a milk machine

A milk machine and machine body technology, applied in the field of milk machines, can solve the problems of user inconvenience, waste of milk powder, difficulty in controlling the amount of milk powder, etc., and achieve the effects of precise control of water temperature, less moisture and deterioration, and short milk preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

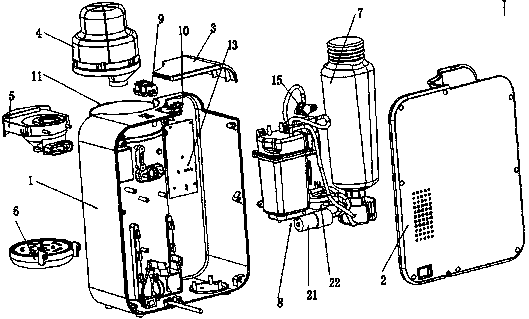

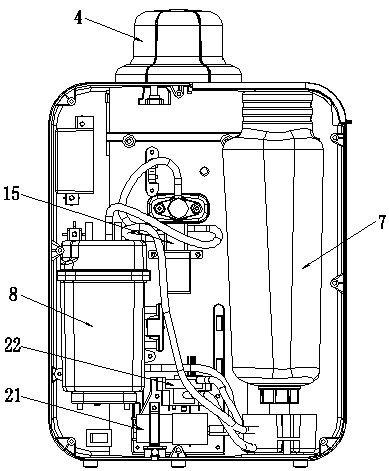

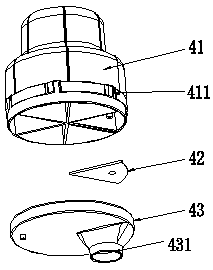

[0024] The structure schematic diagram of a milk making machine in this embodiment is as follows: Figure 1 to Figure 3 As shown, it includes a control unit, a pumping micro switch 10, a flow meter 22, a body 1, a milk powder box 4, a mixer 5, and interconnected heaters 8, pumps 21 and water bottles 7; heaters 8, pumps 21 And the flow meter 22 is electrically connected with the control unit, the flow meter 22 is located between the pump 21 and the water bottle 7 or between the heater 8 and the pump 21, and the flow meter 22 is located between the pump 21 and the water bottle 7 in the present embodiment; 4 and the mixer 5 are installed on the body 1, and the heater 8, pump 21, flow meter 22 and water bottle 7 are installed inside the body 1; the milk powder box 4 includes a lower cover 43 and a milk powder box detachably connected with the lower cover 43 The main body 41, and the milk powder box main body 41 is rotatable relative to the lower cover 43; the lower cover 43 offers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com