Roller pin and roller diameter detector

A detector and roller technology, used in instruments, measuring devices, etc., can solve the problems of unsatisfactory detection of product accuracy, easy damage, and large errors, and achieve the effect of reducing human measurement errors and improving detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

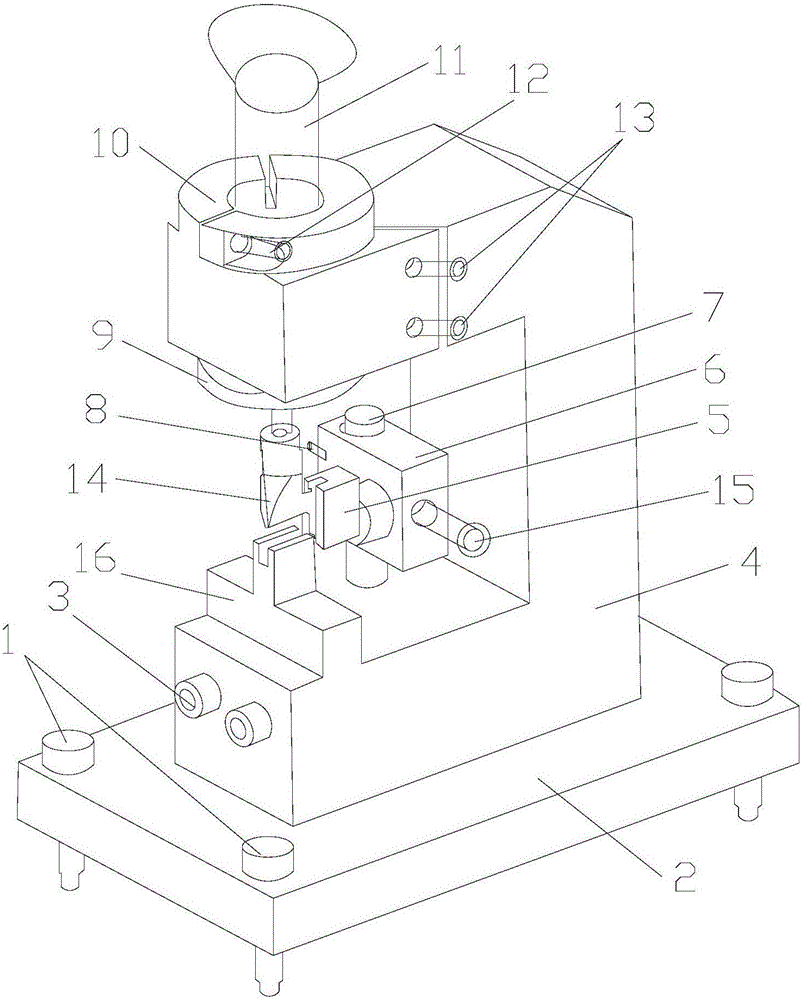

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention comprises base 2, measuring platform 4, instrument 11, and described measuring platform 4 is a concave structure, and is fixed on the base 2; The lifting cylindrical rod 7 is covered with a backing bracket 6, on which the backing bracket 6 is provided with a measuring backing 5; on the inner bottom surface of the measuring platform 4, a measured piece placement platform 16 is arranged, and the measured piece placement platform 16 is connected to the bottom surface of the measurement platform 4. The measuring backer 5 and the instrument measuring head 14 are on the same center line; the upper plane of the measuring platform 4 is equipped with a watch tube 10, and the watch tube fine-tuning nut 9 is arranged below the watch tube 10, and a watch tube 10 is placed inside the watch tube 10. The meter 11 and the meter probe 14 are fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com