Residual plastic film collecting and soil preparing integrated machine and using method thereof

A kind of residual film recovery and integrated machine technology, which is applied in the direction of soil preparation machinery, collectors, applications, etc., can solve the problems of plastic film dispersion, low cleaning rate, low operation efficiency and recovery rate, etc., and meet the needs of soil plowing , Solve the problem of plastic film recycling and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

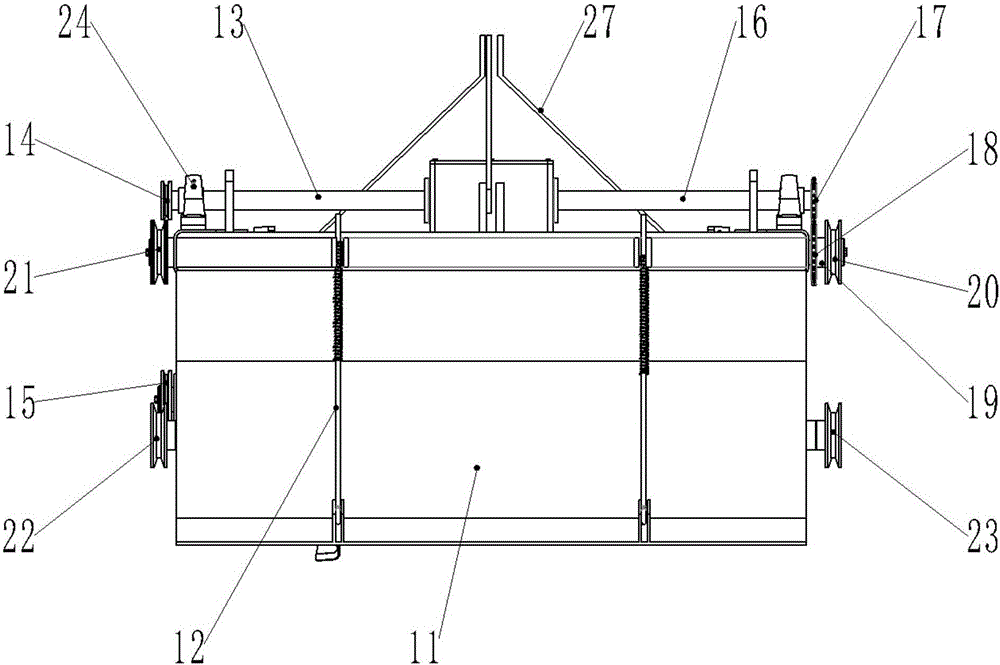

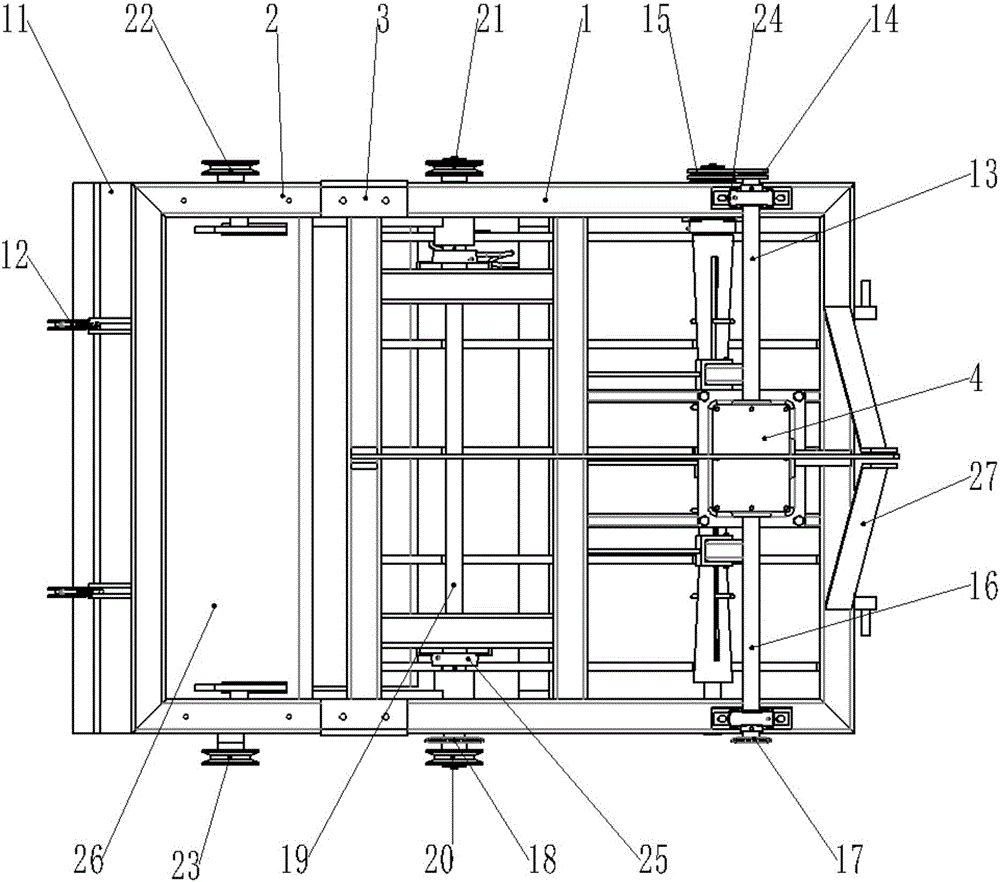

[0032] Embodiment 1: as Figure 1 to Figure 6As shown, a residual film recovery all-in-one machine includes a first support 1, on which a suspension frame 27 is fixed, and the first support 1 is connected to one end of the second support 2 through a connecting card 3, so that the film One end of the shovel 7 is hinged with the connecting card 3, and the film shovel support frame 8 is provided on the first support 1, and the middle part of the film shovel 7 is supported by the film shovel support frame 8; The film rolling drum assembly 6 is provided on the support 1; the film holding teeth 9 are also provided on the film lifting shovel support frame 8; the adjustable rotary tillage assembly 10 is provided on the first support 1 close to the connecting card 3; the second support 2 The other end is provided with a flat device. Also includes a gearbox 4, the gearbox 4 is arranged on the first bracket 1, the gearbox 4 is provided with a gearbox first output shaft 13 and a gearbox ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com