Automatic lipstick tube assembling device

An automatic assembly, lipstick tube technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., to achieve high positioning accuracy, ample space, and small equipment footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

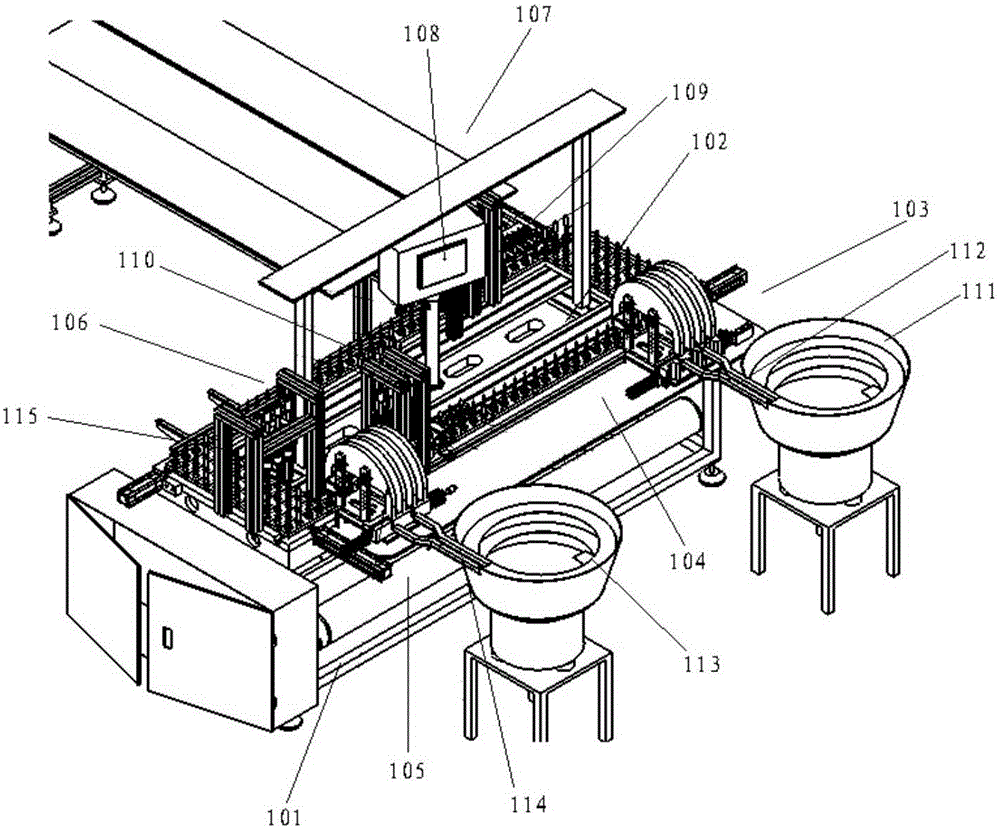

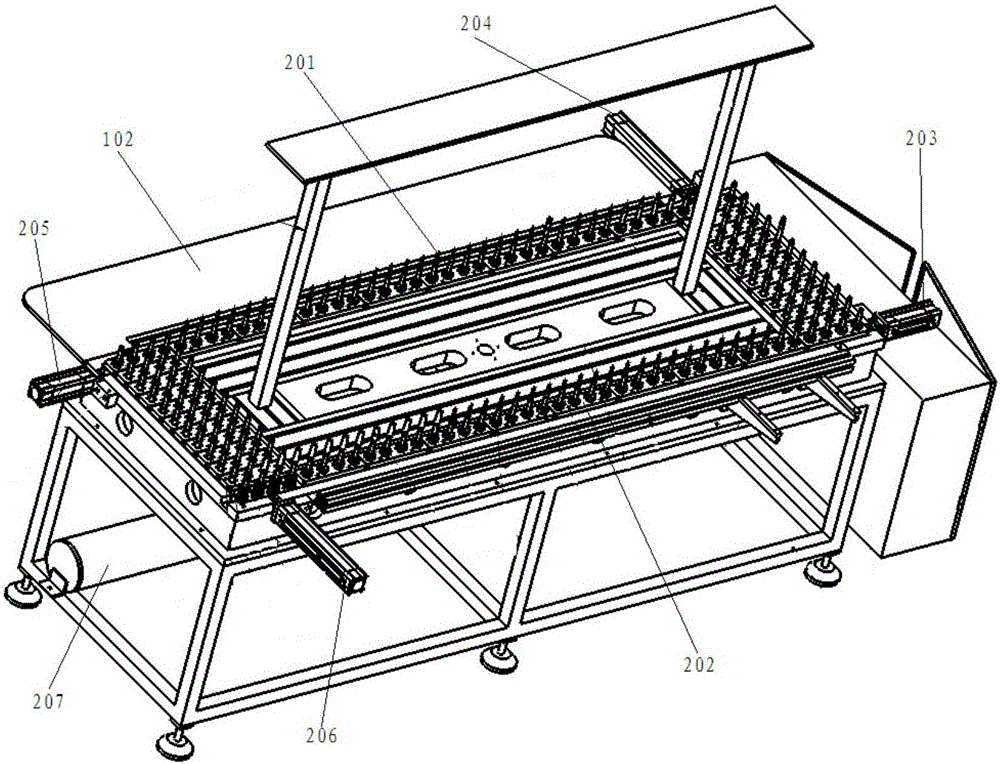

[0048] Such as figure 1 and figure 2 The shown lipstick tube automatic assembly equipment includes a frame 101, the table 102 of the frame 101 is provided with an annular guide rail groove 201, and the guide rail groove 201 is filled with a jig plate 202, and the jig plate 202 is placed on the cylinder 204, cylinder 205, Driven by the air cylinder 206 and the air cylinder 207, it circulates in the rail groove 201 .

