Precise self-centering chuck suitable for super-large workpieces

A self-centering chuck, super-large technology, applied in the direction of the chuck, can solve the problems of increased friction, excessive radial size, deviation, etc., to achieve high clamping and positioning precision, stable meshing rotation, The effect of ensuring positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

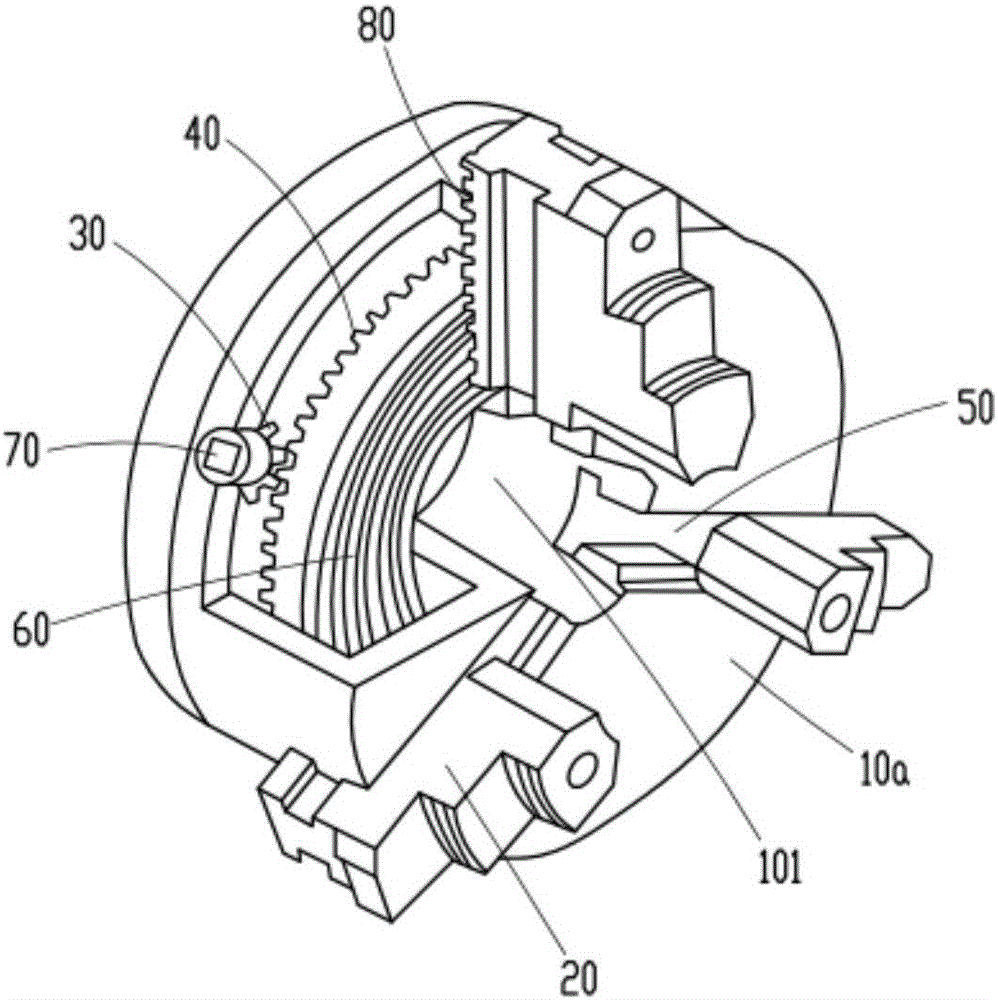

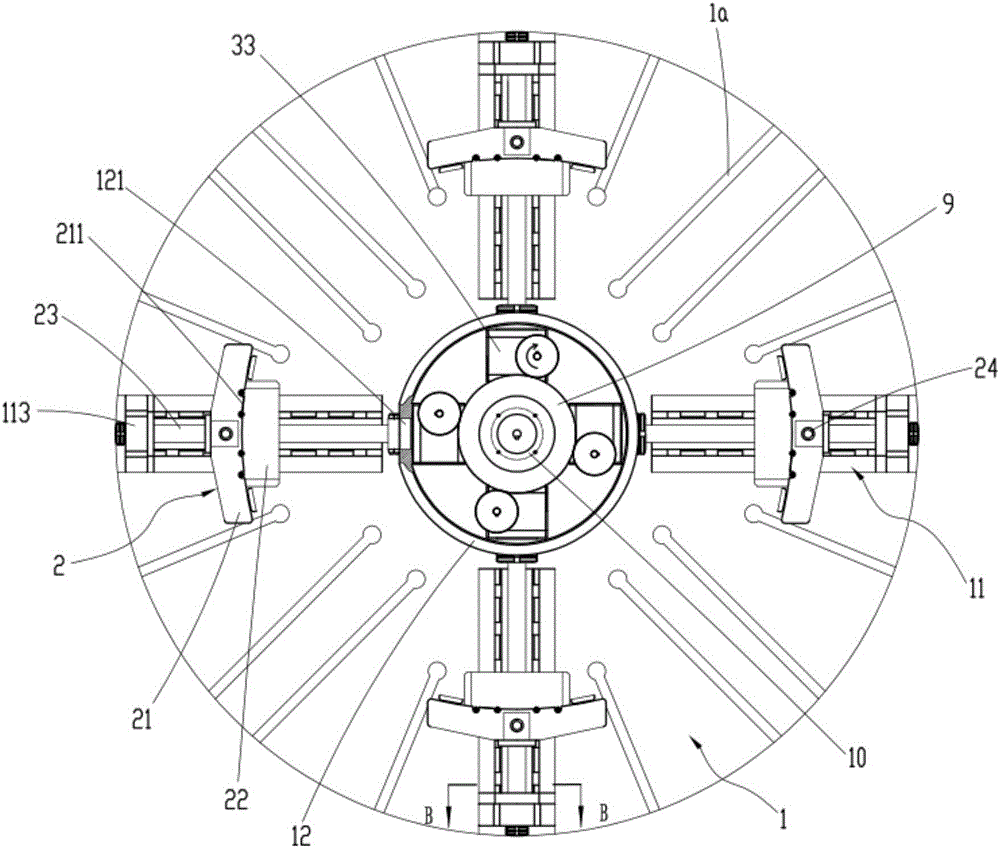

[0037] like figure 2 and image 3 As shown, the present invention provides a precision self-centering chuck suitable for extra-large workpieces, including a disc body 1 and a plurality of jaw mechanisms 2 slidably arranged on the disc body 1, and the disc body 1 is also provided with A jaw drive mechanism 3 that drives multiple jaw mechanisms 2 to clamp or loosen, the jaw drive mechanism 3 includes a numerically controlled torque motor 31, a plurality of transition gears 32, a secondary envelope reducer 33, and a first gear 34, Internal teeth 341 and external teeth 342 are respectively provided on the inner and outer circular surfaces of the first gear 34, and the numerically controlled torque motor 31 is arranged on the middle part of the disc body 1, and the motor shaft of the numerically controlled torque motor 31 is equipped with motor teeth 4, A plurality of transition gears 32 are evenly arranged between the motor teeth 4 and the first gear 34, and are all meshed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com