Rotary dehumidifier-type condensation dehumidification device for metal-clad equipment and control method of rotary dehumidifier-type condensation dehumidification device

A rotary dehumidifier and metal armoring technology, applied in the direction of humidity control, non-electric variable control, control/regulation system, etc., can solve the problem of fast aging of electric heating devices, shortening the service life of insulating materials, and uneven internal temperature distribution To achieve the effect of ensuring safe and stable operation and removing condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

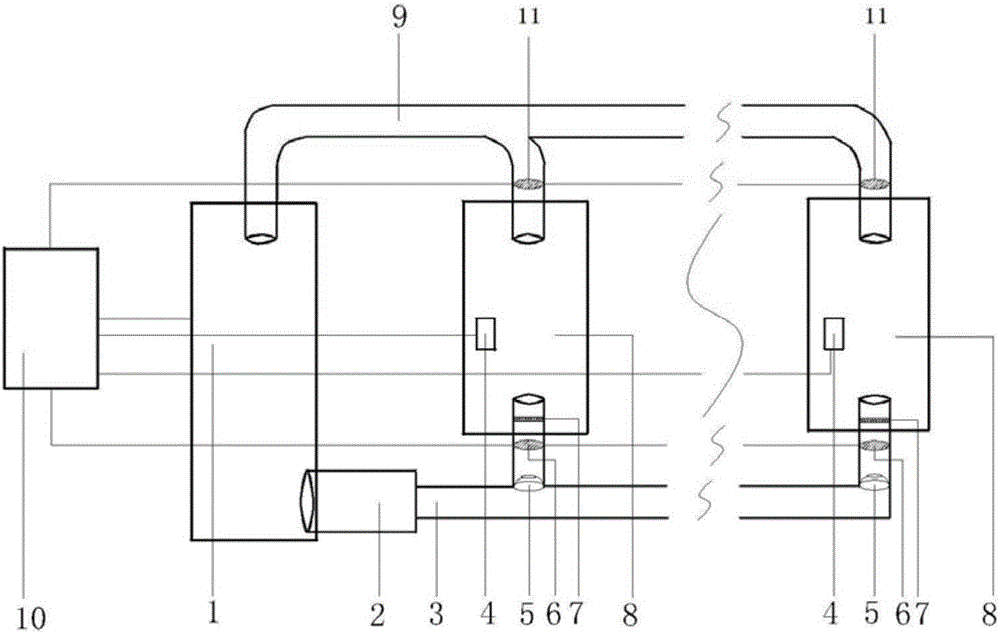

[0050] The rotary dehumidifier 1 is produced by Wuxi Yongbang Dehumidification Equipment Co., Ltd., the model is ZCM-350, and the rated humidity is 4.8kg / h; the static pressure box 2 is made of 304 stainless steel plate; the air inlet pipe 3 and the return air pipe 9 is self-processed with 304 stainless steel; the temperature and humidity meter 4 is the W4052 temperature and humidity transmitter produced by Tean Instrument Equipment Co., Ltd., the temperature measurement range is -40 ° C ~ 150 ° C, and the relative humidity measurement range is 5% ~ 110%; The spherical air outlet 5 is produced by Shanghai Eponair Ventilation Equipment Co., Ltd., the model is TE065, and the diameter of the air outlet is 80mm; the air inlet valve 6 and the return air valve 11 adopt the D941W electric ventilation butterfly valve produced by Wuhan Great Control Valve Co., Ltd. ;Grille wind deflector 7 is processed by 304 stainless steel plate; metal armored equipment 8 is KYN28A 10kV switch cabinet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com