Rotary joint for water-cooled roller

A technology of rotary joint and water-cooling roller, applied in the direction of pipe/pipe joint/pipe fitting, adjustable connection, passing element, etc., can solve the problems of aggravating the wear, damage and rapid wear of the sealing ring, so as to prolong the service life and ensure the operation. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

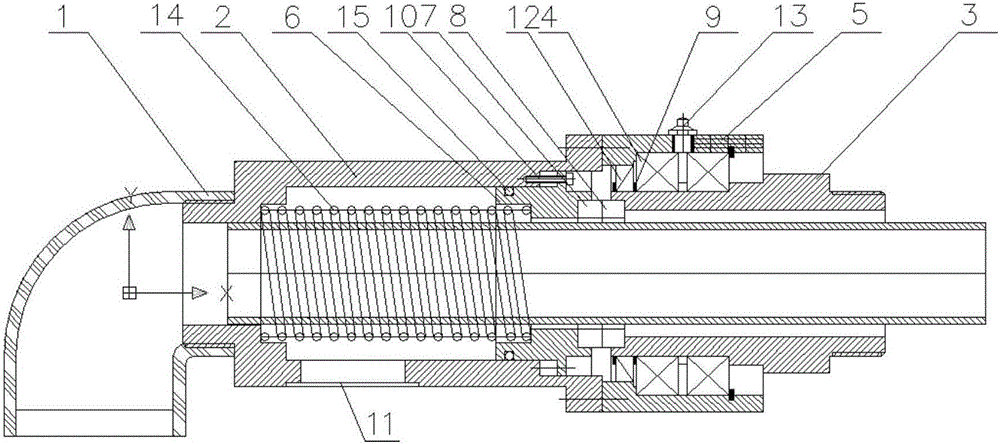

[0016] Such as figure 1 As shown, a rotary joint for water-cooled rollers includes a fixed joint 1, a fixed housing 2, a rotating housing 3, a bearing 4, a bearing seat 5, a spring 14, a sliding seat 6, a fixed sealing ring 7 and a rotating sealing ring 8. One end of the fixed joint and the fixed shell is connected by thread, and the other end of the fixed shell is connected with the bearing seat. The bearing is set between the bearing seat and the rotating shell, and is connected by the retaining ring 9. The sliding seat is adjusted by the adjusting bolt. 10 is fixed on the inner wall of the fixed housing, an O-ring 15 is provided between the sliding seat and the inner wall of the fixed housing, and a lubricating oil nozzle 13 is provided on the bearing seat. The sliding seat can slide a certain dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com