Test piece mechanical strength fixtures used for manufacturing high-strength structural adhesive and application method

A technology of mechanical strength and structural glue, which is applied in the field of mechanical strength fixtures of test pieces, can solve problems such as inaccurate tensile values, inability to perform torque tests, and unqualified products, and achieve the effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

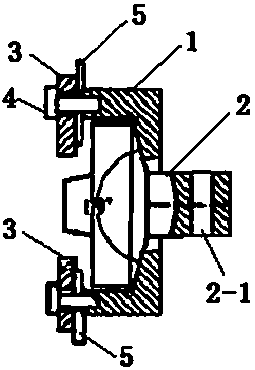

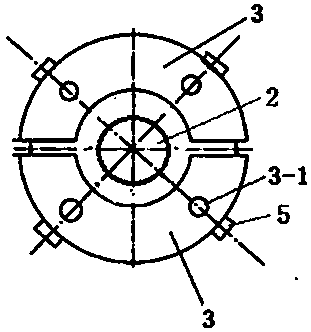

[0025] Such as Figure 1 to Figure 4 As shown, the mechanical strength fixture of the test piece used to manufacture high-strength structural adhesives includes a jacket 1, a seat 2, a pressure plate 3, a bolt 4, and a gasket 5.

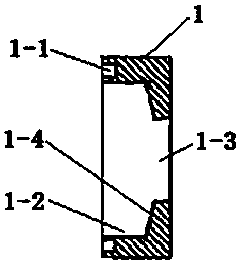

[0026] The outer casing 1 is circular, and four blind screw holes 1-1 and one circular groove 1-2 are respectively provided on one end surface of the outer casing 1, and a circular groove 1-2 is provided on the other end surface of the outer casing 1 to communicate with the groove 1-2. The hole 1-3, the inner bottom surface of the circular groove 1-2 is a tapered surface I1-4.

[0027] One end of the seat 2 is a short cylinder 2-1 with an inclined surface, the other end is a long cylinder 2-2, and between the cylinder and the long cylinder is a circular block 2-3, which is connected with the long cylinder 2-2. The connected circular block surfaces are conical surfaces II 2-4, and the long cylinders are provided with pin holes 2-5.

[0028] The top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com