Winding method for ignition coil

An ignition coil and wire winding technology, applied in transformers, electrical components, induction energy storage devices, etc., can solve the problems of space occupied by walls, troublesome installation of slot windings, complicated production, etc., and achieve simple structure, convenient assembly, and high-voltage insulation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

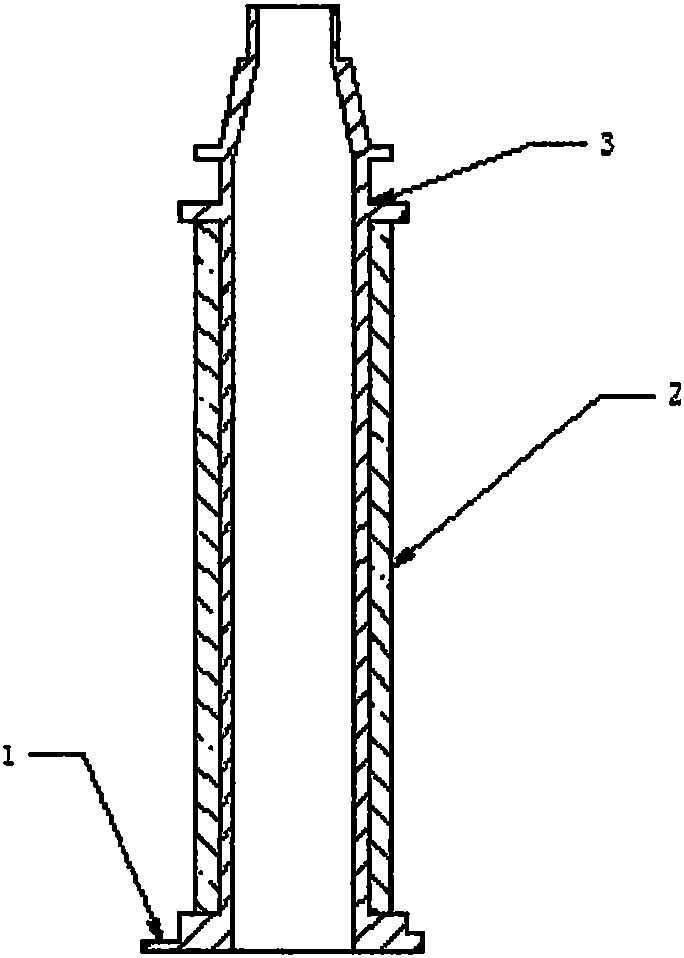

[0012] Embodiment: A pen type ignition coil winding method of the present invention includes a high-voltage skeleton 3 , a metal wire 2 , and a pin 1 . The metal wire 2 is wound on the high-voltage skeleton, and the pin is at the bottom of the skeleton, and is combined with the pen type ignition coil. It is characterized in that: the body is in the shape of a cylinder, and the bottom end of the body is connected with pins. In the above-mentioned high-voltage coil winding method, the high-voltage skeleton must be smooth and clean without any burrs. The winding method of the metal wire is that the first step is to wind forward for a certain distance, and then the second step is to wind backward for a certain distance, which is slightly less than forward winding. Repeat the first and second steps until the winding is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com