Panel connection method

A technology of plate connection and plate, which is applied in the direction of thin plate connection, connecting components, mechanical equipment, etc., can solve the problems of easy falling off and damage, uneven plate surface, easy damage, etc., and achieve the effect of thickness guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

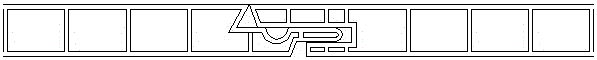

[0051] see Figure 1 ~ Figure 3 , Embodiment 1 includes A board 1 and B board 2.

[0052] After the A board 1 is installed, the front side 3 of the A board 1 faces outwards and is exposed, and a decorative structure can be arranged on the front side 3 of the A board 1; .

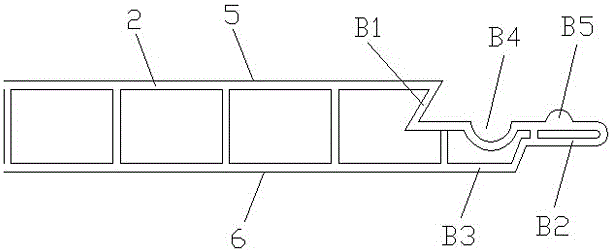

[0053] After the B-board 2 is installed, the front side 5 of the B-board 2 is outwardly exposed, and a decorative structure can be arranged on the front side 5 of the B-board 2; .

[0054] A concave butt end is provided on one side of the A board 1 . The concave butt end includes an upper edge end A1, a docking port A2 and a lower edge end A3.

[0055] The upper edge A1 and the lower edge A3 are fixed on one side of the A board 1 and can be integrally formed with the A board 1 . The upper edge A1 is close to the front face 3 of the A board 1, and the front face of the upper edge A1 is flush with the front face 3 of the A board 1, so that unevenness will not be caused.

[0056] The thickness of the upper ...

Embodiment 2

[0071] see Figure 4 ~ Figure 6 , Embodiment 2 On the basis of Embodiment 1, a clamping block B5 is fixedly arranged on the lower edge butt joint end B2, and a clamping slot A4 is opened on the upper edge end A1, and the clamping block B5 cooperates with the clamping slot A4. When the convex butt ends are spliced, the clamping block B5 and the clamping slot A4 are clamped.

Embodiment 3

[0073] see Figure 7 ~ Figure 9 , the difference between embodiment 3 and embodiment 1 is that when the concave butt end and the convex butt end are spliced, the upper edge butt end B1 and the upper edge end A1 are opposite but not in contact, and the gap between the two can be used for installation Construction and decoration materials such as stickers and metal strips. The gap can be formed by keeping the width of the upper edge end A1 constant and the upper edge butt end B1 retracting backward, so that the production of the product is simpler and the product firmness is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com