Solar panel automatic cleaning equipment

A solar panel and automatic cleaning technology, applied in cleaning methods and utensils, cleaning methods using tools, photovoltaic power generation, etc., can solve the problem that the shape and size of cleaning parts cannot be unified, increase design costs and production costs, and have no floor space. Make full use of problems such as making full use of ground space, which is conducive to standardization and serialization, and has the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

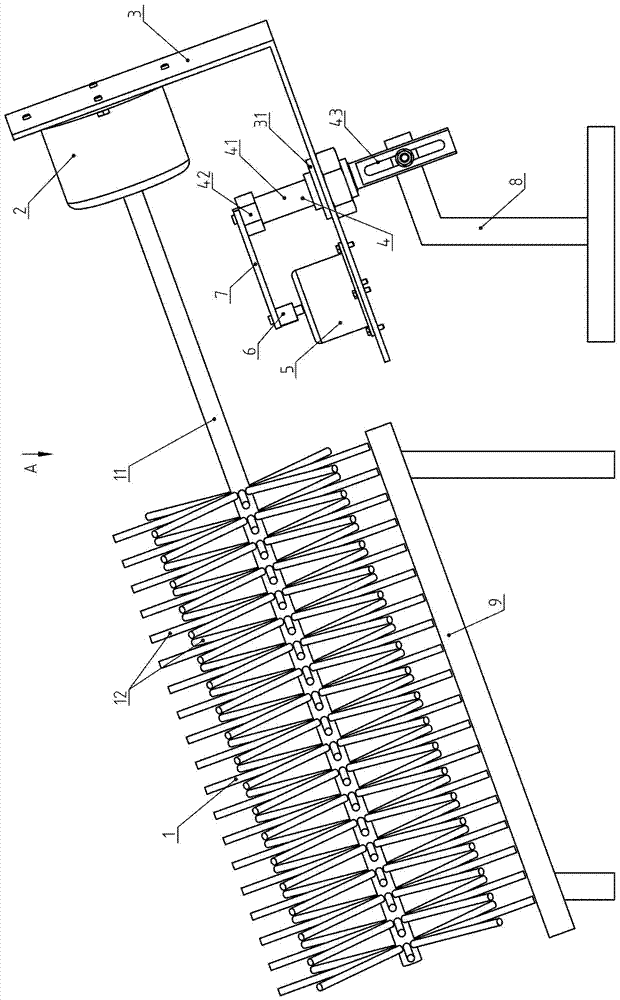

[0035] Embodiment 1: see Figure 1 to Figure 4 .

[0036] The automatic cleaning equipment of the present embodiment is the situation of configuring a single solar panel,

[0037] An automatic cleaning device for solar panels, including a brush 1, a rotating motor 2, a swing frame 3, a small crank 6, a small connecting rod 7, a base 8, a separate swing motor 5, and a rocker assembly 4,

[0038] The mounting base of the swing motor 5 is fixedly connected to the swing frame 3, the output shaft of the swing motor 5 is fixedly connected to the small crank 6, and the swing arm component 4 has a long sliding hole 43, which is connected to the swing arm component 4 and the base 8 through a threaded connector. , unscrew the threaded connector, you can adjust the relative position or angle between the two, and tighten it after adjusting properly; the swing arm assembly 4 and the swing frame 3 are connected by the swing frame hinge 31; the small crank 6 and the small connecting rod 7 ...

