Engine damping control device and method

A control device and control method technology, applied in the direction of vibration suppression adjustment, spring/shock absorber, mechanical equipment, etc., can solve the problems of passive component loss, inconvenience and burden of car owners, manufacturing cost and weight increase of car body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

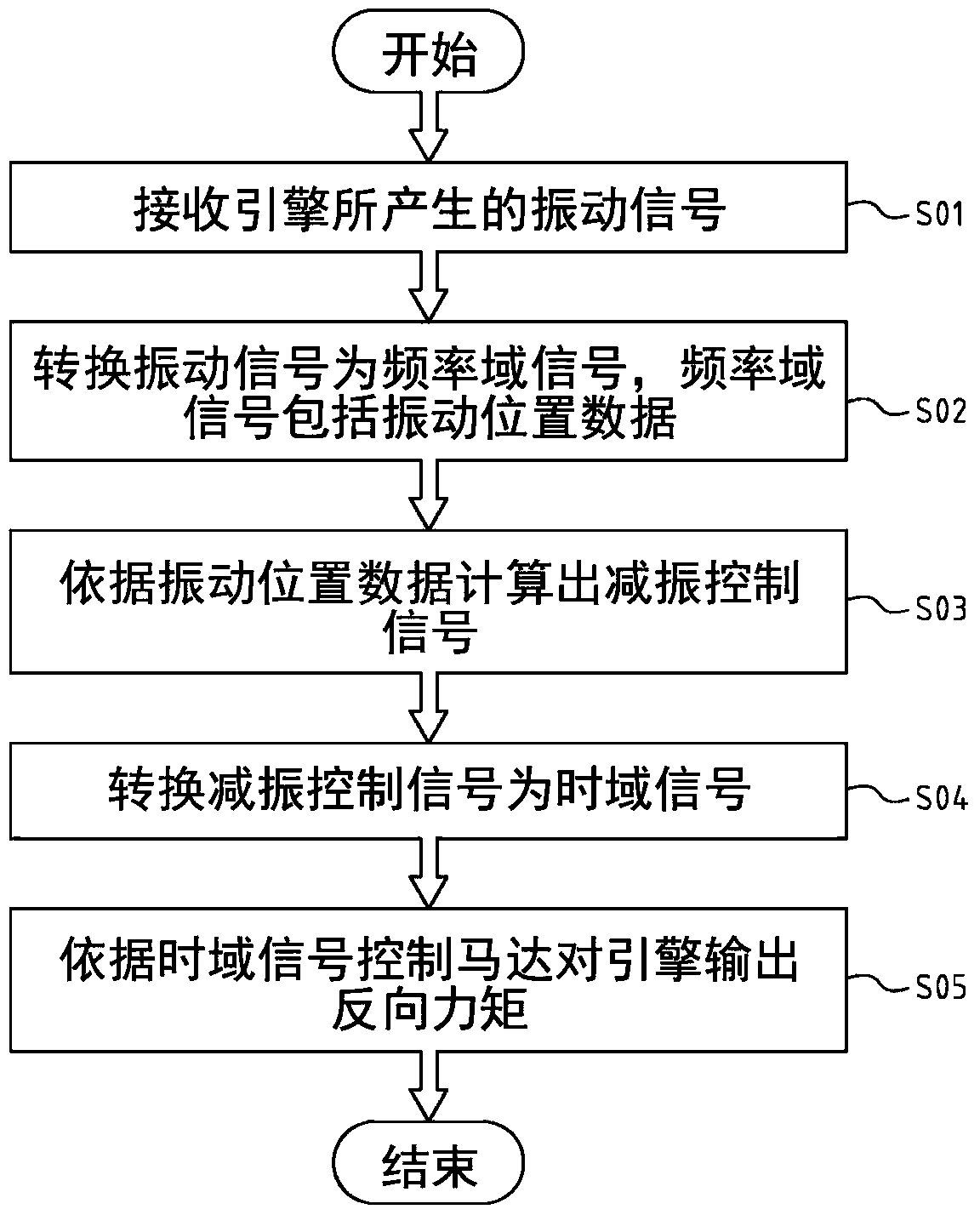

[0042] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

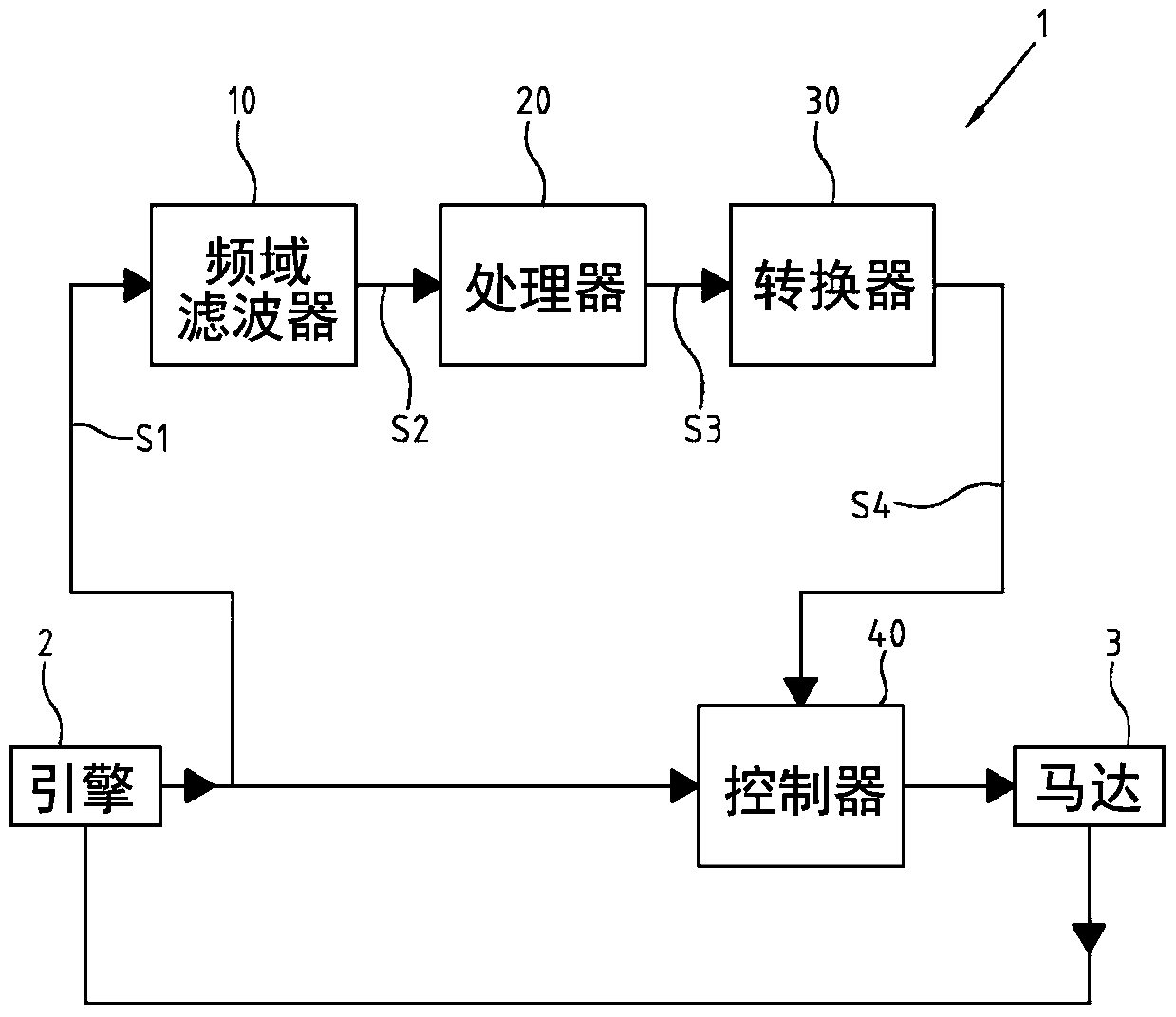

[0043] Such as figure 1 Shown is the device block diagram of the engine vibration damping control device of the present invention. The engine vibration damping control device 1 is connected to the engine 2 and the motor 3 to drive the motor 3 to achieve the purpose of damping the engine 2 . The engine vibration reduction control device 1 includes a frequency domain filter 10 , a processor 20 , a converter 30 and a controller 40 . The above-mentioned motor 3 may be a belt-alternator starter generator or an integrated starter motor (Integrated Starter Generator).

[0044] The above-mentioned frequency domain filter 10 (frequency sampling filter) receives the vibration signal S1 generated by the engine 2 and converts the vibration signal S1 into a frequency domain signal S2, wherein the frequency domain signal S2 includes vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com