Method and instrument for estimating welding performance of steel containing titanium and niobium elements and application of method

A welding performance and element technology, applied in the field of high-strength steel, can solve problems such as wrong design direction, misjudgment of joint hardness and strength, and reduced bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

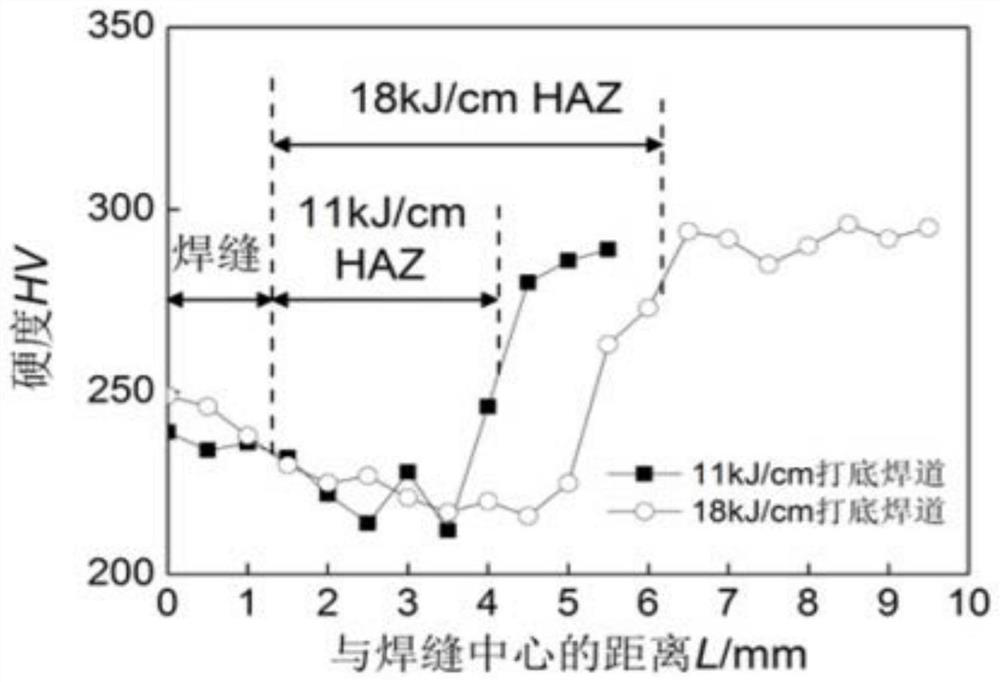

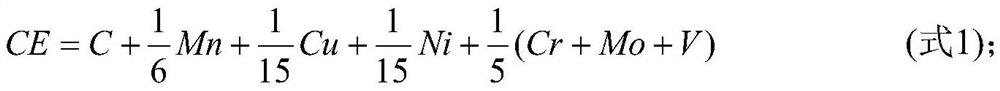

[0053]Example 1: Q700 steel plate, the chemical composition is shown in Table 1, CE=0.386 calculated with (Equation 1), Ceq=0.394 calculated with (Equation 2), P calculated with (Equation 3)cm = 0.162. Substituting Kihara formula (Equation 4) to get Hmax(Formula 4) =302HV.

[0054]Table 1 Test Q700 steel plate chemical composition (Wt%)

[0055] Steel / specification CSi Mn PSMo Ti NB Q700 / 7MM 0.0620.0561.810.0120.0040.110.100.071

[0056]In fact, the highest hardness of the welding heat-affected zone is only 232HV~271HV (Table 2), and the predicted value deviates greatly from the actual value.

[0057]Table 2 Q700 hot influencing area maximum hardness test

[0058]

[0059]CEQs = 0.328 ~ 0.352, CEQS = 0.338 ~ 0.36, P cm S = 0.158 ~ 0.159. Get into the wooden formula (formula 4) to get hmax(Formula 4) = 265HV ~ 280HV, with a higher degree of anastomosis with the measured value.

