Environmental aging simulation test method for sizing material

A technology for simulating testing and sizing, which is applied in measuring devices, analytical materials, instruments, etc., can solve the problems of high price and long testing time, and achieve the effect of simple method, good correlation and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention provides a rubber environment aging simulation test method, the steps are as follows:

[0021] 1) vulcanize the rubber material, the method of the present invention can simulate the environmental aging of different formula rubber materials; and the film after vulcanization can be cut according to different test items (such as dumbbell-shaped samples, rectangular samples);

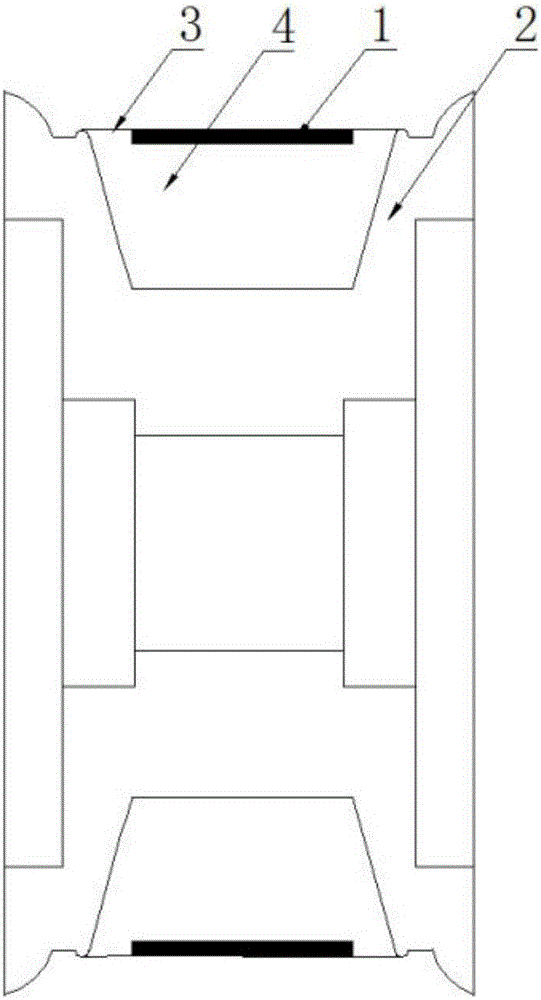

[0022] 2) Bond the cut film to the center of the groove of the rim, and distribute the sample intervals evenly on the rim; and each film cannot be in contact with the rim, and the interval between each film is 50mm;

[0023] 3) Install the tire matching the rim size to obtain the tire, rim and film assembly;

[0024] 4) Pour compressed air into the tire, put the assembled tire in the water tank for at least 30 minutes, check whether there is air leakage at the bead and valve, if there is no air leakage, park it at ambient temperature for more than 24 hours, put the tire inside The comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com