Discharge door mechanism and solid material box

A kind of technology of discharge door and discharge port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention is described in detail through the following embodiments. However, those skilled in the art should understand that the following embodiments do not limit the protection scope of the present invention, and any improvements and changes made on the basis of the present invention are within the protection scope of the present invention.

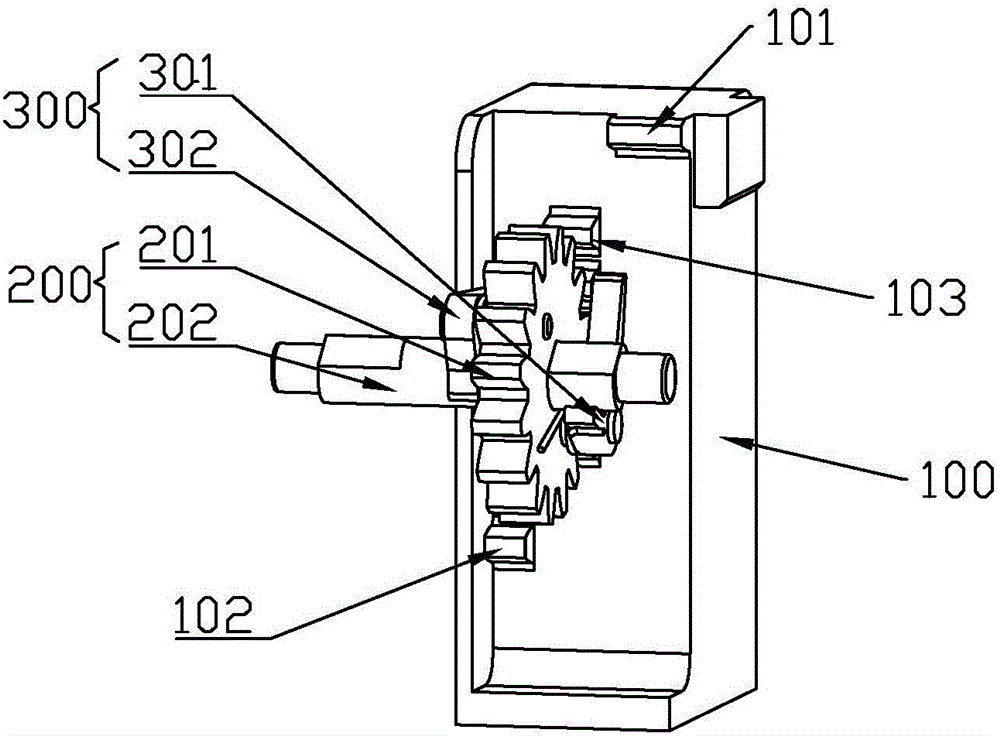

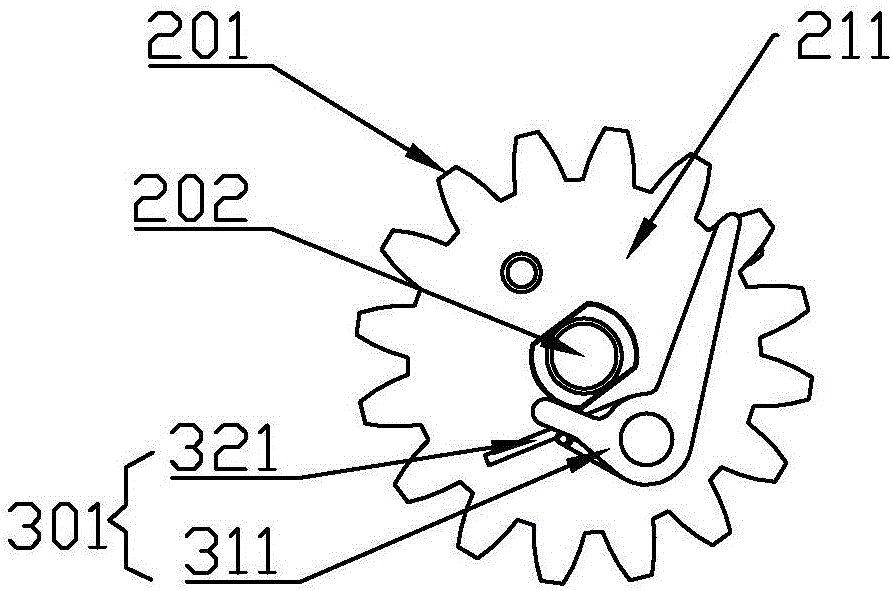

[0053] Refer to attached figure 1 Shown is a schematic structural view of an embodiment of the discharge door mechanism of the present invention. This discharge door mechanism is mainly used to be installed in the discharge device of intelligent discharge, as an on-off device on the conveying channel of the material, so as to meet the accuracy of the conveying amount of the material during conveying, the sealing performance, and the cleanliness of use. needs. The discharge door mechanism includes a driving docking part 200 and a blocking door 100, wherein the blocking door 100 is used to close the discharge opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com