Automatic release force testing device

An automatic test device and peeling force technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of inconvenient operation, complex structure, high maintenance cost, etc., and achieve convenient detection test, accurate detection results and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

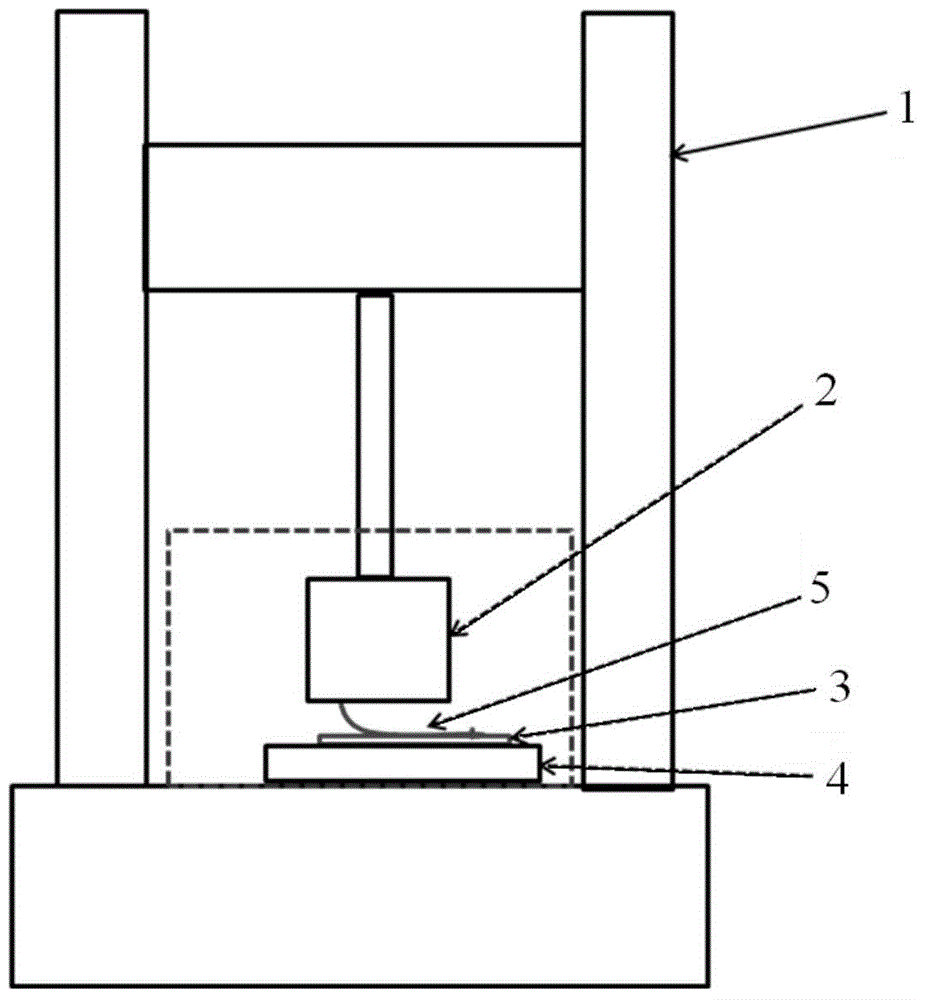

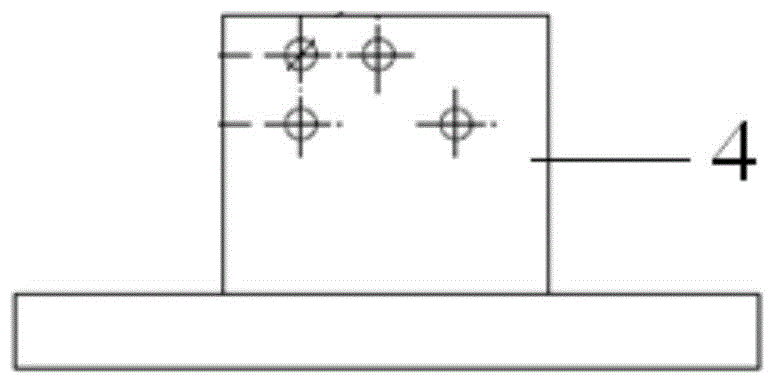

[0019] A peel force automatic test device, such as figure 1 As shown, the test device includes a row tension component 1 , a fixture 2 , a template 3 and a fixed test component 4 . Wherein, the tape 5 to be tested is placed on the template 3, and the other end of the tape 5 to be tested is bonded to the fixture 2. Specifically, the other end of the tape 5 to be tested is fixed in place by the fixture 2 and connected to the push-pull component 1. The push-pull component 1 adopted is an H-shaped structure, and the cross beam in the middle is movably connected to the frame on both sides, and can move up and down along the frame, thereby pulling up the adhesive tape 5 . The template 3 is placed on the fixed test assembly 4, and the structure of the fixed test assembly 4 is as follows: figure 2 As shown, it is a T-shaped structure, and there are two upward protrusions arranged on the bottom surface, which are arranged side by side for fixing the template 3 .

[0020] When the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com