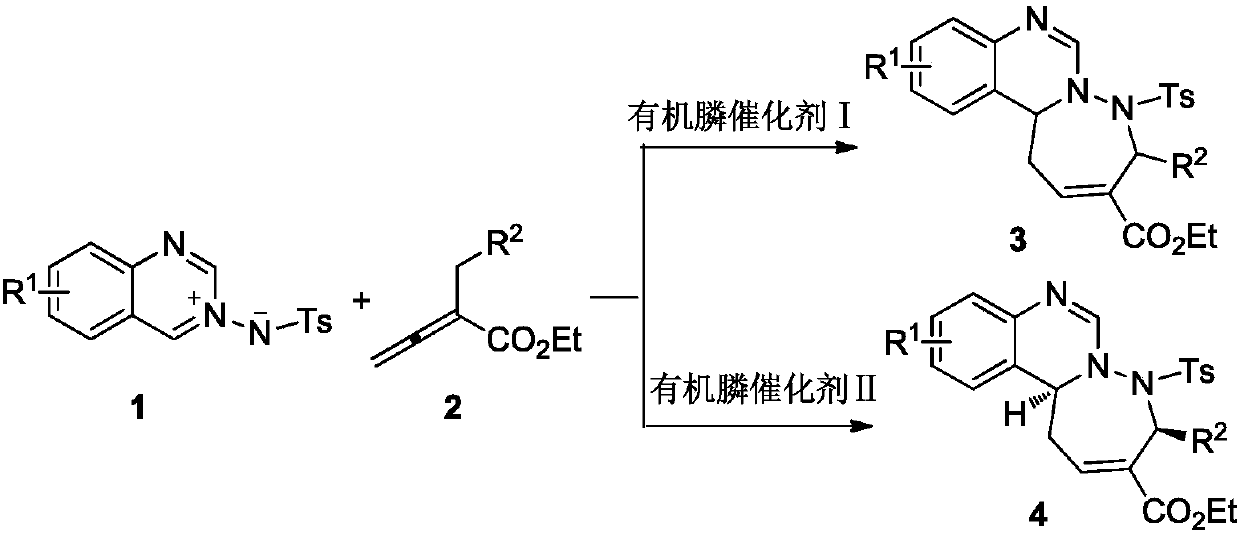

Tetrahydrodiazepine and quinazoline compounds and preparation method thereof

A compound and quinoline technology, applied in the field of heterocyclic quinoline compounds and their preparation, to achieve the effects of high diastereoselectivity and enantioselectivity, mild reaction conditions and few side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

