Vertical slab quenching machine and quenching method

A vertical quenching machine technology, applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of inconsistent steel plate quality, uneven steel plate structure, large investment cost, etc., to eliminate internal structure inhomogeneity, shorten the cost Effect of quenching medium time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] The product object processed in this example is a hydrogen-facing steel plate with a length of 13800mm, a width of 1800mm, and a thickness of 180mm. It is required to obtain martensite and lower bainite structures along the entire cross-section after quenching and cooling, and the distortion must be controlled within a certain range.

[0019] In order to avoid cracking during the quenching process, the water-air alternate time-controlled quenching and cooling process is adopted, that is, the water quenching + air cooling process is performed under the premise of strictly controlling the time.

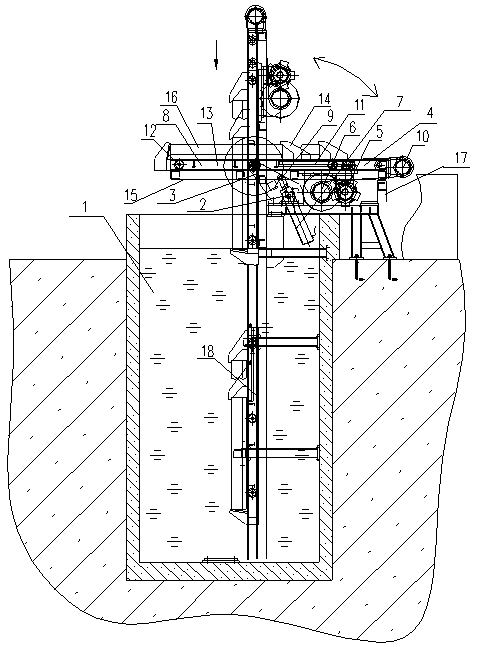

[0020] Such as figure 1 Shown is the vertical slab quenching machine used for water quenching, which is suspended and set on the upper side of the quenching medium pool body, including the turning platform 4, the turning platform base 15, the mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com