Compact liner coating equipment

A compact, liner technology, applied in the direction of injection devices, etc., can solve the problems of difficult cleaning of residual glue in the equipment, low liner coating efficiency, local thickness out of control, etc., to reduce occupational hazards, simple structure, and slurry loss small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

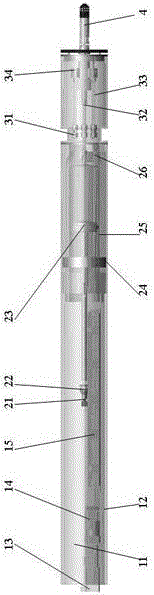

[0016] Below in conjunction with accompanying drawing and example the present invention will be further described:

[0017] Such as figure 1 As shown, a kind of compact liner coating equipment comprises: glue pushing module, glue storage module, spray gun base, rotary spray gun 4, described glue pushing module is composed of cantilever spray bar 11, chassis 12 and is installed on the chassis by The driving mechanism composed of motor 13, reducer 14 and linear module 15 is composed of; the rubber storage module is composed of a rubber storage sleeve 25, a rubber storage cylinder flange block 26, a detachable slider seat 21, a ball head 22, and a piston 23 and the upper and lower fixing blocks 24 of the rubber storage cylinder, the rubber storage module is installed inside the cantilever spray bar 11, the detachable slider seat 21 is connected with the linear module 15, and one end of the piston 23 is inserted into the rubber storage sleeve 25; the spray gun The base is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com