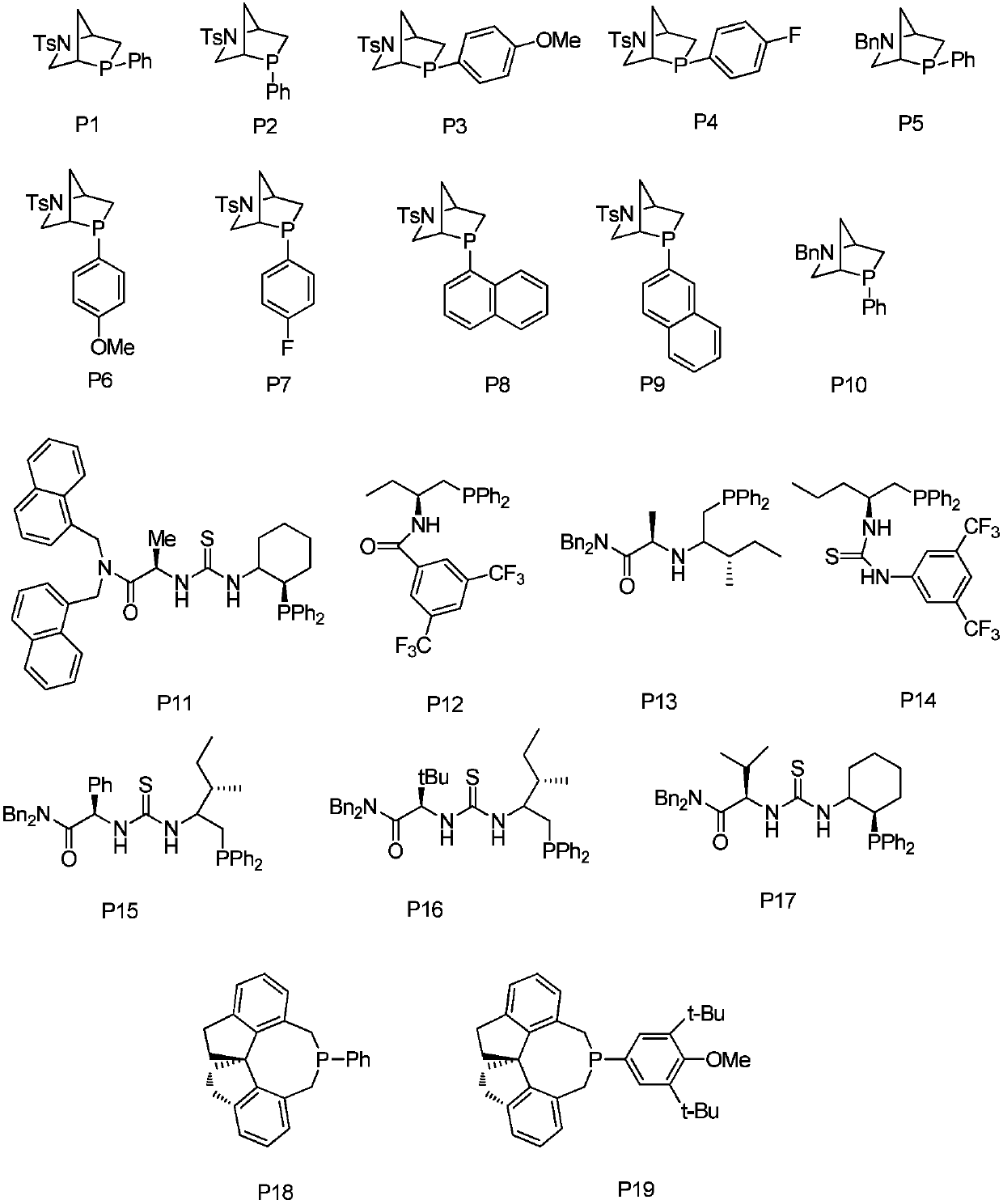

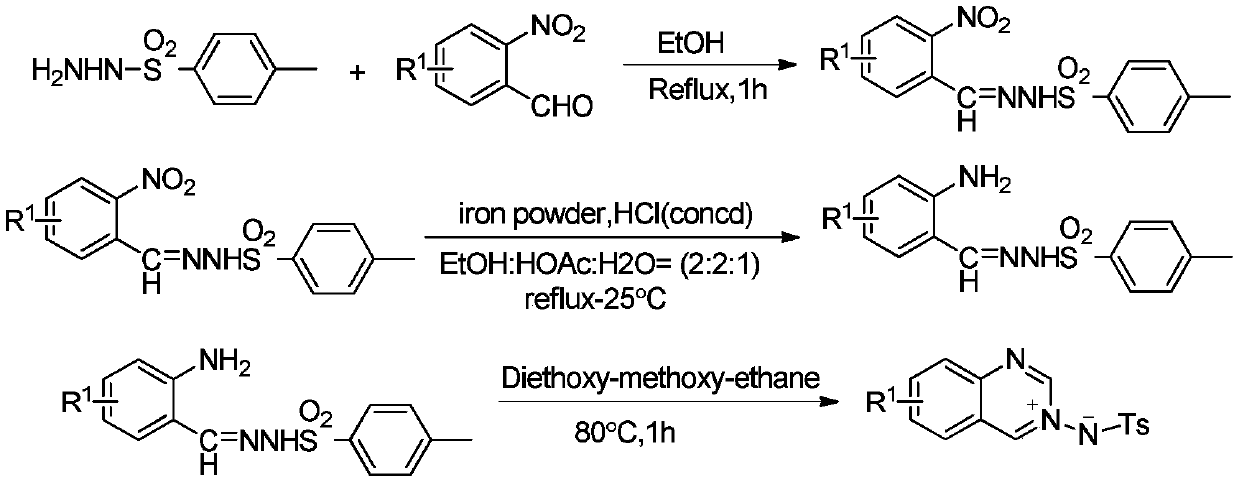

Method used

Image

Examples

Embodiment 1

[0027]

[0028] Put 0.0374g (0.125mmol) of compound 1a, 0.0384g (0.190mmol) of compound 2a and 2mL of dichloromethane into a dry 15mL Shrek tube, add 6.6mg (0.025mmol) of triphenylphosphine and mix well for cycloaddition into a reaction. In this reaction system, the molar ratio of compound 1a to compound 2a is 1: 1.5, and organophosphorus catalyst I accounts for 20% of the molar percentage of compound 1a, stirs at 25 ℃ for 6 hours, and concentrates through the column with rotary evaporator (acetic acid Ethyl ester:petroleum ether=1:4, v / v), to obtain 50.0 mg of product 3aa, with a yield of 80%.

Embodiment 2

[0030]

[0031] Put 0.0374g (0.125mmol) of compound 1a, 0.0384g (0.190mmol) of compound 2a and 2mL of dichloromethane into a dry 15mL Shrek tube, add 0.025mmol of trimethylphosphine and mix well for cycloaddition reaction. In this reaction system, the molar ratio of compound 1a to compound 2a is 1: 1.5, and organophosphorus catalyst I accounts for 20% of the molar percentage of compound 1a, stirs at 25 ℃ for 6 hours, and concentrates through the column with rotary evaporator (acetic acid Ethyl ester:petroleum ether=1:4, v / v), to obtain 21.9mg of product 3aa, yield 35%.

Embodiment 3

[0033]

[0034] Put 0.0374g (0.125mmol) of compound 1a, 0.0384g (0.190mmol) of compound 2a and 2mL of dichloromethane into a dry 15mL Shrek tube, add 0.025mmol of tributylphosphine and mix well for cycloaddition reaction. In this reaction system, the molar ratio of compound 1a to compound 2a is 1: 1.5, and organophosphorus catalyst I accounts for 20% of the molar percentage of compound 1a, stirs at 25 ℃ for 3 hours, and concentrates through the column with rotary evaporator (acetic acid Ethyl ester:petroleum ether=1:4, v / v), to obtain 25.0mg of product 3aa, yield 40%.

[0035] It can be seen that the effect is very excellent when triphenylphosphine is selected as the catalyst.

[0036] 3aa NMR

[0037]1 H NMR (300MHz, CDCl 3 )δ7.85-7.72 (m, 2H), 7.43 (dd, J = 9.1, 3.4Hz, 1H), 7.37-7.26 (m, 7H), 7.17 (td, J = 7.6, 1.5Hz, 1H), 7.06 (td, J=7.5, 1.4Hz, 1H), 7.00 (dd, J=7.8, 1.3Hz, 1H), 6.89(s, 1H), 6.80 (dd, J=7.6, 1.5Hz, 1H), 6.05( d, J=0.8 Hz, 1H), 4.92(d, J=10.3Hz, 1H), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com