Reinforcing bar bundling machine based on driven opening and closing clamping block devices

A strapping machine and clamping block technology, applied in packaging, strapping materials, strapping machine parts, etc., can solve the problems of complex structure of opening and closing conduits, complex control actions, and easy failures, so as to save control procedures, The effect of simplifying the motion mechanism and avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

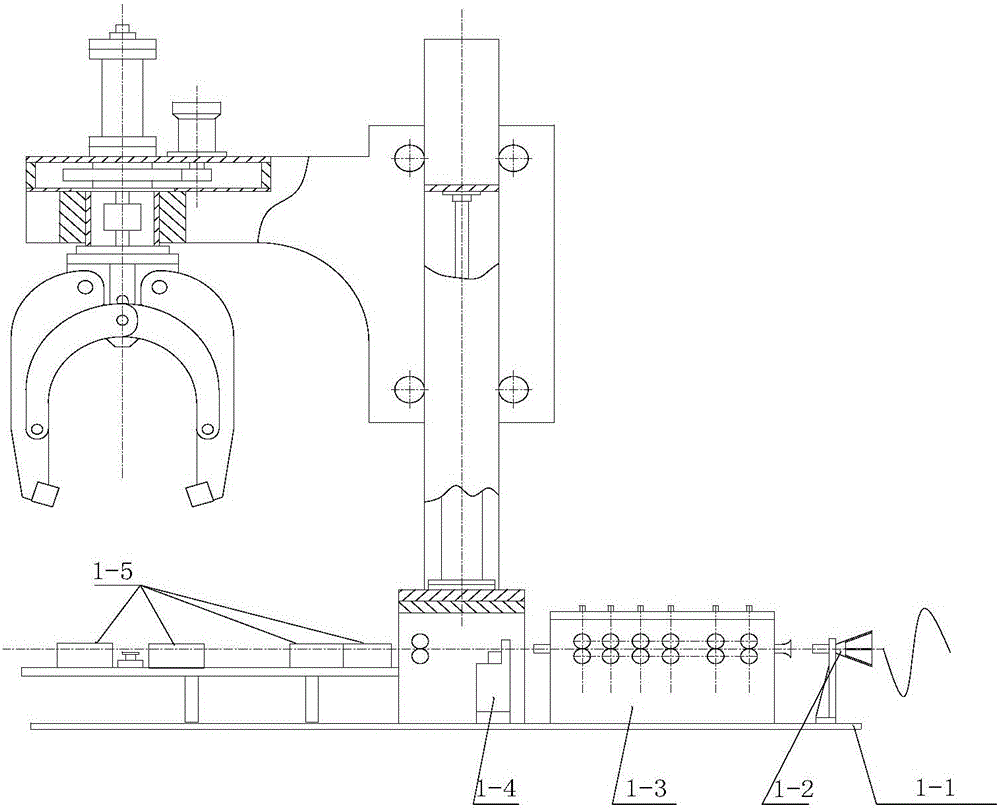

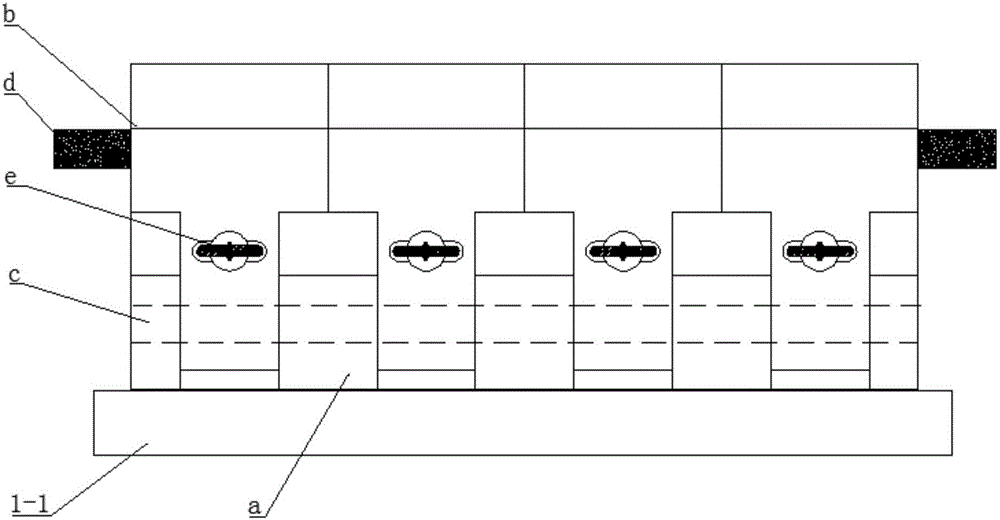

[0035] A steel bar binding machine based on a driven opening and closing clamp device, see the attached figure 1 , which includes a bottom threading straightening workbench and a rotary clamping mechanical claw. The bottom threading straightening workbench consists of a base 1-1, a random wire frame 1-2, a roller straightening machine 1-3, and a hydraulic shear 1- 4. The driven opening and closing clamping device 1-5 is composed of a column, and the random wire frame, roller leveler, hydraulic shear, and driven opening and closing clamping device are fixed on the base in sequence from right to left. The column is vertically fixed on the base; the rotary clamping mechanical claw is arranged on the column so that it can move up and down through the bracket. The overall structure of the steel bar binding machine based on the driven opening and closi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com