No-tillage electronic control corn compound planter

A corn seeder and seeder technology, applied in the fields of fertilizers and seeding equipment, horticulture, botanical equipment and methods, etc., can solve the problems of missing seeding, affecting the work of seed metering devices, and not being able to meet the needs of modern agricultural precision sowing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

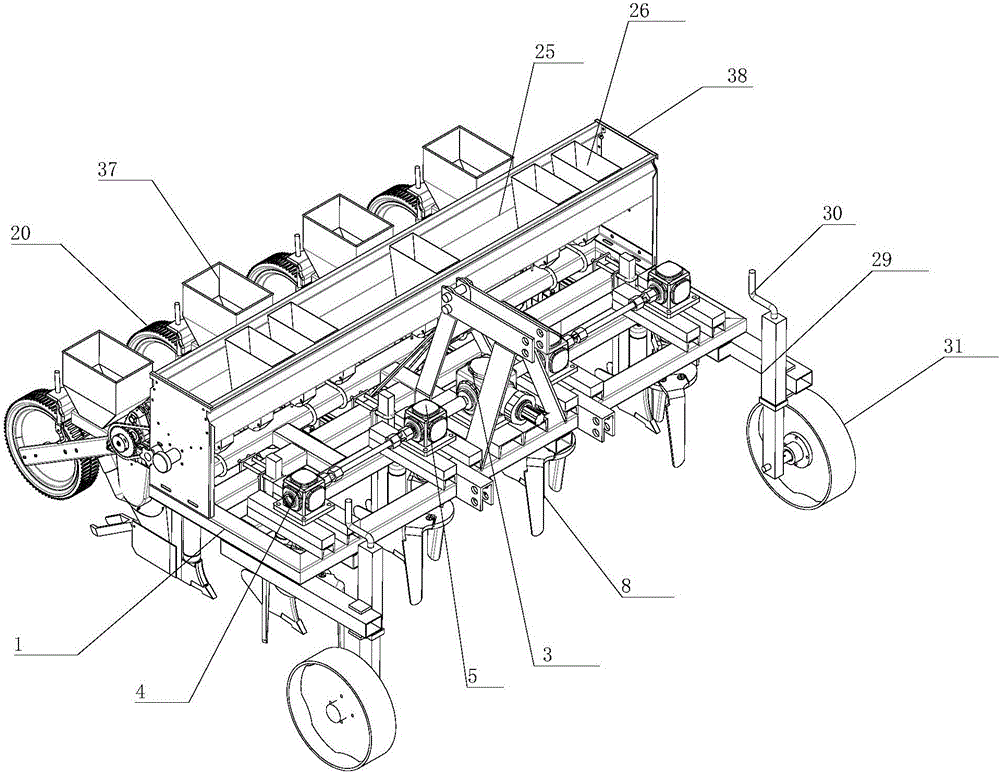

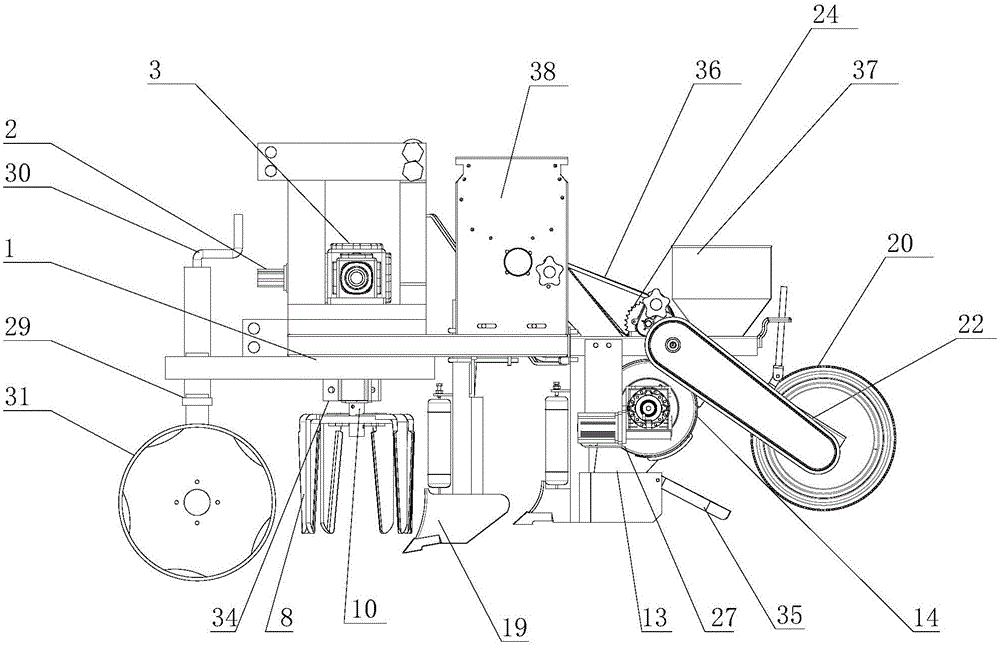

[0020] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , the present invention proposes a no-tillage electronically controlled corn compound seeder, comprising a frame 1, a knife-turning cleaning mechanism, a seeding mechanism, a fertilizer discharge mechanism, a depth-limiting wheel height adjustment mechanism, a knife-drawing cleaning mechanism, a seeding mechanism, a row The fertilizer discharge mechanism and the height adjustment mechanism of the depth-limiting wheel are all installed on the frame 1, wherein:

[0021] The knife-drawing cleaning mechanism includes a spline input shaft 2, a reducer 3, a single-output commutator 4, a double-output commutator 5, a universal joint 6, a universal joint connecting shaft 7, a vertical rotary knife-drawing 8, a knife Disc 9, cutter shaft 10, spline input shaft 2 is in transmission connection with reducer 3, reducer 3 is in transmission connection with double output commutator 5, one end of universa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com