Incubation and magnetic separation device applied to chemiluminescence determination

A magnetic separation device and chemiluminescence technology, which is applied in the direction of chemiluminescence/bioluminescence, and analysis by making materials undergo chemical reactions, can solve problems affecting work efficiency, reaction cup rupture, and affecting incubation reactions, etc., to avoid safety Accident problems, prevention of reagent outflow, good effect of magnetic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

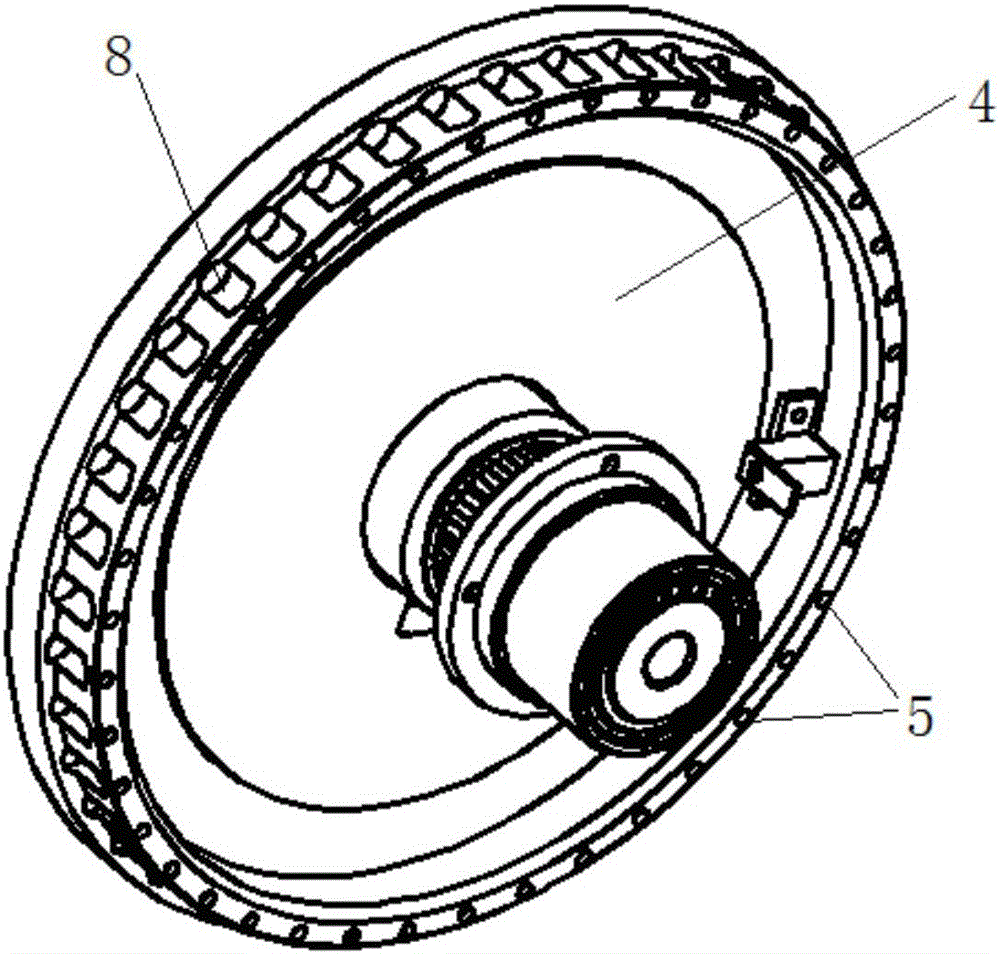

[0042] Such as Figures 1 to 5 As shown, an incubating magnetic separation device applied to chemiluminescent determination, including an incubating device and a magnetic separation device;

[0043] The incubating device includes an incubating device, including an incubating plate 1, a conductive slip ring 2, a turntable motor 3, a heating sheet 4, a temperature sensor 5, and a support 6. The incubating plate 1 is arranged on the support 6, and the incubating plate The back side of 1 is provided with a heating plate 4 and a temperature sensor 5; the conductive slip ring 2 is arranged at the center of the incubating plate, and the wires of the heating plate 4 and the temperature sensor 5 are all wound on the conductive slip ring 2; the turntable motor 3 The axis of rotation of the incubator is connected to the center of the incubating plate 1; a number of cuvette holes 8 are arranged on the round edge of the incubating plate 1;

[0044] Described magnetic separation device com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com