Ultra-pure silver powder preparation method capable of controlling particle size

A technology of pure silver and particle size, which is applied in the field of preparation of ultra-pure silver powder, can solve the problems of not allowing addition, and achieve the effects of mild reaction temperature, simple reaction raw materials, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

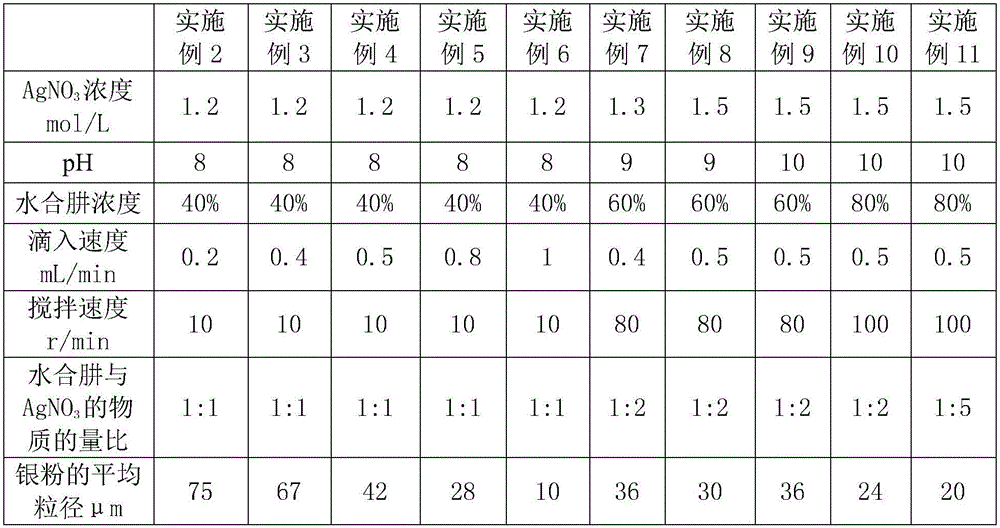

Examples

Embodiment 1

[0025] A preparation method of ultra-pure silver powder with controllable particle size, comprising the following steps:

[0026] (1) silver nitrate solution is prepared, and the concentration of silver nitrate in the solution is 1.2mol / L;

[0027] (2) add ammoniacal liquor in the silver nitrate solution prepared in step (1), adjust pH to 8;

[0028] (3) At normal temperature, the aqueous solution of hydrazine hydrate with a concentration of 40% is dripped into the silver-ammonia solution of step (2) with a speed of 0.1mL / min with a precision flowmeter, and the stirring speed is 10r / min, to obtain Silver powder slurry, wherein the mass ratio of hydrazine hydrate to silver nitrate is 1:1.

[0029] (4) filter the silver powder slurry that step (3) obtains and wash with deionized water, repeat 3 times, obtain silver powder after the wet silver powder obtained after filtering is dried under nitrogen protection, the average particle diameter of silver powder is 2 μ m, and purity i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com