Steel tape thickness detection device having no influences on production process

A thickness detection and production process technology, applied in measuring devices, instruments, etc., can solve problems such as error-prone, inconvenient detection, and influence on the accuracy of steel strip thickness detection, to prevent the threat of electric shock, avoid inaccurate measurement, Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

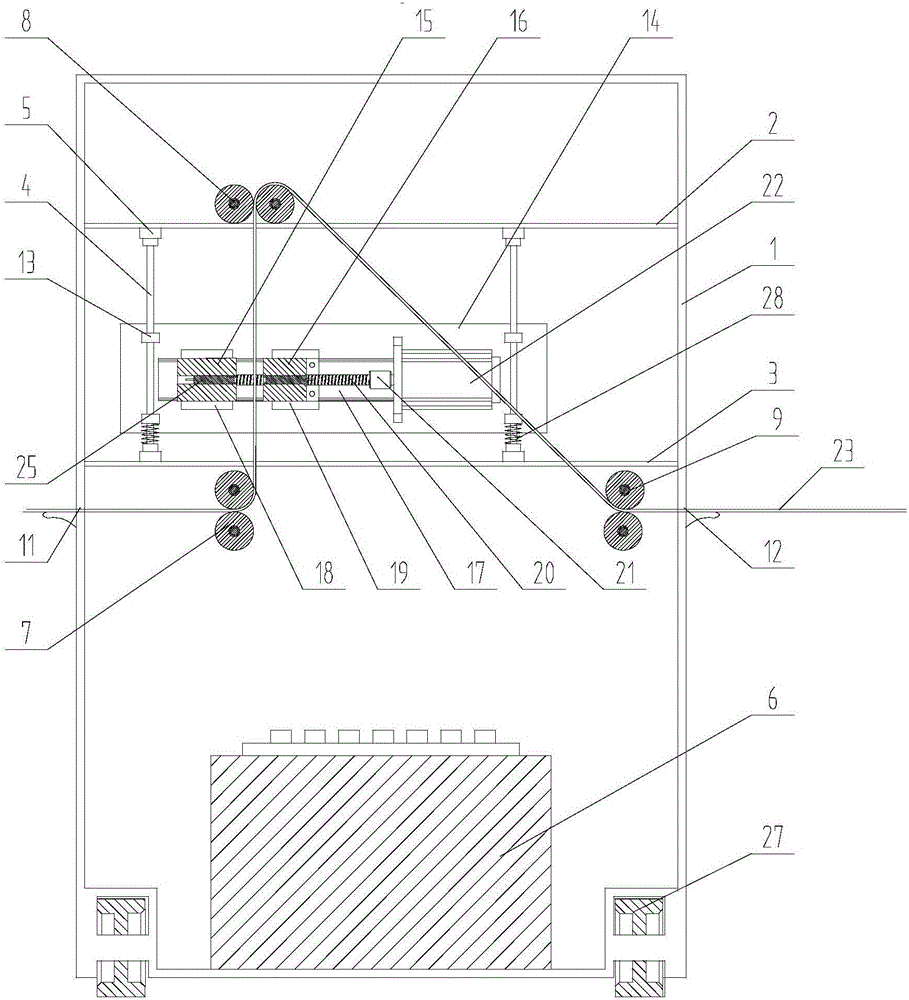

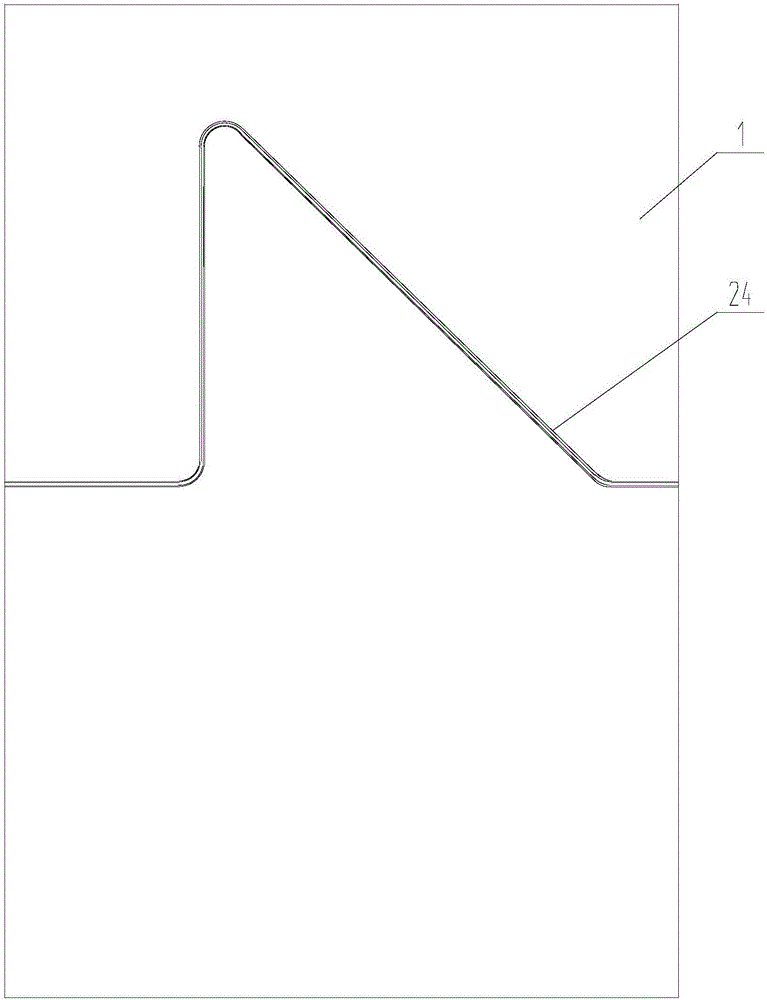

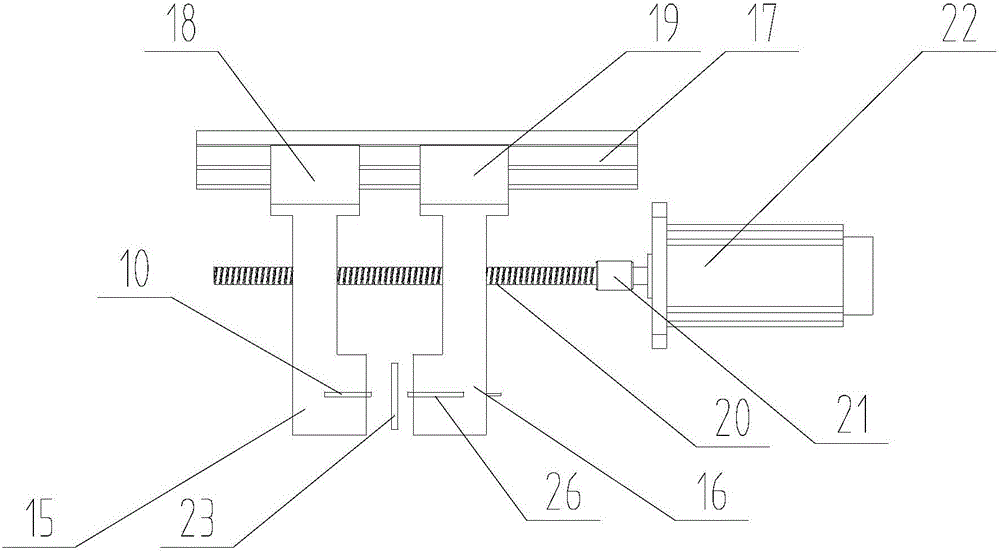

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

[0031] refer to Figure 1-3As shown, a steel strip thickness detection device of the present invention that does not affect the production process includes a box-type housing 1, an upper support plate 2, a lower support plate 3, a linear guide rail 4, a follow-up detection device, a pressure detection device, and a rechargeable battery 6 and three pairs of transmission roller groups, the three pairs of transmission roller groups are respectively the first transmission roller group 7, the second transmission roller group 8, and the third transmission roller group 9, and the three pairs of transmission roller groups are fixed in the shape of a right triangle Inside the box-type housing, the second transmission roller group 8 is arranged directly above the first transmission roller group 7, and the third transmission roller group 9 is located on the same level as the first tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com