Coir mattress making method

A brown mattress and brown rope technology, applied in mattresses, spring mattresses, other seating furniture, etc., can solve problems such as deformation, brown mattresses are easy to take off, loose, etc., and achieve firm structure, tight structure, and connection. solid effect

Inactive Publication Date: 2016-07-27

贵州娄山山棕制品有限公司

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention aims at the technical problem that the above-mentioned palm mattress is easily detached and deformed and loose, and provides a method for preparing a palm mattress with a firm structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0022] Below in conjunction with embodiment technical solution of the present invention is further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

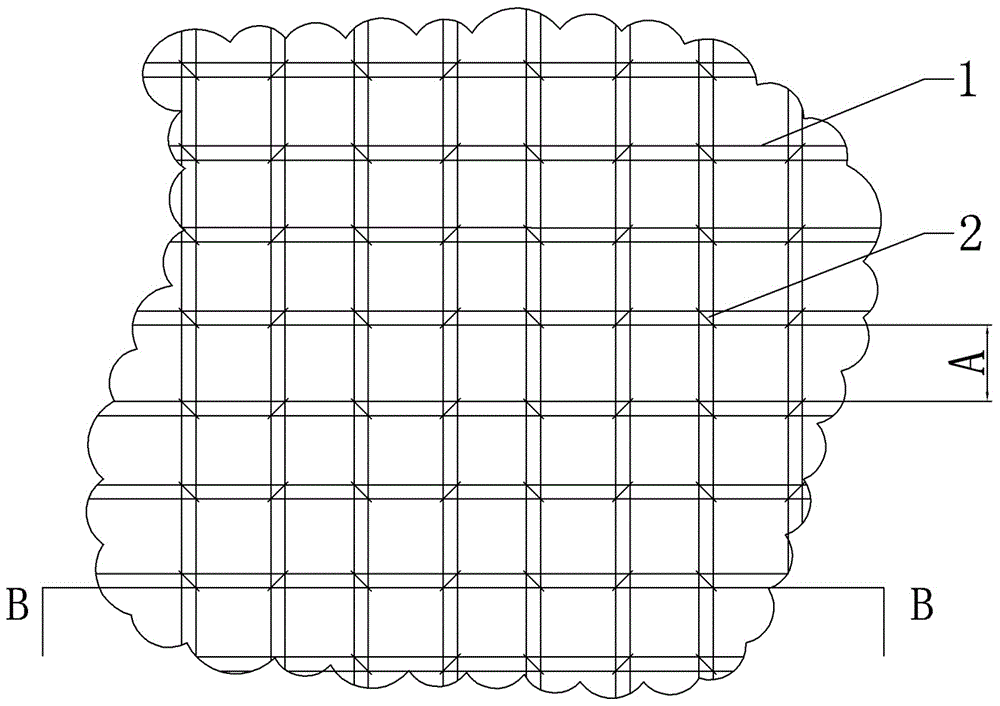

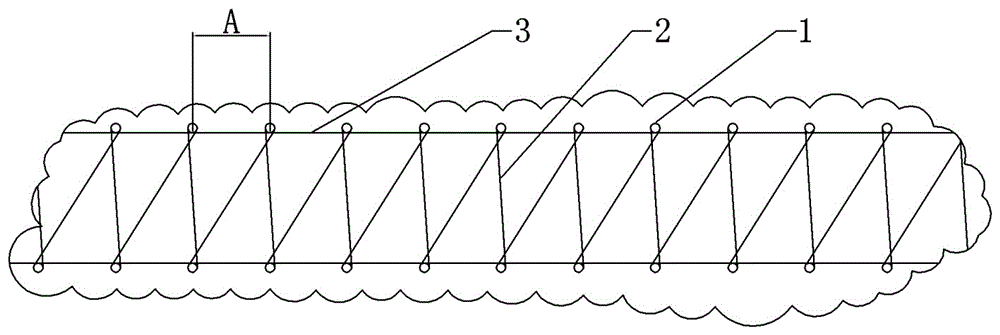

The invention discloses a coir mattress making method and belongs to the technical field of home and bedding article production.The method comprises the steps of making coir fibers; making coir ropes; distributing the coir ropes on a base plate and a press plate of a coir mattress mold in a criss-cross mode; laying the coir fibers evenly on the base plate of the coir mattress mold according to the proportion of 127-129 kg / m3; conducting sewing with every two coir ropes as stay wires intersecting into the shape of the Arabic number 8 between the upper surface and lower surface of an inner core of a coir mattress, wherein during sewing, the stay wires penetrate through the middle of the inner core of the coir mattress obliquely, and the portions, exposed from the inner core of the coir mattress, of the stay wires intersect with crossing points of the coir ropes arranged in the criss-cross mode; connecting the ends of the stay wires on the upper surface and lower surface of the inner core of the coir mattress correspondingly to the edge of the inner core of the coir mattress; conducting edge covering on the inner core of the coir mattress by means of coir fabric.The coir mattress made with the method has the advantages that the probability of fiber disengagement, deformation and looseness is reduced, and comfort level and environment friendliness are improved due to the fact that the coir mattress is not prone to deformation.

Description

technical field [0001] The invention relates to the technical field of production of household bedding, in particular to a method for preparing a palm mattress. Background technique [0002] The mountain palm mattress is made of the palm slices of the plant mountain palm. The process includes sewing the inner core of the mattress, shaping and sewing around the mattress, that is, the edge of the mattress. The sewing method of the inner core of the mattress is: after soaking the mountain palm slices in clear water, use the silk grabbing machine to grab the brown silk, select the complete and uniform brown silk, and after drying, drying, dust removal and sterilization, it is made into brown silk. Rope, evenly distribute brown rope on the bottom plate and pressing plate of the mold, then select high-quality brown silk and put it into the mold, press the brown silk to the required thickness, use the brown rope that is evenly distributed on the bottom plate and pressing plate in a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A47C23/15

CPCA47C23/15

Inventor 曹天泉

Owner 贵州娄山山棕制品有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com