Preparation method of SiOx-based lithium ion battery composite anode material

A negative electrode material, ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of cycle performance deterioration, loss of electrical contact, capacity attenuation, etc., to improve conductivity, suppress volume changes, and improve cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

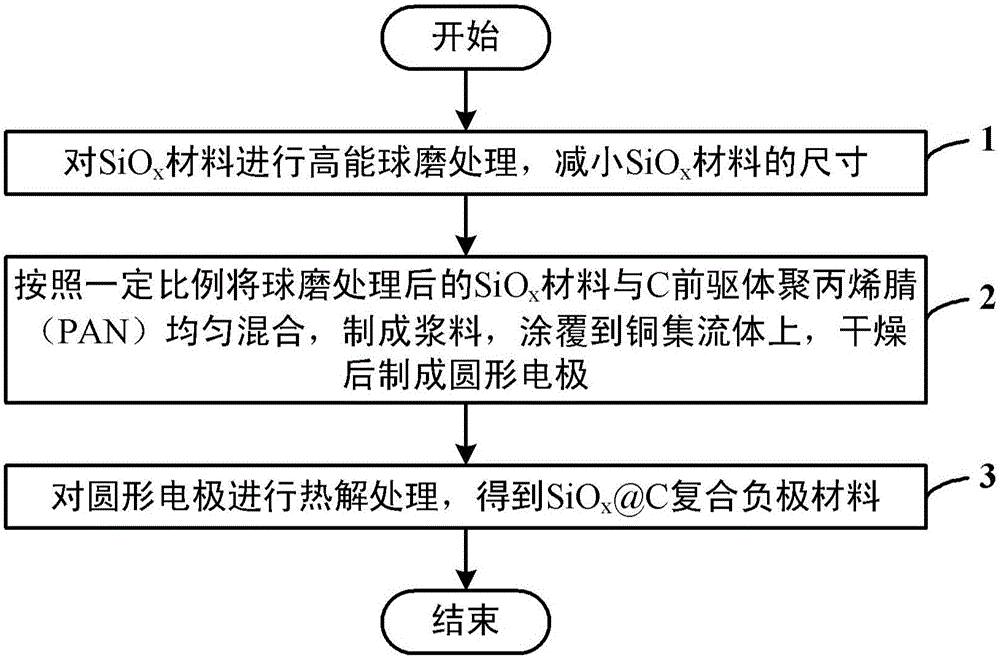

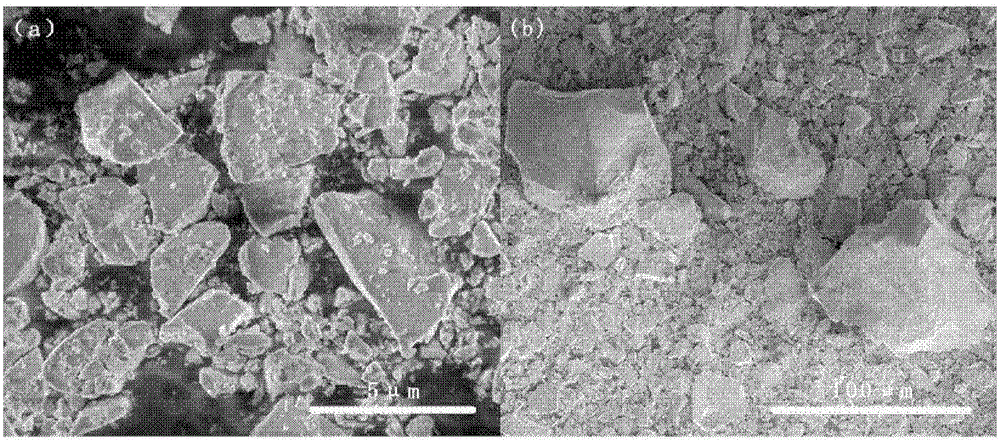

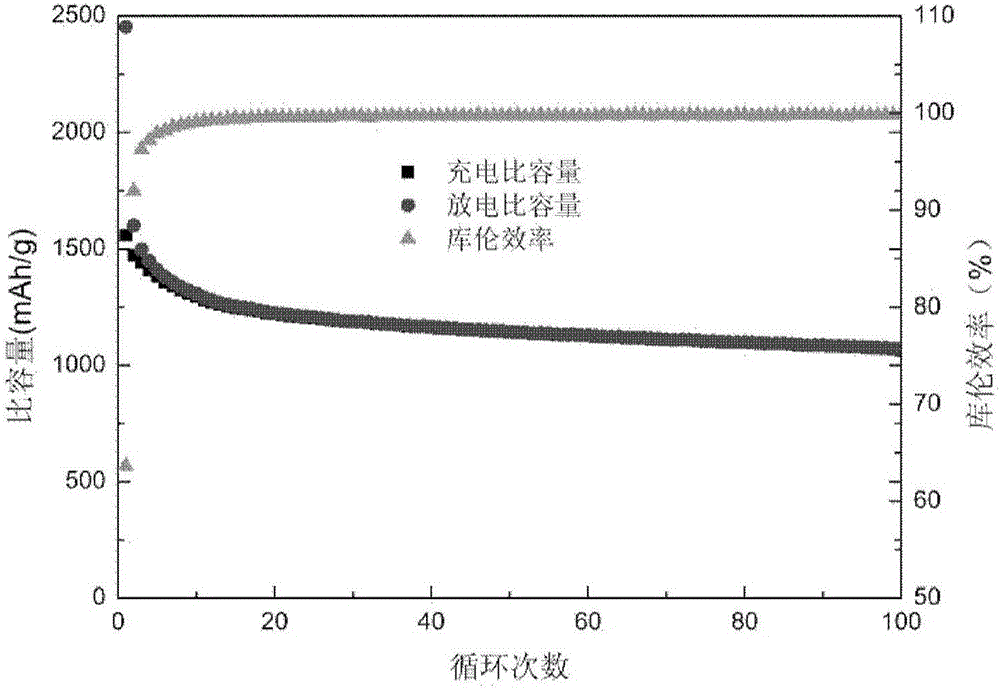

[0022] The present invention proposes a simple SiO x A method for preparing a composite negative electrode material for a lithium-ion battery, using high-energy ball milling to make SiO x The size is effectively reduced, and by mixing with the C precursor polyacrylonitrile (PAN), a slurry is made, coated on a copper current collector, and dried to form a circular electrode, and subjected to pyrolysis treatment to obtain SiO x C composite anode material.

[0023] The SiO proposed by the present invention x Preparation method of composite negative electrode material for lithium-ion battery based on SiO x As the initial material, SiO was effectively reduced by a simple high-energy ball milling method combined with heat tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com