Embodiment 2

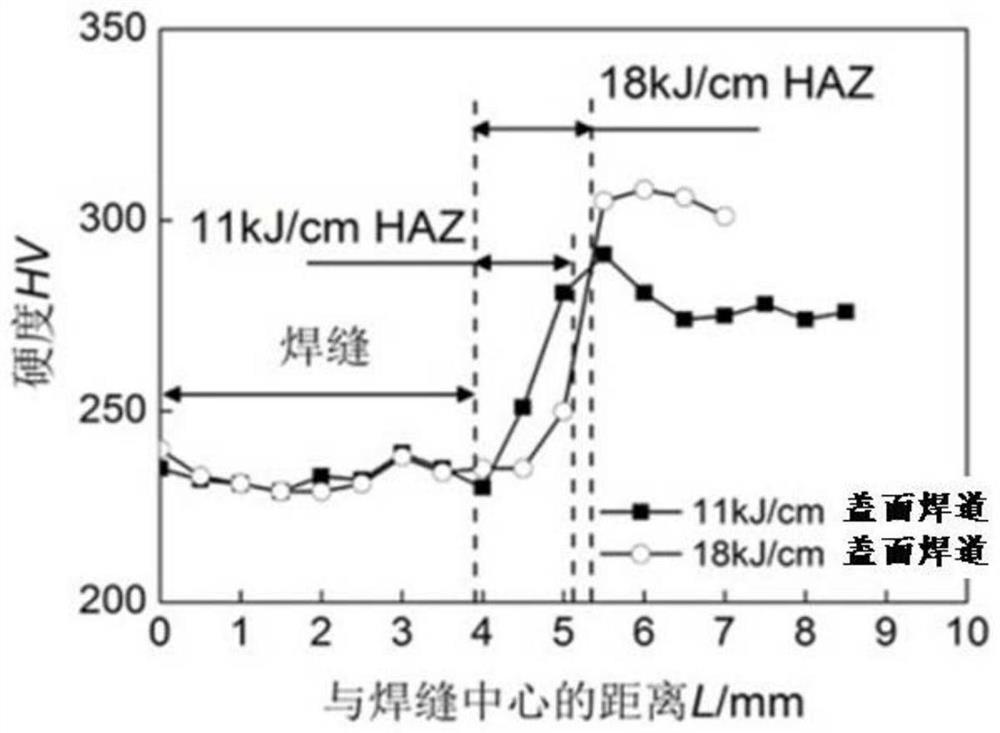

[0060]Example 2: Q600 Steel plate, chemical composition is shown in Table 3, calculated by (formula 1), calculated by (formula 2) to obtain CEQ = 0.332, calculated using (formula 3) to obtain Pcm = 0.153. Get into the wooden formula (formula 4) to get hmax(Formula 4) = 261HV.

[0061]Table 3 Test steel plate Q600 chemical composition (wt%)

[0062] Steel / specification CSi Mn PSTi NB Q600 / 10mm 0.070.211.520.0120.0030.1190.046

[0063]In fact, the highest hardness of the welded heat affected area is only 217 hV ~ 230HV (Table 4), and the predicted value is large.

[0064]Table 4 Q600 maximum hardness test parameters and results

[0065]

[0066]CEQs = 0.269 ~ 0.29, CEQS = 0.278 ~ 0.299, P, 5.278 ~ 0.299, Pcm S = 0.149 ~ 0.151. Get into the wooden formula (formula 4) to get hmax(Formula 4) = 225 ~ 239, with a higher degree of anastomosis with the measured value.

Embodiment 3

[0067]Example 3: Q550D, Q690D Steel plate, chemical composition is shown in Table 3, Q550D Calculated CE = 0.434, calculated by (formula 2), calculated using (formula 3) to calculate Pcm = 0.19. Get into the wooden formula (formula 4) to get hmax(Formula 4) = 326 hV. The Q690D was calculated using (formula 1) to obtain CE = 0.454 with (Equation 2), calculated using (formula 3) to obtain Pcm = 0.208. Get into the wooden formula (formula 4) to get hmax(Formula 4) = 342HV.

[0068]Table 5 Test Steel Q550D, Q690D Chemical Components (WT%)

[0069] Steel / specification CSi Mn PSNi Mo CrCu BTi NB Q550D / 30mm 0.0630.311.500.0070.0020.160.170.290.27--0.0120.046 Q690D / 30mm0.060.291.670.0090.00290.240.190.250.380.00130.0170.054

[0070]In fact, the highest hardness of Q550D welding heat affected zone is only 233HV ~ 276HV (Table 6), and the highest hardness of the Q690D welded heat affected zone is 312HV ~ 348HV (Table 7), and the predicted value has a certain deviation of the actual value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com