A measuring device for the axial force of a rotating shaft

A technology for measuring devices and rotating shafts, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., which can solve the problem of difficulty in ensuring accuracy, easy axial play, and preloading of the bearing outer ring and the mounting seat. Force is difficult to control and other problems, to achieve the effect of stable and reliable signal and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described below.

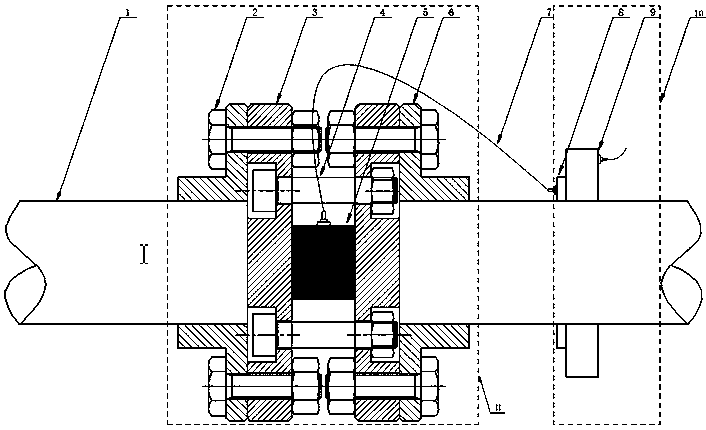

[0018] Implementation of the present invention provides a rotating shaft axial force measuring device, the measuring device includes a rotating shaft 1, a sensor unit 11 and a signal line 7; its composition is that the sensor unit 11 is sleeved and fixed on the corresponding The shaft 1 is connected to the corresponding slip ring 10 sleeved on the rotating shaft 1 through the signal line 7 on the corresponding unidirectional pressure sensor 5 .

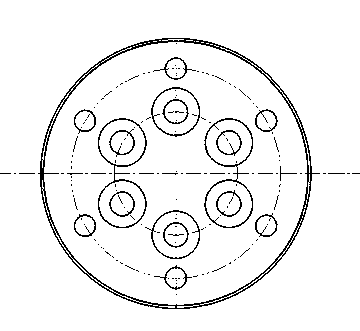

[0019] The above-mentioned sensor unit 11 is clamped and fixed by two corresponding connecting discs 3 with a one-way pressure sensor 5 that is in close contact with the surface of the rotating shaft 1, and is clamped by two corresponding couplings 6 again. It is composed of two corresponding connecting discs 3 fixed; the rotating shaft 1 outputs the axial force of the rotating shaft to the slip ring 10 through the unidirectional for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com