Classified-combustion fuel gas low-nitrogen combustor

A low-nitrogen burner and staged combustion technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as unreasonable structure of burners, failure of reasonable mixing of fuel gas and combustion-supporting air, and failure to meet environmental protection requirements. , to achieve the effect of wide practicability, simple structure, reducing concentration and oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

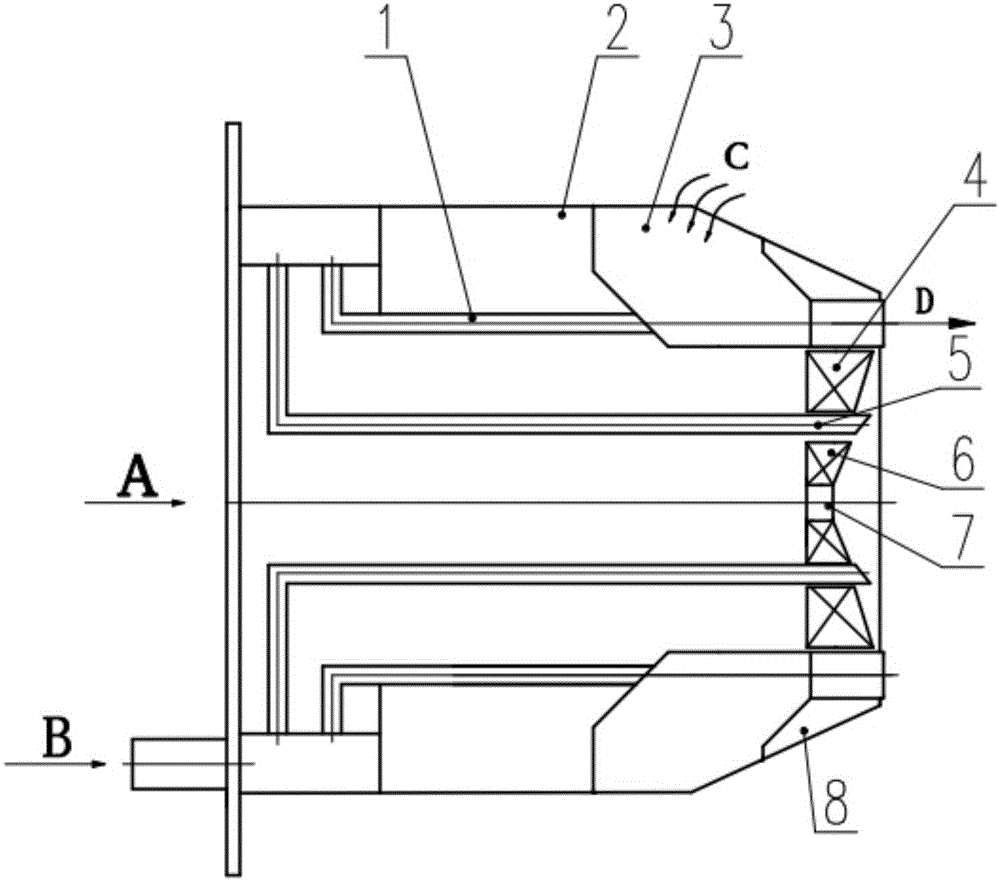

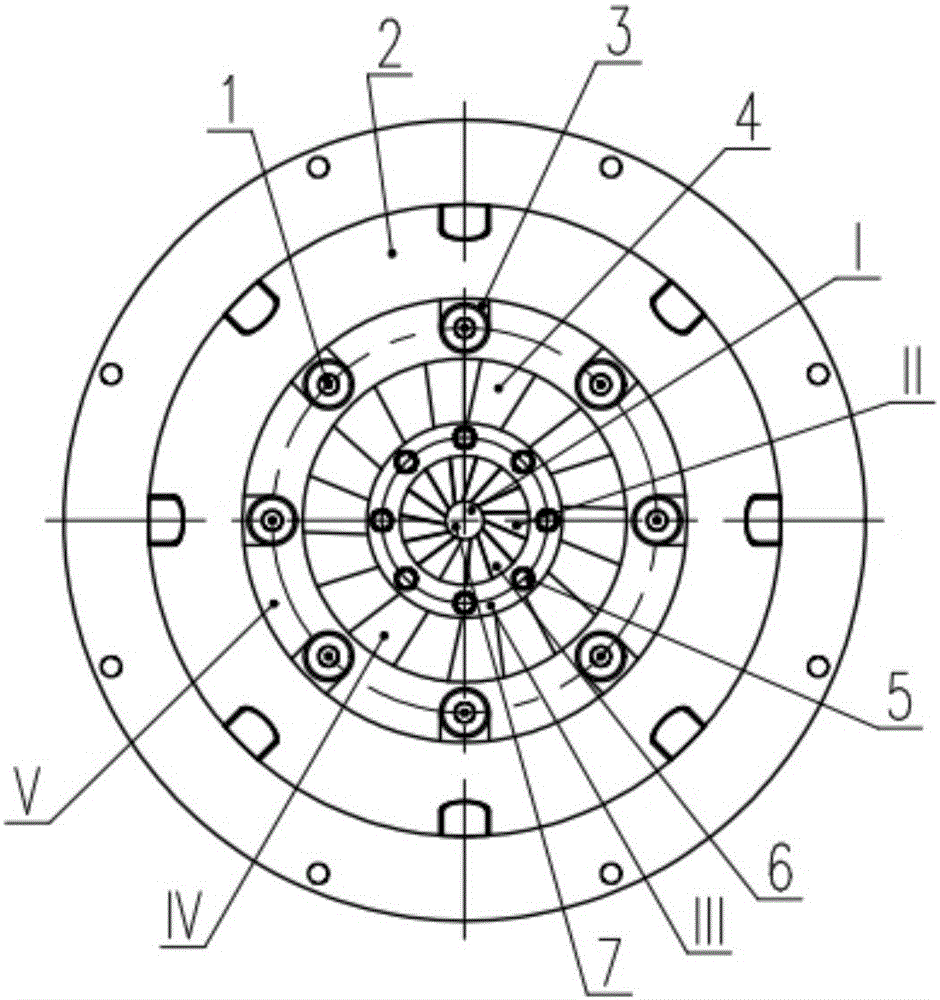

[0018] The staged combustion gas low-nitrogen burner of the present invention is mainly composed of a secondary fuel spray gun 1, a combustion-supporting air channel 2, a flue gas internal circulation ejection pipe 3, a secondary cyclone air channel 4, and a primary fuel arranged in a necked cylinder. The spray gun 5, the primary cyclone air channel 6, the central direct current air channel 7 and the necked nozzle 8 are composed; the central direct current air channel 7 is set in the center of the necked nozzle 8, and the combustion-supporting air diffuses and sprays in a straight line along the axial direction. Hollow flame; the primary cyclone air channel 6, the secondary cyclone air channel 4 are arranged on the outer side of the central DC air channel 7; the central DC air channel 7, the primary cyclonic air channel 6 and the secondary cyclonic air cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com