Embodiment 2

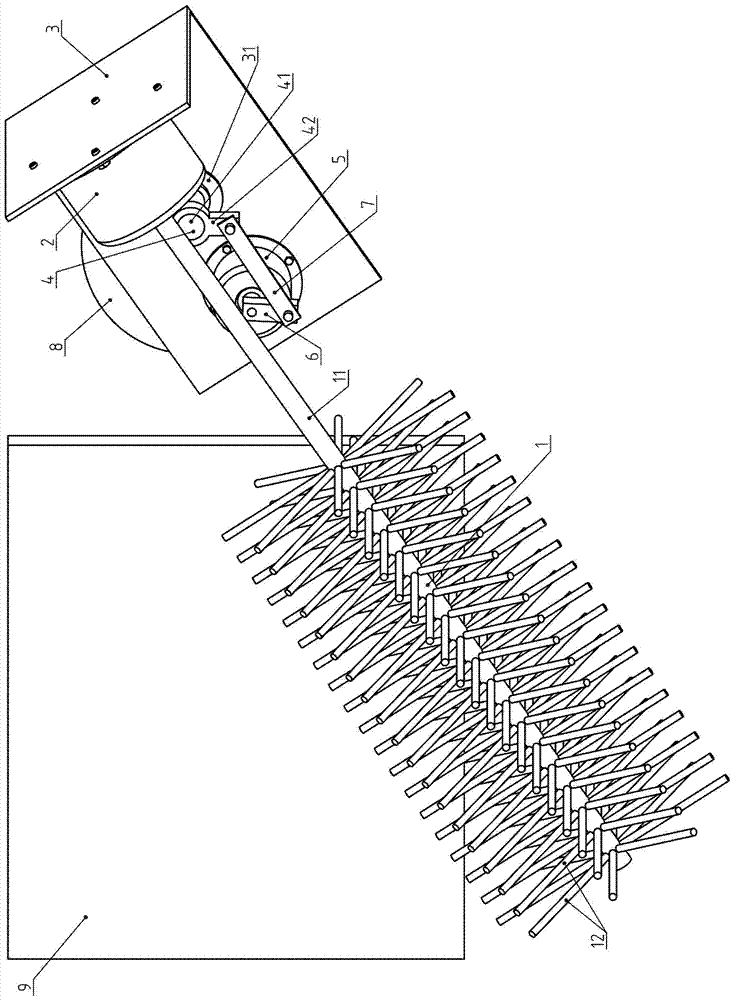

[0044] Example 2: see Figure 5 .

[0045] In this embodiment, four solar panels 9 are arranged side by side in a row, and a set of solar automatic cleaning equipment is installed on the north of each solar panel 9, and four sets are installed in total. The solar automatic cleaning equipment not only cleans a solar panel 9, but can clean two or three solar panels 9, can not protrude outside the solar panel when cleaning to any position, can improve utilization rate like this.

[0046] The solar panel is installed obliquely, the south-facing end is lower, and the north-facing end is higher. This embodiment is installed at the northern end of the solar panel 9 and does not occupy the positions on the east and west sides. There is no need to leave too much space between two side-by-side solar panels, which can make full use of the ground space and save land. One brush not only cleans one solar panel, but also cleans two or three adjacent solar panels, so the utilization rate of...

Embodiment 3

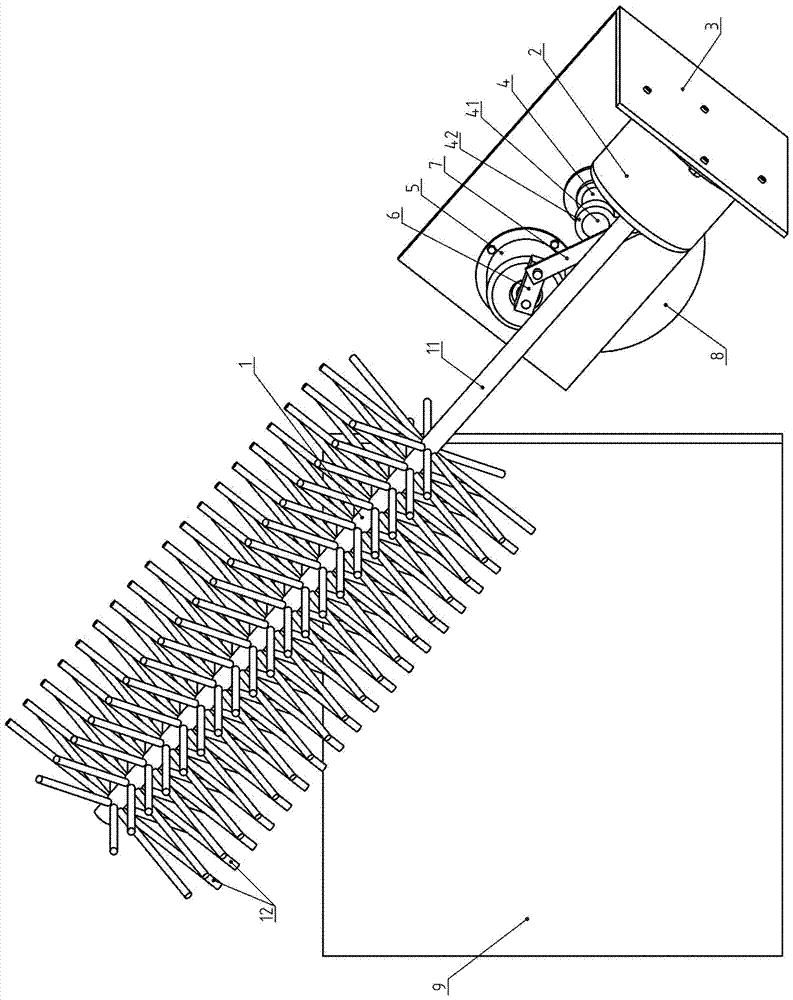

[0048] Embodiment 3: see Image 6 .

[0049] In this embodiment, a plurality of swing frames 3 are connected through a drive hinge 105 and a common connecting rod 104, the fixed flange of the common swing motor 102 is connected with the frame, the output shaft is fixedly connected with a large crank 106, and the common connecting rod 104 , big crank 106 are respectively connected with the two ends of big connecting rod 103 by hinges, big crank 106, big connecting rod 103, public connecting rod 104, rocking frame 3 form the crank linkage mechanism, when public rocking motor 102 rotates continuously, through The large connecting rod 103 and the common connecting rod 104 drive the four swing frames 3 to swing synchronously.

[0050] One common swing motor 102 in this embodiment drives four swing frames 3 to swing synchronously, the number of swing motors is reduced, the steps of installation and debugging are simplified, and the probability of failure is greatly reduced. At thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com