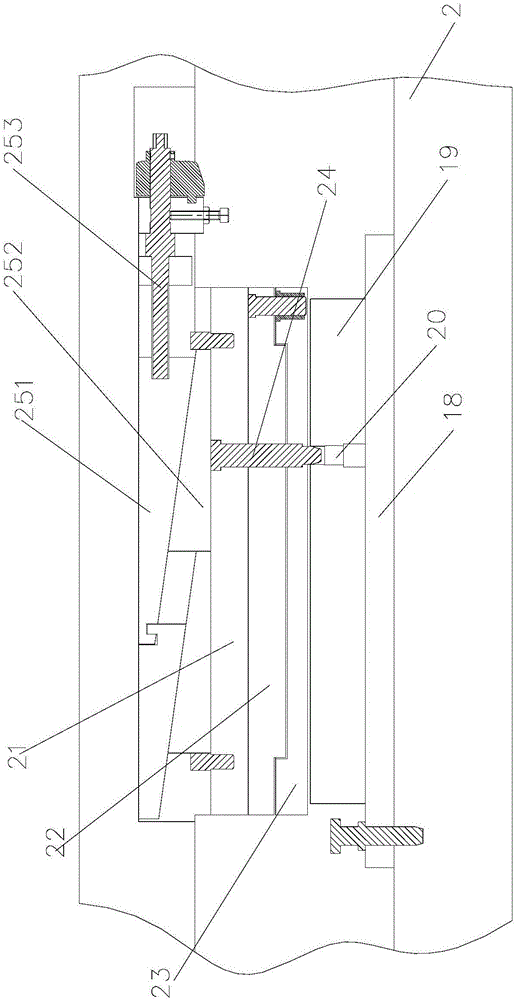

[0024] Examples such as Figures 1 to 5 As shown, a processing progressive die used to increase the height of the fins includes an upper template 1 and a lower template 2, and an extension station is arranged between the upper template 1 and the lower template 2. After the extension station, there are sequentially arranged Stations for punching, tearing, straightening and flanging.

[0025] The stretching station forms convex hulls on the fins through the continuous action of a set of stretching punches and stretching dies. This station is identical with existing design, does not describe in detail here.

[0026] The punching station punches a process hole on the end surface of the convex hull punched out by the extension station, so as to facilitate the cutting of the convex hull end surface by the next tearing station.

[0027] The tearing station cuts the end surface of the convex hull into several parts from the process hole to the surroundings;

[0028] The straighteni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com