Nozzle used for printed circuit board cleaning machine

A technology for printed circuit boards and cleaning machines, applied in the direction of liquid cleaning methods, spray devices, spray devices, etc., can solve the problems of difficult installation, disassembly, and replacement, and achieve simple structure, reduced water pressure loss, and cleaning The effect of high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

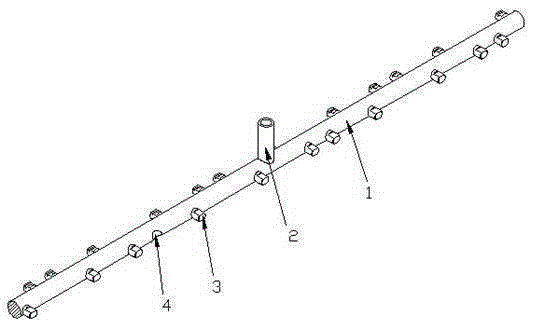

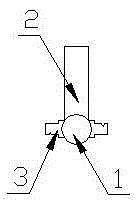

[0022] Such as Figure 1-4 As shown, a nozzle for a printed circuit board cleaning machine includes a high-pressure water delivery pipe 2, the high-pressure water delivery pipe 2 is fixedly connected with a spray arm 1, and several screw holes are arranged on both sides of the spray arm 1 4. A nozzle 3 is screwed inside the screw hole 4;

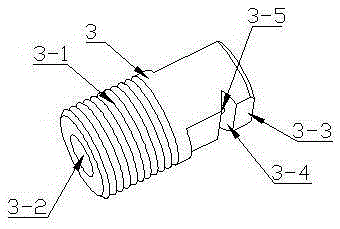

[0023] The outer end of the nozzle 3 is provided with several assembly platforms 3-3, and the surface of at least one of the assembly platforms 3-3 is provided with at least one V-shaped groove 3-4, and the groove of the V-shaped groove 3-4 A water outlet hole 3-5 is provided in the lower and middle part; the diameter of the water inlet hole 3-2 is processed according to the design size, and the assembly platform 3-3 is processed according to the required size of the assembly platform 3-3 and installed on the assembly platform 3-3 according to the design Angle and depth After the V-shaped groove 3-4 is processed, the middle part of the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com