Blockage clearing device

A blocking remover and clearing technology, applied in the direction of injection device, etc., can solve the problems of incomplete clearing, damage to the spray pipeline, incomplete clearing, etc., to clear the blockage, improve the production efficiency, and reduce the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

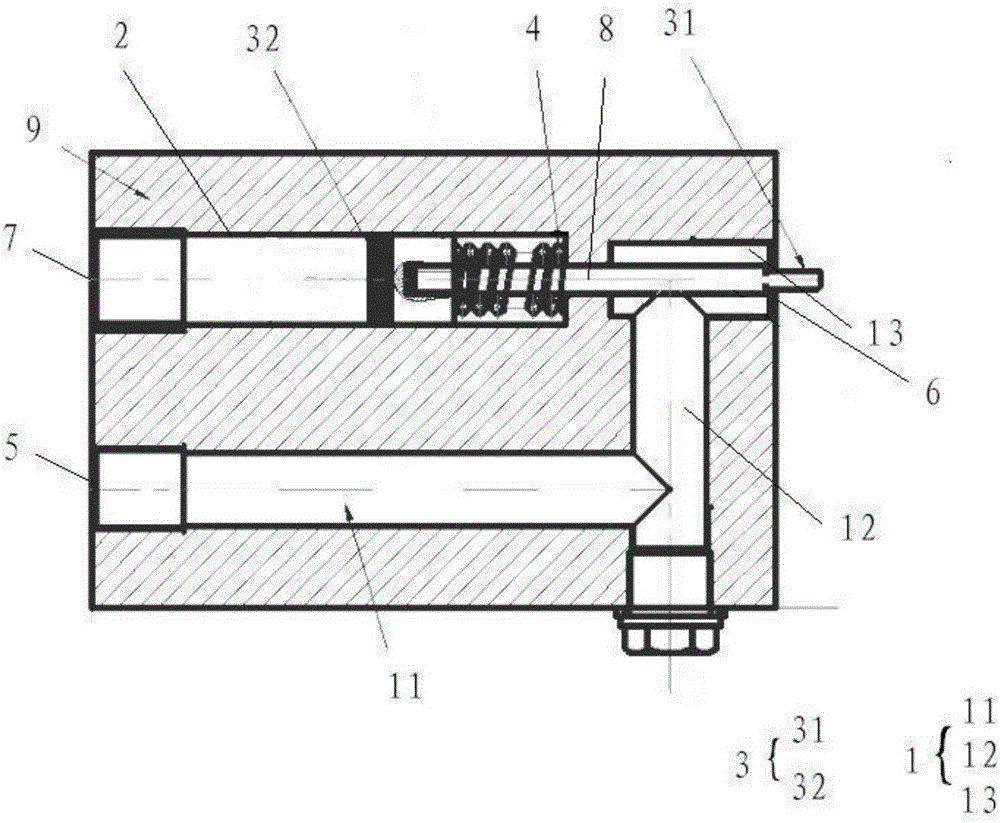

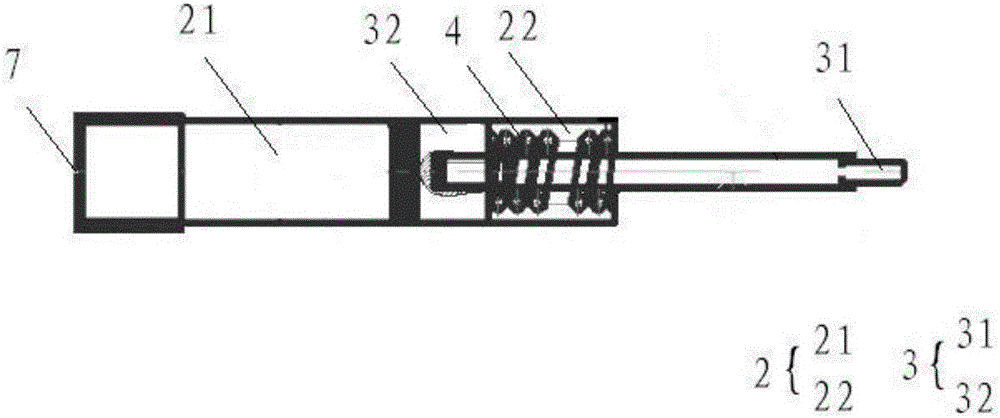

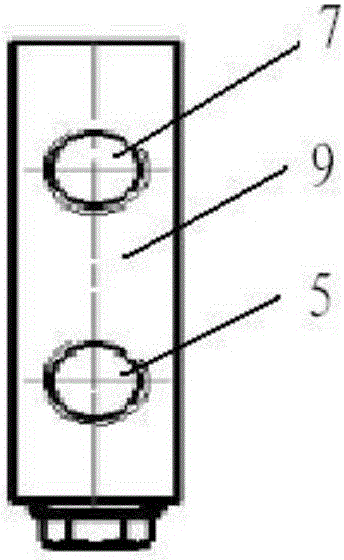

[0046] The technical solutions in the embodiments of the present invention will be clearly and completely described and discussed below in conjunction with the accompanying drawings of the present invention. Obviously, what is described here is only a part of the examples of the present invention, not all examples. Based on the present invention All other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0047] In the prior art, the wet electrostatic precipitator is full of dust, sulfide or heavy metals because the gas to be removed is full of dust, sulfide or heavy metals, so the spray nozzle is easily blocked by the above-mentioned dirt, so that it cannot be sprayed well, and the dust removal effect is poor. The nozzles are all installed inside the wet electrostatic precipitator. When the furnace is not in operation, it is full of smoke and cannot be entered manually. The existin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com