Gum base type smoke-free tobacco product and preparation method thereof

A smokeless tobacco, gum-based technology, applied in the direction of tobacco, tobacco processing, application, etc., can solve the problem of high irritation, achieve the effect of long-lasting flavor preservation, reduced volatility, and improvement of sore throat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

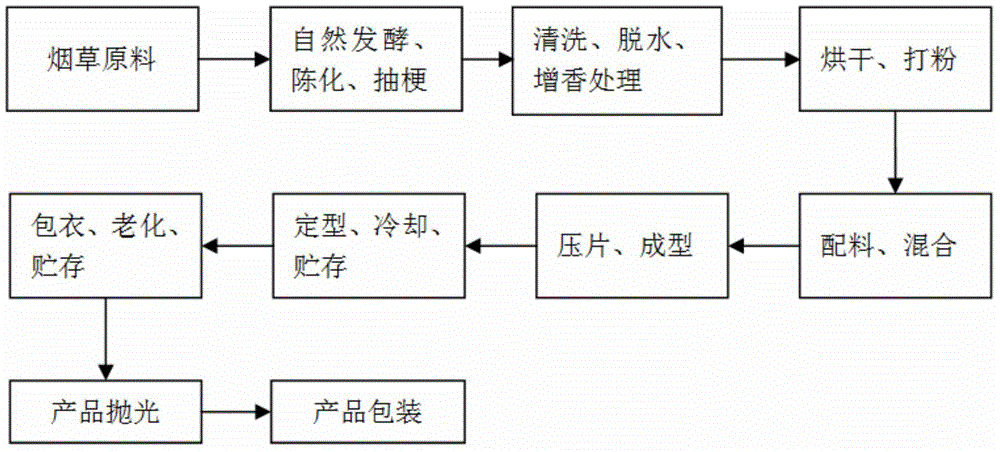

[0074] The present invention also provides a preparation method for the gum-based smokeless tobacco product, which specifically includes the following steps:

