Composite hydrocolloid, hydrocolloid dressing and preparation method of composite hydrocolloid

A technology of hydrocolloids and raw materials, applied in capsule delivery, microcapsules, pharmaceutical formulations, etc., can solve the problems of unsustainable efficacy, single function, and safety to be demonstrated, and achieve the elimination of wound inflammation, long storage time, and rapid healing The effect of scar formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

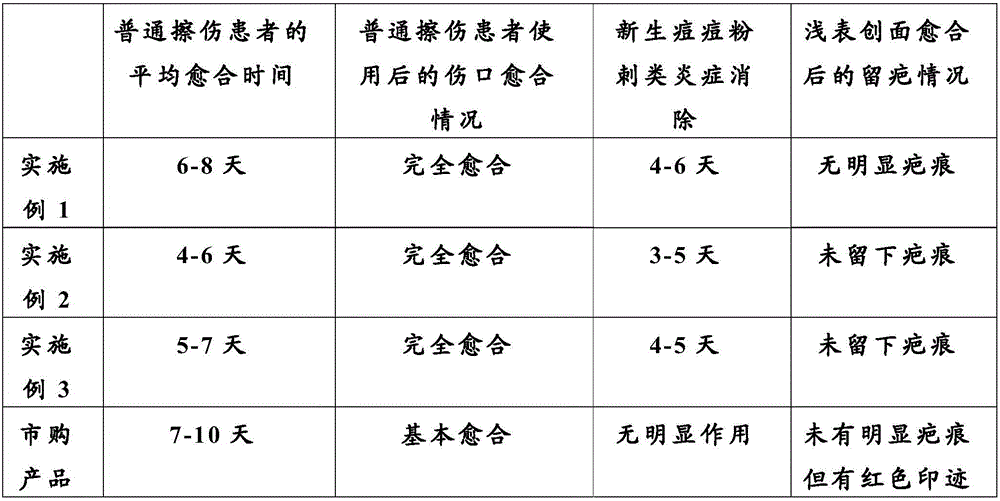

Examples

Embodiment 1

[0033] A hydrocolloid dressing, its preparation method is as follows:

[0034] Step (1), at normal temperature, the tea tree essential oil of 5 weight parts and the microcapsule of 5 weight parts are mixed to make the tea tree essential oil of microcapsule wrapping;

[0035] Step (2), 40 parts by weight of polyisobutylene medical hot-melt adhesive is heated to 130 ° C in a blender to melt, and 5 parts by weight of tourmaline powder with a particle size of 200 mesh and 10 parts by weight of sodium carboxymethyl cellulose Add slowly, and stir at 120°C for 60 minutes under vacuum constant temperature;

[0036] Step (3), slowly adding the microcapsule-wrapped tea tree essential oil prepared in step (1) to the reaction system of step (2), stirring at 100° C. for 5 minutes at a constant temperature in vacuum to make a composite hydrocolloid;

[0037] Step (4), injection molding the composite hydrocolloid on the grid non-woven fabric to form a composite hydrocolloid layer, covering ...

Embodiment 2

[0039] A hydrocolloid dressing, its preparation method is as follows:

[0040] Step (1), at normal temperature, the tea tree essential oil of 20 weight parts and the microcapsule of 20 weight parts are mixed to make the tea tree essential oil of microcapsule wrapping;

[0041] Step (2), 100 parts by weight of polyisobutylene medical hot-melt adhesive is heated to 150 ° C in a blender to melt, and 50 parts by weight of tourmaline powder with a particle size of 300 mesh and 30 parts by weight of sodium carboxymethyl cellulose Add slowly, and stir at 130°C for 90 minutes under vacuum constant temperature;

[0042] Step (3), slowly adding the tea tree essential oil wrapped in microcapsules prepared in step (1) to the reaction system of step (2), stirring at 120° C. for 15 minutes at a constant temperature in vacuum to make a composite hydrocolloid;

[0043] Step (4), injection molding the composite hydrocolloid on the grid non-woven fabric to form a composite hydrocolloid layer, ...

Embodiment 3

[0045] A hydrocolloid dressing, its preparation method is as follows:

[0046] Step (1), at normal temperature, the tea tree essential oil of 10 weight parts and the microcapsule of 10 weight parts are mixed to make the tea tree essential oil of microcapsule wrapping;

[0047] Step (2), heating 70 parts by weight of polyisobutylene medical hot-melt adhesive to 140 ° C in a blender to melt, 30 parts by weight of tourmaline powder with a particle size of 250 mesh and 20 parts by weight of sodium carboxymethyl cellulose Add slowly, and stir at 125°C for 70 minutes under vacuum constant temperature;

[0048] Step (3), slowly adding the tea tree essential oil wrapped in microcapsules prepared in step (1) to the reaction system of step (2), stirring at 110° C. for 10 minutes at a constant temperature in vacuum to make a composite hydrocolloid;

[0049] Step (4), injection molding the composite hydrocolloid on the grid non-woven fabric to form a composite hydrocolloid layer, coverin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com