Modified silica nanoparticles and preparation method thereof and drilling fluid suitable for shale gas well

A silicon dioxide and nanoparticle technology, applied in the field of oil drilling fluid, can solve the problems of increasing fine particles, increasing drilling fluid, damaging oil and gas layers, etc., and achieving the effect of not easy to agglomerate and good blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a method for preparing modified silica nanoparticles, the method comprising:

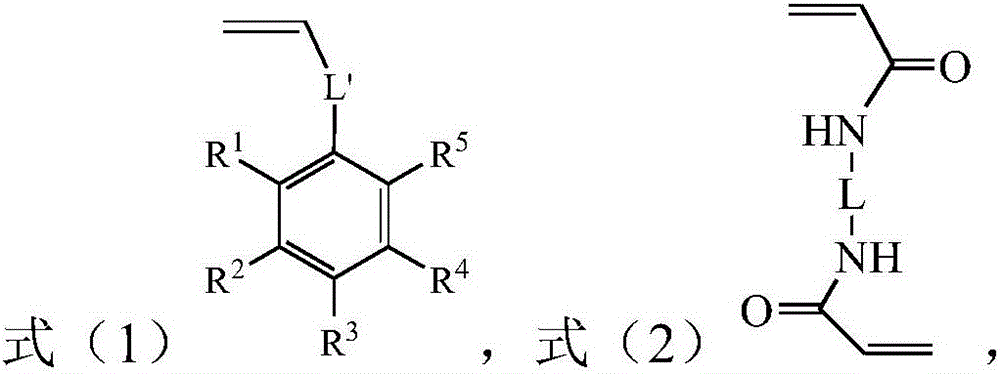

[0050] (1) In the presence of a monohydric alcohol and a coupling agent, combine one or more of the monomers of the structure represented by formula (1) and one or more of the monomers of the structure represented by formula (2) with two Silicon oxide nanoparticles undergo contact reaction;

[0051] (2) In the presence of a redox initiation system, subject the product of the contact reaction to a polymerization reaction;

[0052]

[0053] Where R 1 -R 5 One of them is -L"-SO 3 H and the rest are each independently selected from H, -OH, halogen, and C1-C10 alkyl; L, L'and L" are each independently selected from C0-C10 alkylene.

[0054] According to the present invention, the above formula (1) and formula (2) and the groups involved in them are as described above, and will not be repeated here.

[0055] According to the present invention, in step (1), the amount of m...

Embodiment 1

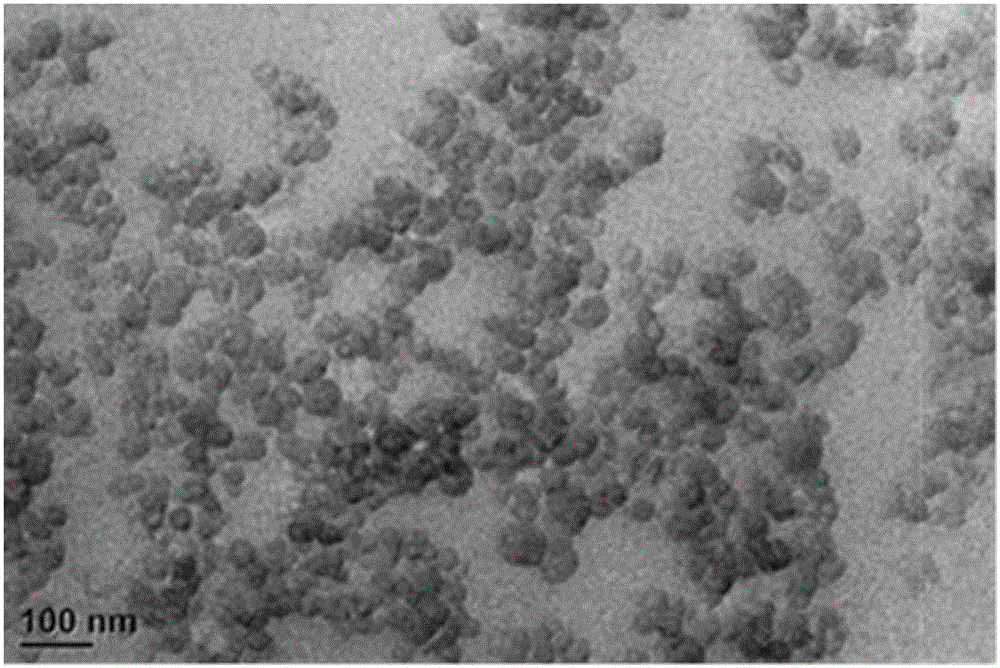

[0090] This example is used to illustrate the modified silica nanoparticles of the present invention and the preparation method thereof.

[0091] (1) Stir 0.12mol of p-styrenesulfonic acid and 0.19mol of N,N'-methylenebisacrylamide (purchased from Huantai County Taili Chemical Co., Ltd.) for 30min at about 25°C and 300rpm , And adjust the pH to 7 with sodium hydroxide to obtain mixture A1; mix 0.5 g of silica nanoparticles (purchased from Nanjing Tianxing New Material Co., Ltd. TSP brand, particle size is about 20nm) and 8g of n-propanol in about Stir for 30 minutes at 25°C and 300 rpm to obtain mixture B1; stir mixture A1 and mixture B1 at about 25°C and 300 rpm for 30 minutes to obtain mixture C1;

[0092] (2) Mix 0.01g of coupling agent γ-aminopropyltriethoxysilane (purchased from Huantai Taili Chemical Co., Ltd. KH550 brand) with the above mixture C1 and react at 60°C and 200rpm stirring for 30min ; Then add 0.094g of the redox initiation system (composed of sodium bisulfite a...

Embodiment 2

[0096] This example is used to illustrate the modified silica nanoparticles of the present invention and the preparation method thereof.

[0097] (1) Stir 0.15 mol of p-styrene sulfonic acid and 0.2 mol of N,N'-methylene bisacrylamide (purchased from Huantai Taili Chemical Co., Ltd.) for 25 min at about 30°C and 250 rpm , And adjust the pH to 7.5 with sodium hydroxide to obtain a mixture A2; 1g of silica nanoparticles (purchased from Nanjing Tianxing New Material Co., Ltd. TSP brand, particle size is about 20nm) and 8g of isopropanol in about 30 Stir at 250 rpm for 25 min at ℃ to obtain mixture B2; Stir mixture A2 and mixture B2 at about 30 ℃ and at 250 rpm for 25 min to obtain mixture C2;

[0098] (2) Mix 0.012g of coupling agent γ-aminopropyltriethoxysilane (purchased from Huantai Taili Chemical Co., Ltd. KH550 brand) with the above mixture C2 and react at 50°C and 250rpm for 30min ; Then add 0.094g of the redox initiation system (composed of sodium bisulfite and ammonium persul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com