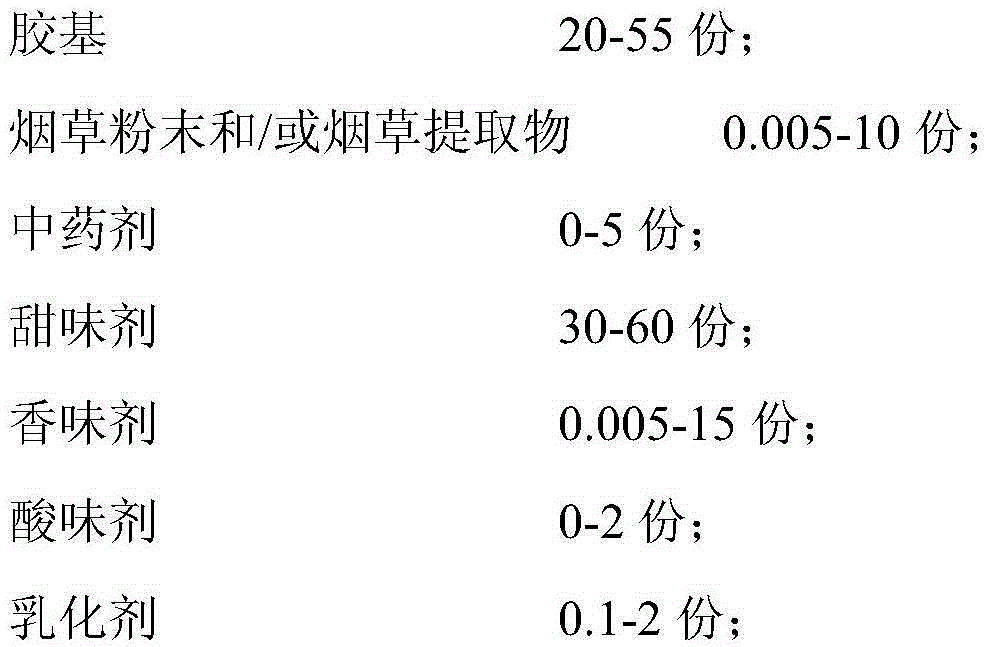

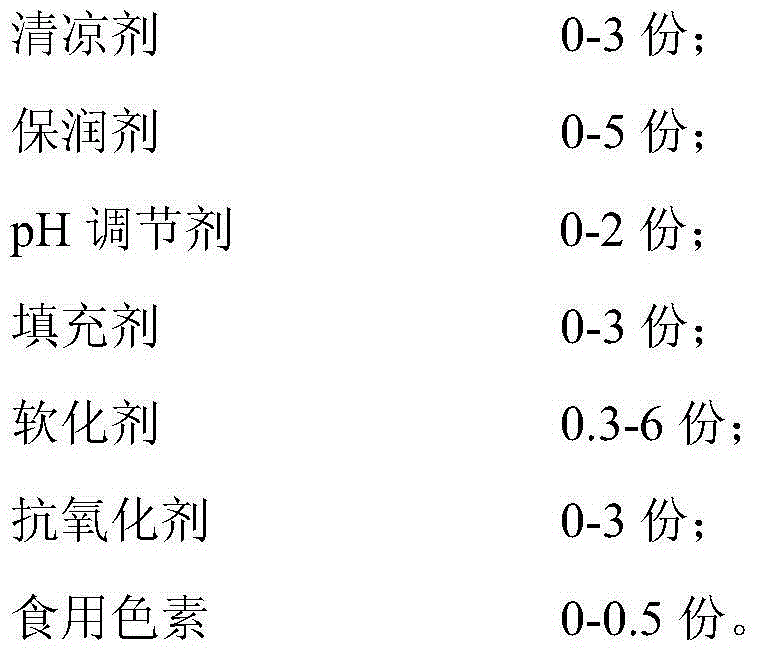

[0075] (1) After the gum base is softened, add tobacco powder and / or tobacco extract, traditional Chinese medicine, sweetener, flavoring agent, sour agent, emulsifier, cooling agent, humectant, pH regulator, filler, Softener, antioxidant, food coloring, etc. When adding some raw materials, you can add appropriate amount of water and stir until the materials are uniform;

[0076] (2) Press the material obtained in step (1) into a sheet with a certain thickness, and then cut and shape it to obtain the gum-based smokeless tobacco product.

[0077] The obtained gum-based smokeless tobacco product is cooled and stored. It is also possible to further coat the shaped gum-based smokeless tobacco product, then polish and wax it after aging and low-temperature storage, and then pack it to complete the product.

[0078] Polishin...

Embodiment 1

[0085] ①The air-dried tobacco (produced in Guizhou, the same below) is naturally fermented and aged for one year, followed by stem extraction, cleaning and dehydration. According to the ratio of licorice: water = 1:10, decoct licorice at 90-100°C for 1 hour, cool down, filter, add honey with a weight ratio of 5% to the filtrate to prepare a spice liquid, and soak the air-dried tobacco with the spice liquid 24-72 hours, carry out flavoring treatment.

[0086] ② After taking out the air-dried tobacco, dry it at 120-140°C until the moisture is less than 3wt%. The dried tobacco material is pulverized and sieved to obtain 100-200 mesh tobacco powder.

[0087] ③Take 10Kg vegetable gum base, soften at 55°C for 1 hour, knead in a kneader for 5 minutes, add 1Kg of 100-150 mesh glucose (sweetener), 4Kg xylitol (sweetener), mix 10 minutes; Then add 4Kg xylitol (sweetener), 1Kg glucose (sweetener), 0.2Kg lecithin (emulsifier), 0.2Kg glycerin (moisturizer), 0.3Kg coffee oil (flavoring ag...

Embodiment 2

[0092] ①The air-dried tobacco is naturally fermented and aged for one year, followed by stem extraction, cleaning and dehydration. Fry at 80-85°C for 1.5 hours according to the ratio of honeysuckle: water = 1:15. After filtering, add corn syrup with a weight ratio of 10% to the filtrate to prepare a spice liquid, and soak air-cured tobacco in the spice liquid for 24 hours. -48 hours, for aromatization.

[0093] ②Take out the air-cured tobacco from the spice liquid, turn it in a cage to remove moisture, and dry it at 60-80°C until the moisture is less than 3wt%. The dried tobacco material is pulverized and sieved to obtain 100-200 mesh tobacco powder. Weigh Chinese medicinal materials according to the formula: 0.2Kg Buza leaves, 0.2Kg jelly grass, 0.2Kg frangipani, 0.14Kg Hangbai chrysanthemum, 0.12Kg Prunella vulgaris, 0.12Kg honeysuckle, 0.04Kg licorice, after drying, crush and sieve to obtain 100 -200 mesh Chinese herbal medicine powder.

[0094] ③ Get 20Kg vegetable gum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com