In-situ electric heating desorption restoration technology and device for contaminated site

An electric heating and field technology, applied in the field of soil remediation, can solve the problems of easily damaged heating pipes, high energy consumption, and inability to effectively and stably control the heating temperature of polluted areas, so as to ensure the restoration effect, high degree of automation, and safety of energy saving and consumption reduction The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

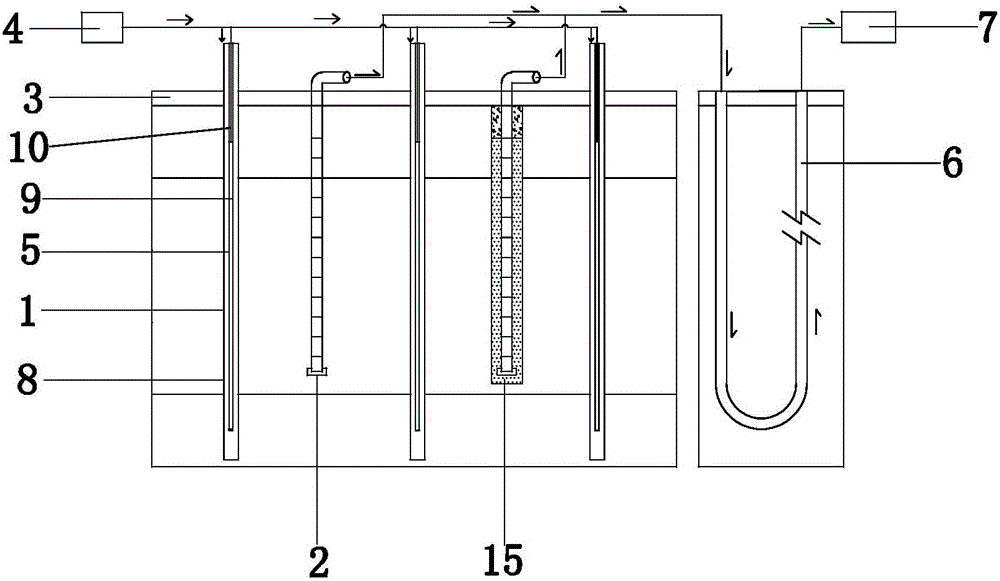

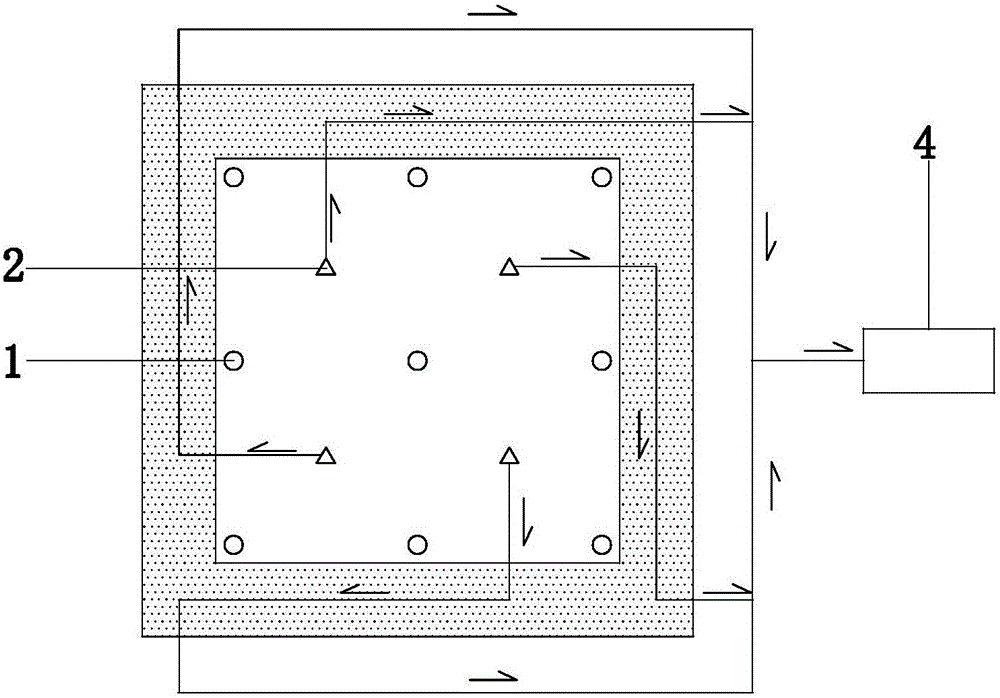

[0028] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment: see Figure 1-6 ,

[0029] The in-situ electric heating desorption repair technology for polluted sites includes the following steps:

[0030] a. Insert several heating wells 1 and extraction wells 2 into the polluted site, the insertion depth is 1-4 meters;

[0031] b. Lay a thermal insulation layer 3 on the surface of the polluted site, and the thermal insulation layer is made of lightweight concrete;

[0032] c. Treat the groundwater in the polluted site as precipitation, and lower the groundwater to a position 5 meters below the ground;

[0033] d. The power supply facility 4 is electrically connected to several heating wells 1 and extraction wells 2, the heating pipe 5 in the heating well 1 is used to heat the polluted site, and the vacuum pump in the extraction well is used to pump out the gaseous pollutants and pollution generated in the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com