Steam jacketed kettle

A sandwich pot and steam technology, which is applied in the field of kitchen utensils, can solve the problems of complex and rough heating structure and heat preservation structure, poor reliability of steam sandwich pot, and low heating efficiency of the pot body, so as to achieve stable pot structure, simple structure and low energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

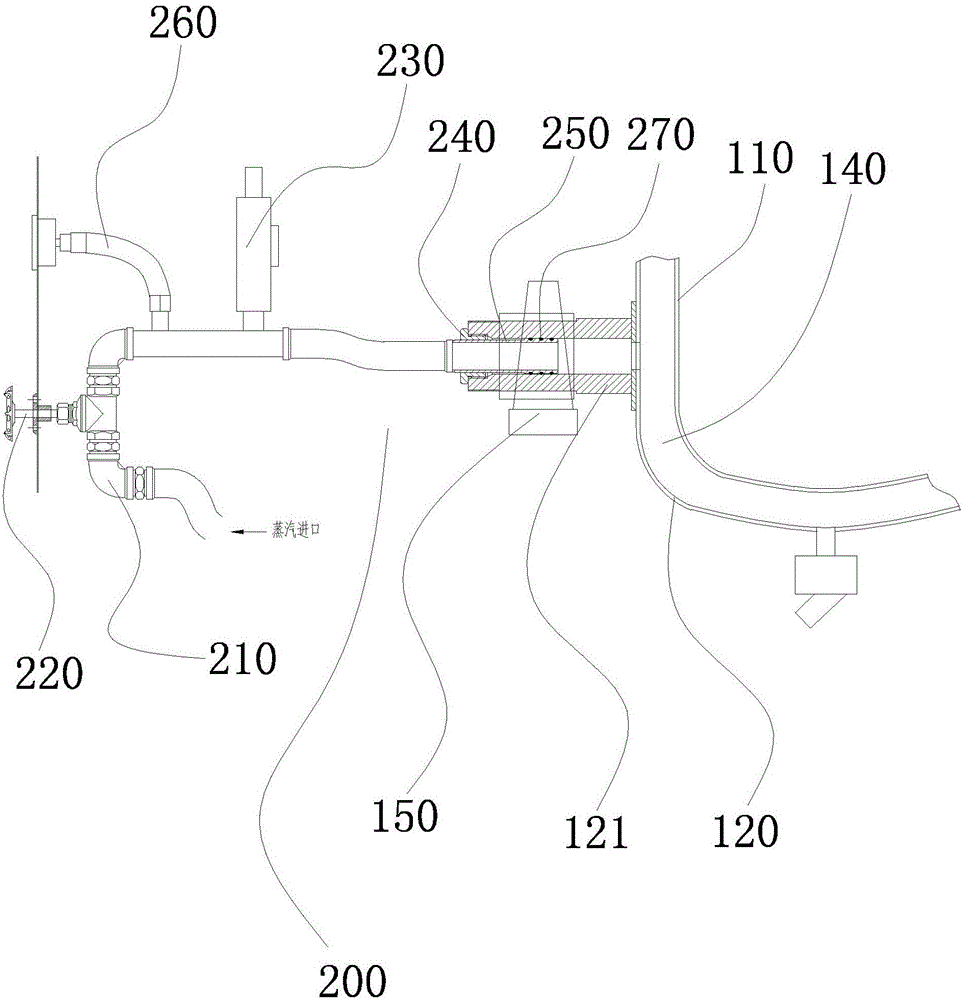

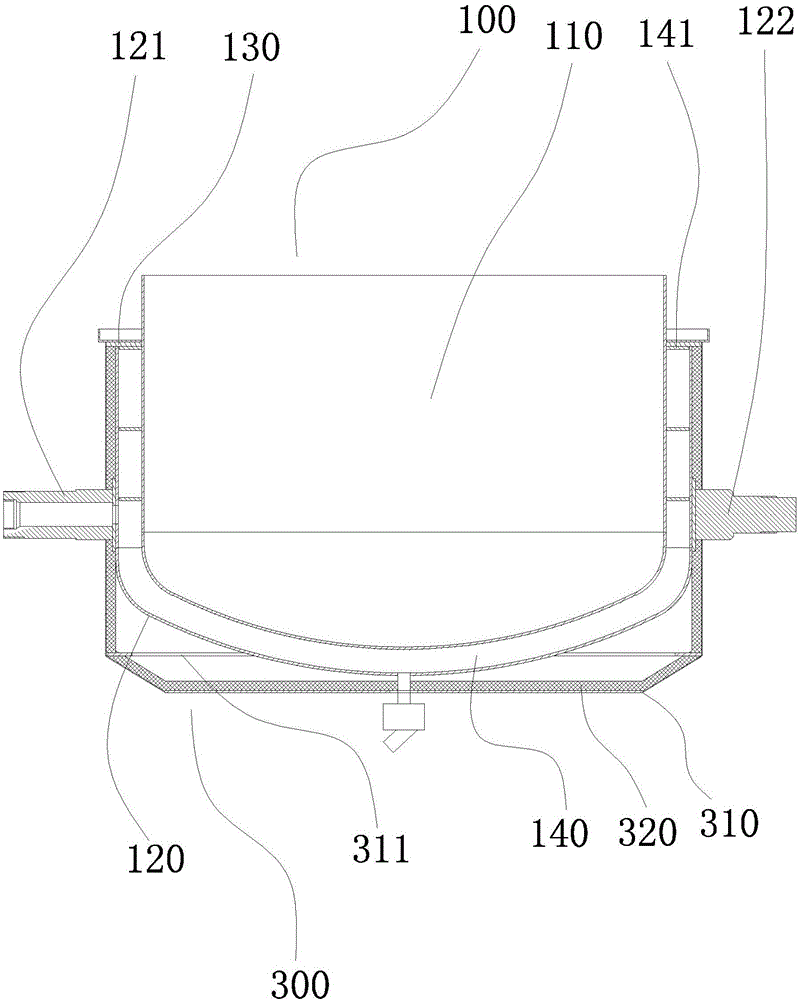

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention can be realized through the following technical solutions. A steam jacketed pot includes a pot body structure 100, a heating structure 200 and a heat preservation structure 300, wherein the pot body structure 100 is used to hold food containers, and one side thereof A left pot shaft 121 is provided. The left pot shaft 121 is hollow and communicated with the pot body structure 100. The pot body structure 100 can rotate around the left pot shaft 121. When the ingredients in the pot body structure 100 are heated Finally, the pot body structure 100 is rotated around the left pot shaft 121 at a certain angle, so that the ingredients ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com