Grease, rolling bearing, rolling bearing device, and information recording and reproducing apparatus

一种滚动轴承、润滑脂的技术,应用在滚动轴承装置和信息记录重放装置,滚动轴承,润滑脂领域,能够解决难以得到耐久性滚动轴承等问题,达到优异耐久性、减少脱气量、耐久性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0182] Refined mineral oil (classified as Group III mineral oil in the API base oil category with a mass ratio of 3:7. The kinematic viscosity is ν 1 =47mm 2 / s (40°C), mineral oil with a flash point above 250°C) and PAO (a mixture of 3-5 polymers of α-olefins with 8-12 carbon atoms, the kinematic viscosity is ν 2 =30mm 2 / s(40℃)) mixed as base oil (kinematic viscosity ν=34mm 2 / s(40℃)).

[0183] Next, using the above-mentioned base oil and a cycloaliphatic diurea compound as a thickener, it is greased, and an antioxidant and a rust inhibitor are added and mixed. The ratio of each component was 86.0 mass % of base oil, 12.5 mass % of thickener, 0.5 mass % of antioxidant, and 1.0 mass % of rust inhibitor with respect to 100 mass % of grease.

Embodiment 2

[0185] The above-mentioned base oil and a cycloaliphatic diurea compound as a thickener were used for greasing, and a mixed extreme pressure agent was further added in addition to the antioxidant and rust inhibitor, and the same implementation as in Example 1 was carried out. The ratio of each component is: 85.0% by mass of base oil, 12.5% by mass of thickener, 0.5% by mass of antioxidant, 1.0% by mass of rust inhibitor, and 1.0% by mass of extreme pressure agent, based on 100% by mass of grease. quality%.

reference example 1

[0193] As the grease, a commercially available rolling bearing grease α for an information recording and reproducing device was prepared. In addition, grease α contains a urea compound as a thickener.

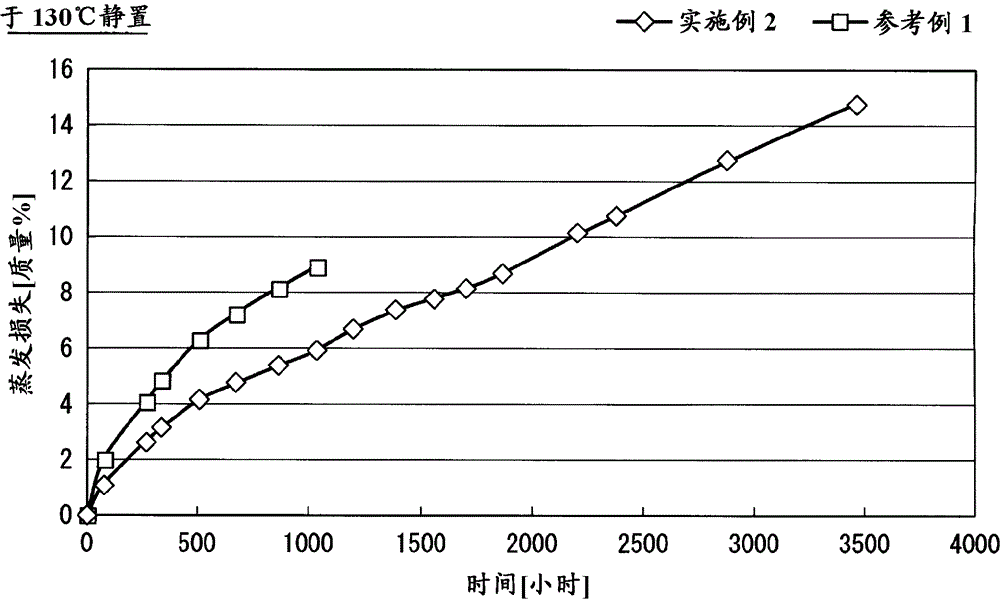

[0194] Table 1 shows the results of outgassing measurement, durability test, and grease bump test in each of Examples and Comparative Examples. In addition, the results of the low-temperature torque test of the greases of Example 2 and Reference Example 1 are shown in Table 2, and the results of the long-term evaporation loss test are shown in Figure 7~9 middle.

[0195] [Table 1]

[0196]

[0197] [Table 2]

[0198]

[0199] As shown in Tables 1 and 2, including kinematic viscosity ν used at the ratio of the present invention 1 kinematic viscosity ν of PAO 2 The greases of Examples 1 and 2, which are high mineral oil base oils, had a small amount of outgassing. In addition, in Examples 1 and 2, there was little variation in torque in any of the durability test and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com