Electric-heating riveting device for automobile parts

An auto parts and electric heating technology, which is applied in the field of auto parts processing, can solve problems such as rivet percussion bending, difficult end riveting, etc., to achieve safe and effective use, improve the consistency of processing quality, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

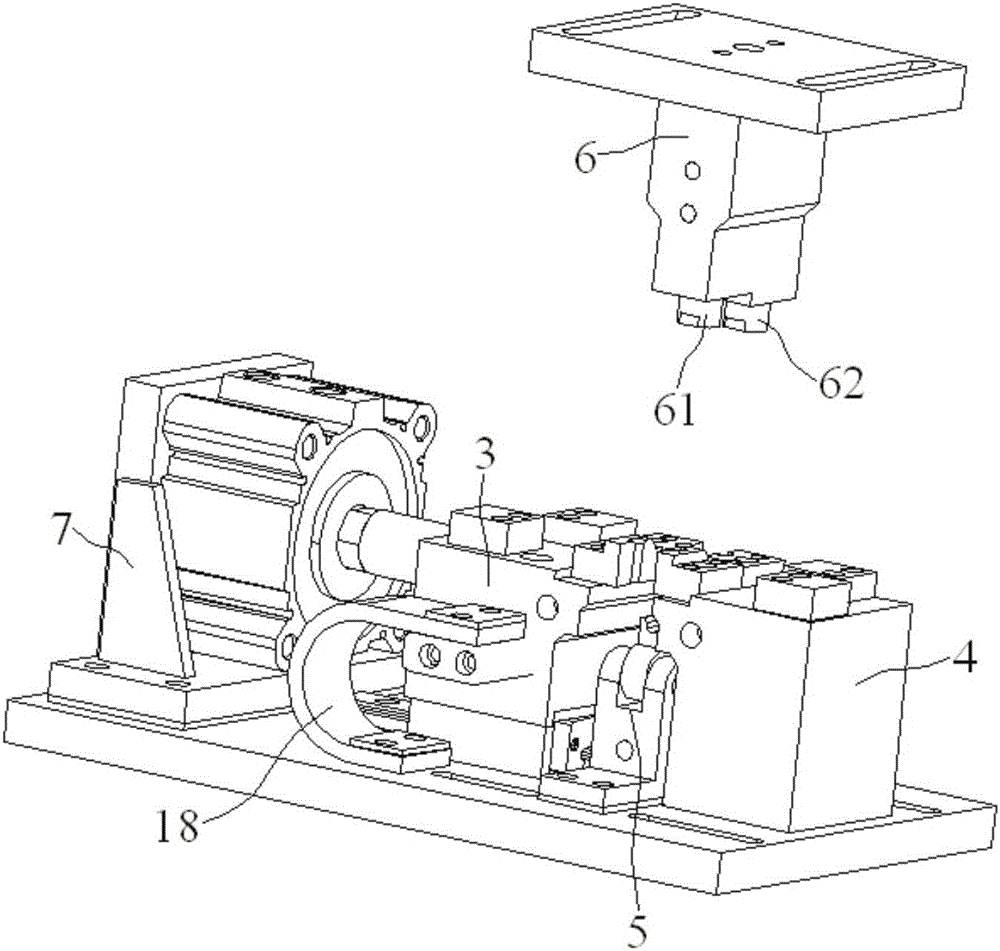

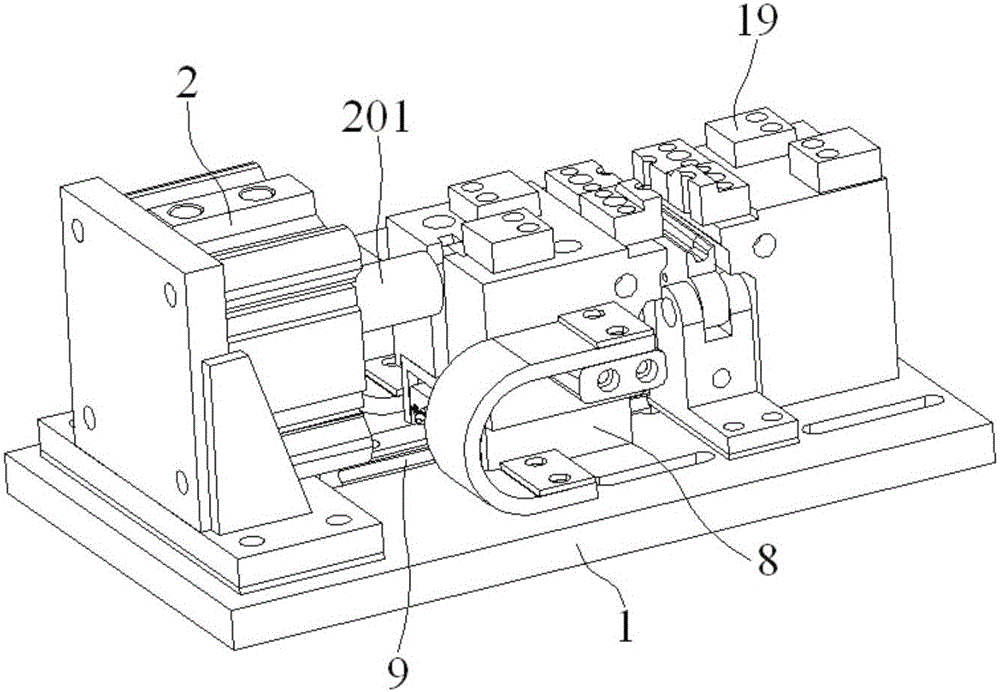

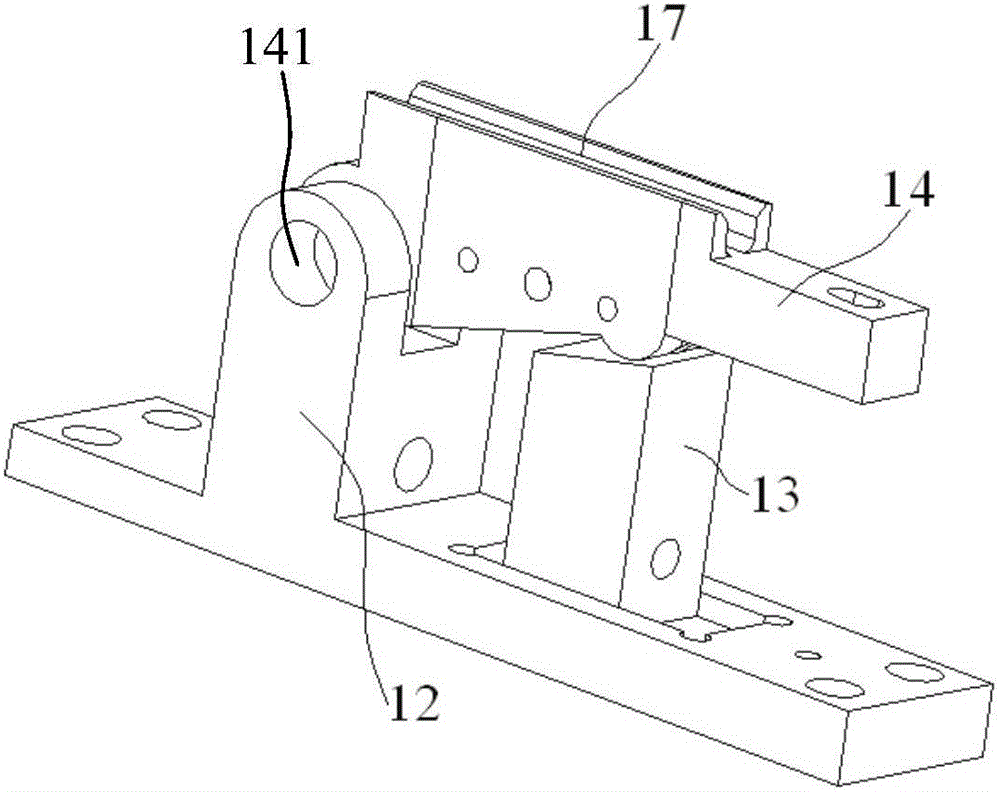

[0021] Embodiment 1: An electric heat riveting device for auto parts, including a base 1, a cylinder 2, a left clamping seat 3, a right clamping seat 4, a positioning mechanism 5 and a riveting head mechanism 6, the base 1 One end upper surface is fixed with a mounting bracket 7, the cylinder 2 is fixed on the side surface of the mounting bracket 7, the left clamping seat 3 is installed on a slide rail 9 through a slide block 8, and the right clamping seat 4 is fixed on the other end of the base 1, the left clamping seat 3 is located between the cylinder 2 and the right clamping seat 4 and the piston rod 201 of the cylinder 2 is connected to the left clamping seat 3, and the positioning mechanism 5 is located in the left clamping seat 4 Between the holding seat 3 and the right holding seat 4, the riveting head mechanism 6 is located directly above the positioning mechanism 5, and the riveting parts are placed on the upper surfaces of the left holding seat 3 and the right holdin...

Embodiment 2

[0026] Embodiment 2: An electric heat riveting device for auto parts, including a base 1, a cylinder 2, a left clamping seat 3, a right clamping seat 4, a positioning mechanism 5 and a riveting head mechanism 6, the base 1 One end upper surface is fixed with a mounting bracket 7, the cylinder 2 is fixed on the side surface of the mounting bracket 7, the left clamping seat 3 is installed on a slide rail 9 through a slide block 8, and the right clamping seat 4 is fixed on the other end of the base 1, the left clamping seat 3 is located between the cylinder 2 and the right clamping seat 4 and the piston rod 201 of the cylinder 2 is connected to the left clamping seat 3, and the positioning mechanism 5 is located in the left clamping seat 4 Between the holding seat 3 and the right holding seat 4, the riveting head mechanism 6 is located directly above the positioning mechanism 5, and the riveting parts are placed on the upper surfaces of the left holding seat 3 and the right holdin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com