Device for testing detonation velocity of explosive at low temperature

A thermal insulation device and explosive technology, which is applied in measuring devices, fuel oil testing, instruments, etc., can solve the problems that there is no simple and convenient method for explosive detonation velocity testing, and there is no simple and convenient method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

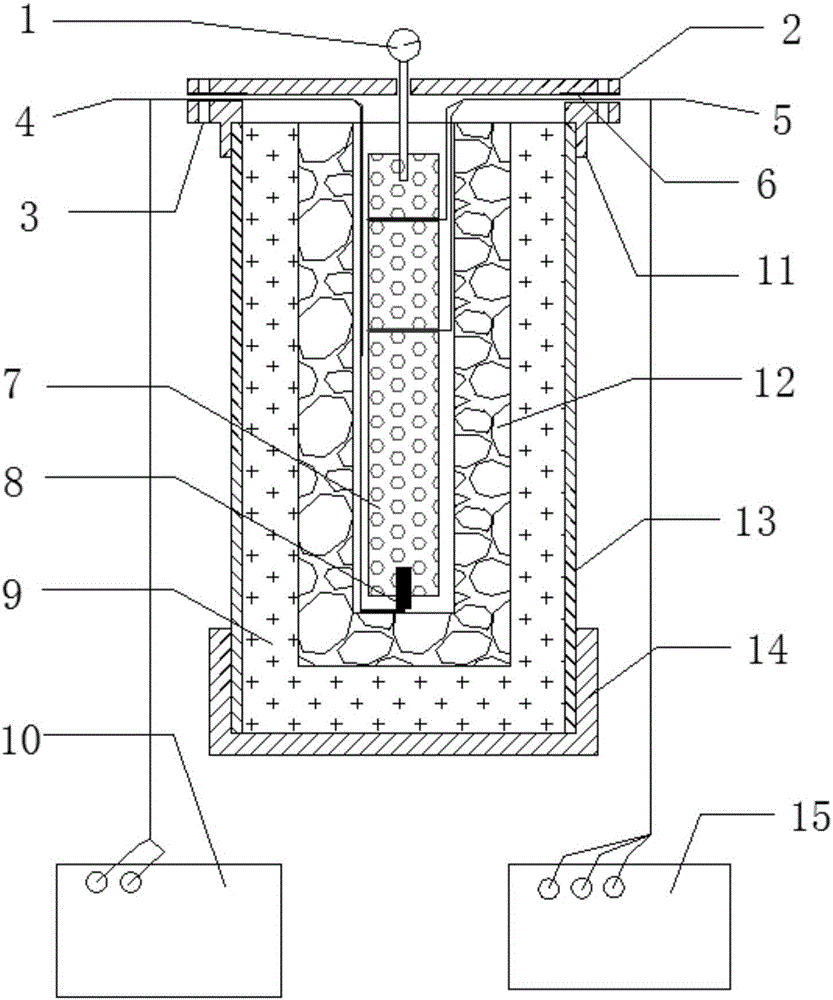

[0016] combine figure 1 As shown, a device for testing the detonation velocity of explosives at low temperatures is characterized in that it includes an explosion cavity, a freezing and heat preservation device located in the explosion cavity, and a test system. The explosion cavity has a tube body 13, and the tube body is an antistatic tube body. The lower end of the pipe body 13 is provided with a lower seal 14 for closing the lower end of the pipe body 13, and the upper end of the pipe body is provided with an upper seal upper flange 2 and a lower seal lower flange 11 for closing the upper end of the pipe body, and an upper seal upper flange 2 It is connected with the lower flange 11 of the lower seal through the screw hole 3 of the sealing flange to ensure that the device can be airtight and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com