[0049] The table top 102 is provided with the upper bead working position 103, the middle beam inserting position 104, the screw working position 105, the upper bottom working position 106 and the unloading working position 107 which are arranged in sequence along the guide rail groove 201. The jig plate 202 is pushed by the cylinder Go through the above-mentioned working positions successively.

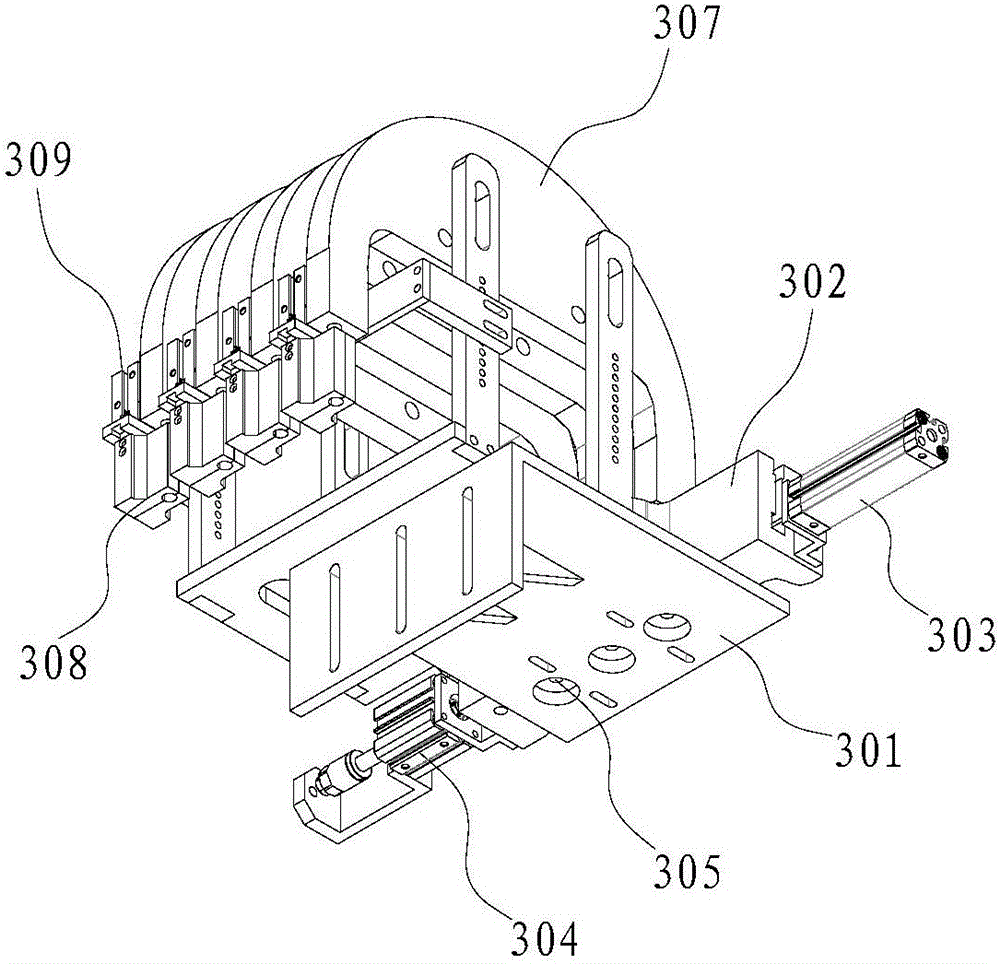

[0050] The bead loading mechanism is provided in the bead loading station 103. The bead loading mechanism has a feeding vibrating plate 111 for storing beads, and del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com