Torque test system and method of car seat belt coil spring based on labview

A technology for torque testing and seat belts, applied in the field of LabVIEW-based automotive seat belt coil spring torque testing systems, can solve problems such as the inability to meet the daily production requirements of the factory, the inability to guarantee the measurement results, and the poor measurement accuracy, and to achieve high test efficiency. , the effect of high measurement accuracy and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

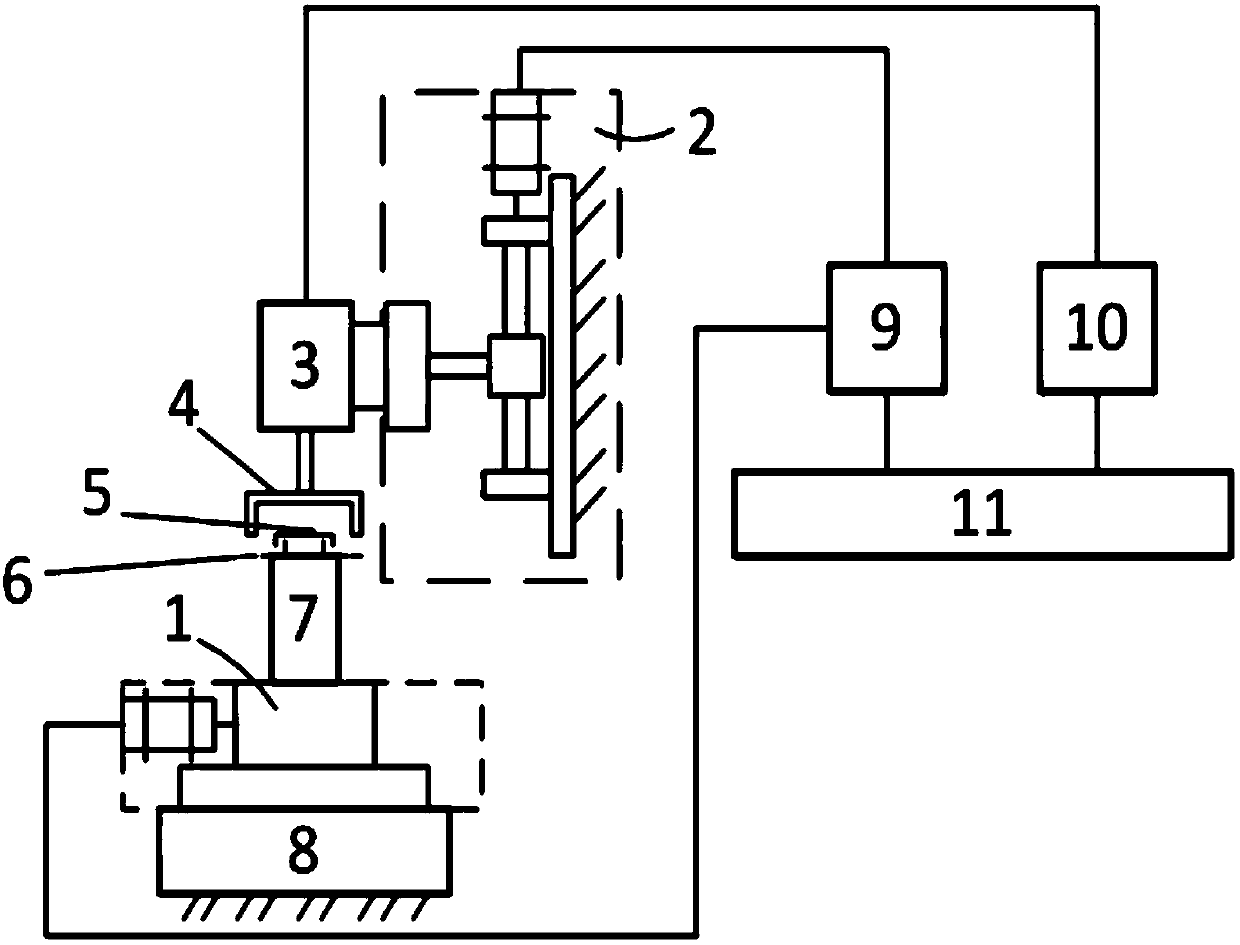

[0027] combine figure 1 As shown, a kind of automobile seat belt coil spring torque test system based on LabVIEW of the present embodiment comprises a precision electric control turntable 1, and the precision electric control turntable 1 is installed on the position fine-tuning mechanism 8, and in the precision electric control turntable 1 A reel 7 is installed at the center of the rotating disk; a mounting disc 6 for installing the coil spring 5 is set on the reel 7, one end of the coil spring 5 is fixedly connected to the reel 7, and the other end of the coil spring 5 is fixedly connected to the mounting disc 6; The top of reel 7 is provided with the precision torque sensor 3 that vertical direction places, and the axis of reel 7 coincides with the center line of precision torque sensor 3; connected; the lower end of the precision torque sensor 3 is connected to the jaw 4 for clamping the mounting plate 6 through a coupling; the output end of the precision torque sensor 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com