Cloth rolling machine bringing convenience to reading of length of rolled cloth

A technology of fabric length and cloth winding machine, which is applied in the direction of winding strips, thin material processing, sending objects, etc. The effect of volume quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

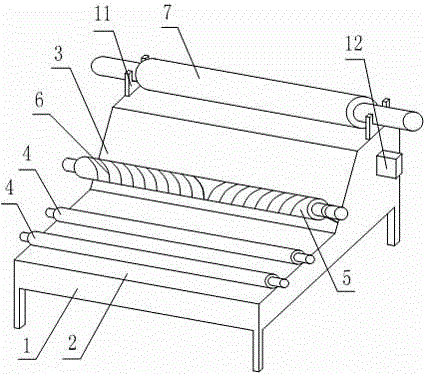

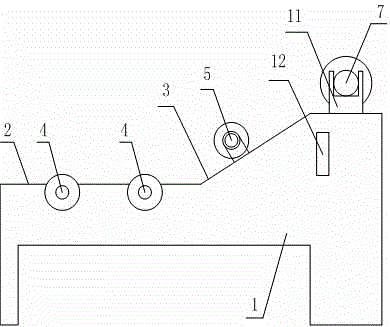

[0020] Such as figure 1 and figure 2 The cloth rolling machine shown is convenient for reading the length of the rolled cloth, including a frame 1, a plane 2 is arranged on the frame 1, and a slope 3 inclined upward from the plane 2, the plane 2 of the frame 1 At least two first cloth guide rollers 4 are arranged on the frame 1, and a second cloth guide roller 5 is arranged on the inclined surface 3 of the frame 1, and the first cloth guide roller 4 and the second cloth guide roller 5 are all parallel to the plane 2 and the intersection line of the slope 3, the surface of the second cloth guide roller 5 is wound with a spiral filament-shaped protrusion 6 propagating from the axial center line to both ends; the top of the slope 3 is provided with a cloth rolling roller 7, and the first A cloth guide roller 4 rotates toward the direction that the top is close to the inclined surface 3, the second cloth guide roller 5 rotates in the same direction as the first cloth guide rolle...

Embodiment 2

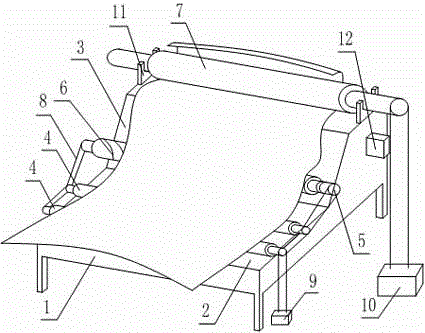

[0022] Such as image 3The cloth rolling machine shown is convenient for reading the length of rolled cloth. On the basis of Embodiment 1, the first cloth guide roller 4 and the second cloth guide roller 5 are linked by a belt 8; the first cloth guide roller 4. The second cloth guide roller 5 is driven by the first motor 9, and the cloth rolling roller 7 is driven by the second motor 10; the first motor 9 and the second motor 10 have the same speed; the number of turns counter is Hall sensor or induction pulse coil. Since the second cloth guide roller 5 and the first cloth guide roller 4 rotate in the same direction, the first cloth guide roller 4 and the second cloth guide roller 5 are linked through the belt 8, so that the two groups of cloth guide rollers can move synchronously , further simplify the structure of the present invention, and facilitate the user to control the cloth guide roller. The first cloth guide roller 4 and the second cloth guide roller 5 are driven b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com