Lens detecting system

A detection system and lens technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of low detection efficiency and cumbersome operation, and achieve the effects of improving detection time, saving labor costs, and efficient and stable detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

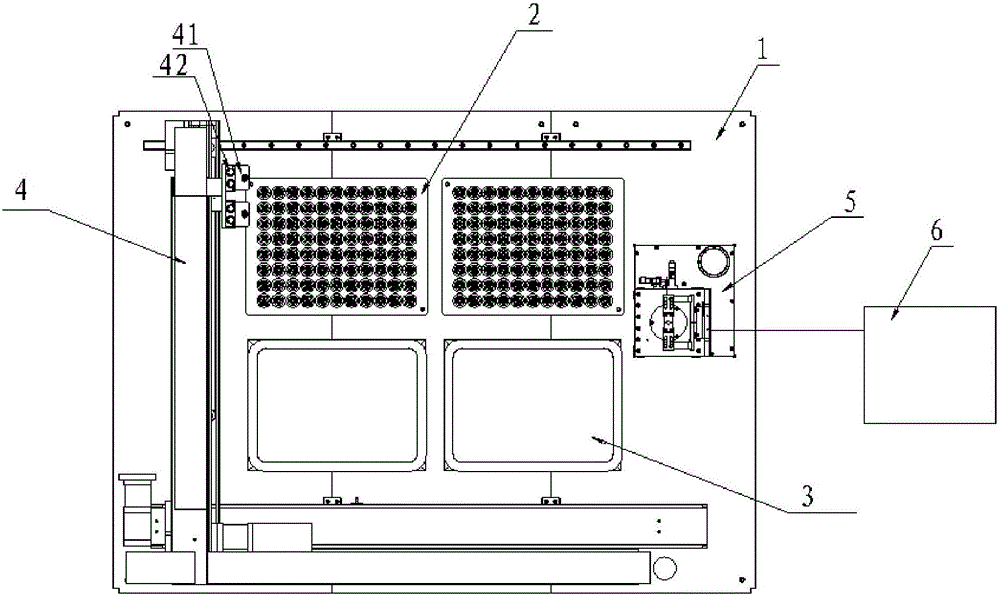

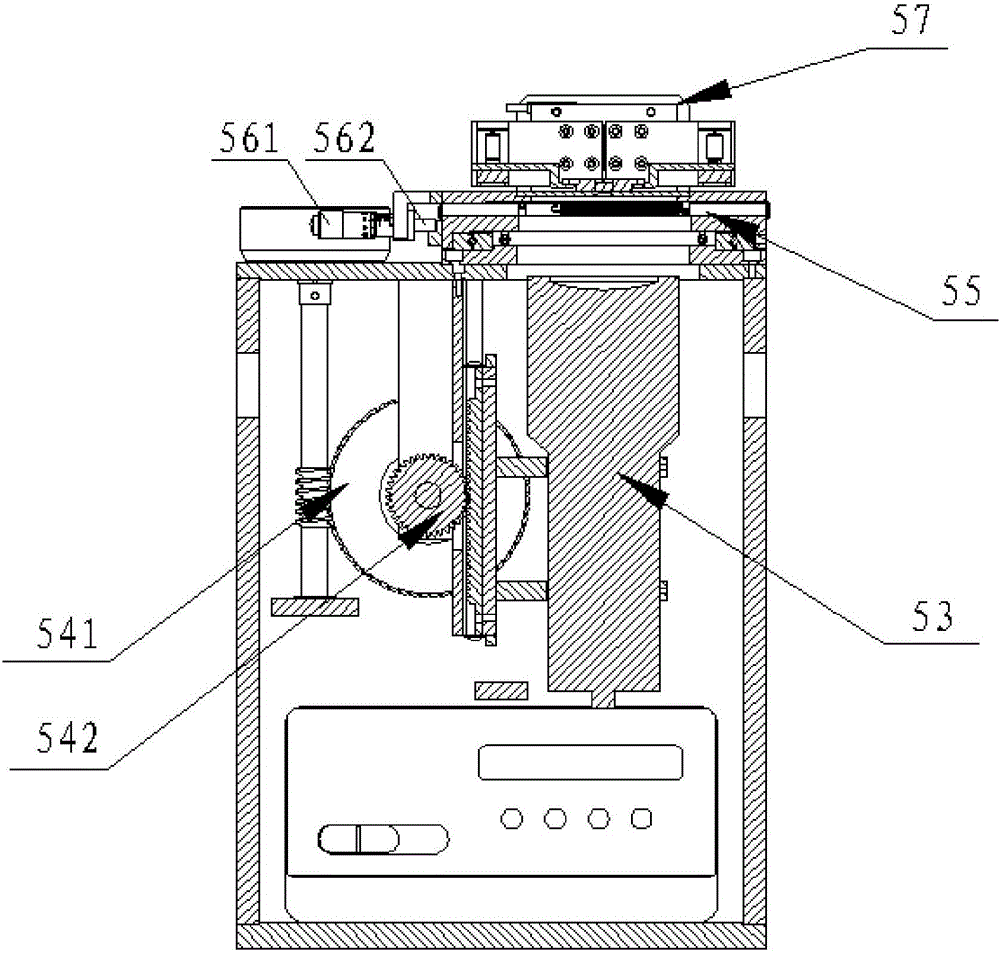

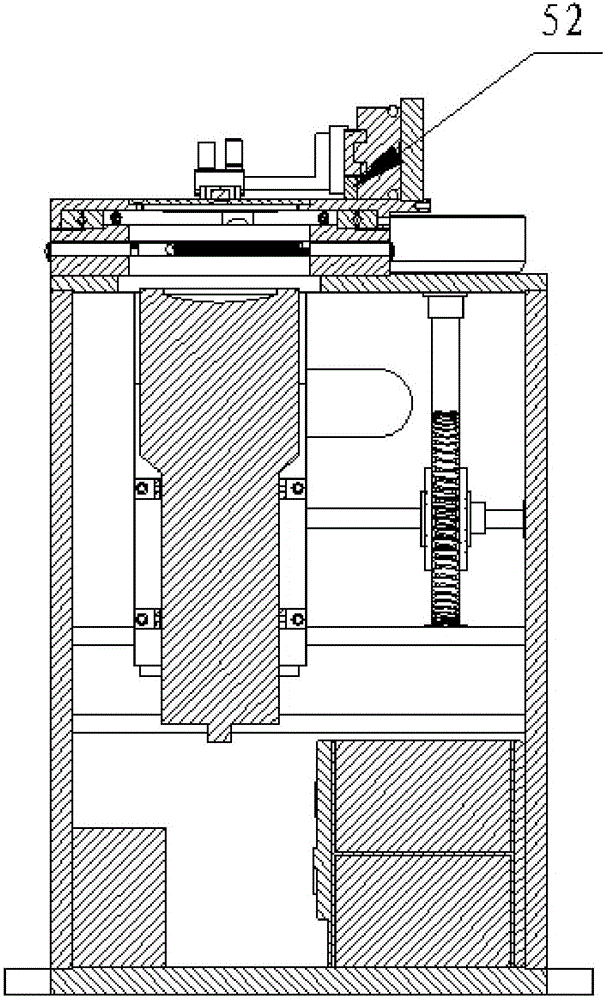

[0019] Such as figure 1 , 2 , 3, the lens detection system includes a base 1, the base 1 is provided with an inspection area 2, a discharge area 3, a manipulator 4, a detection device 5 and a client terminal 6, the detection device 5 is connected to the client terminal 6, and the detection device 5 includes a sensor 51 and a grating 52, and the client terminal 6 is a computer. The manipulator 4 is used to automatically take the lens to be inspected in the area 2 to be inspected, and place it on the detection device 5. The grating 52 of the detection device 5 passes through the detection of lens displacement, and a vernier caliper is attached to detect the outer diameter of the lens. The sensor 51 detects the center thickness and depth of the lens. After the detection is completed, the manipulator 4 moves the lens to the discharge area 3, and the data detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com