A combined hatch seal

A sealing and combined technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of small permanent deformation and small compression, and achieve the effect of small compression permanent deformation, high elasticity and large compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

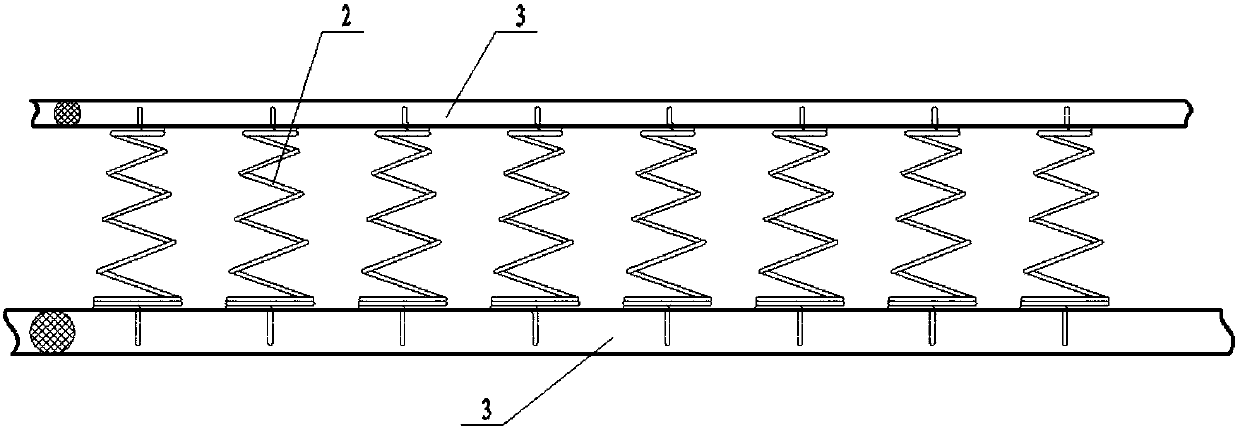

Embodiment 1

[0029] A combined hatch seal, the cross-sectional structure is as attached Figure 4 As shown, the material of the elastic sealing strip is EPDM foam rubber, the hollow cavity is hexagonal, the height of the inner cavity is 27.5mm, the wall thickness of the top of the cavity is 2mm, and the bottom of the inner cavity is a groove of R2.5; The compression spring is a stainless steel conical spring, the diameter of the small end is 5mm, the diameter of the large end is 10mm, the height is 25mm, and the diameter of the spring wire is 0.4mm; the plastic wire is a plastic polyurethane round rod with a diameter of 5mm. The arrangement density of the springs is 67 per meter, evenly distributed, arranged in parallel and fixed in the same plane on one side of the polyurethane round rod, the spring layout structure is as attached Figure 5 shown.

[0030] For the combined hatch seal, the compression direction of the spring is the pressure bearing direction, the maximum compression amoun...

Embodiment 2

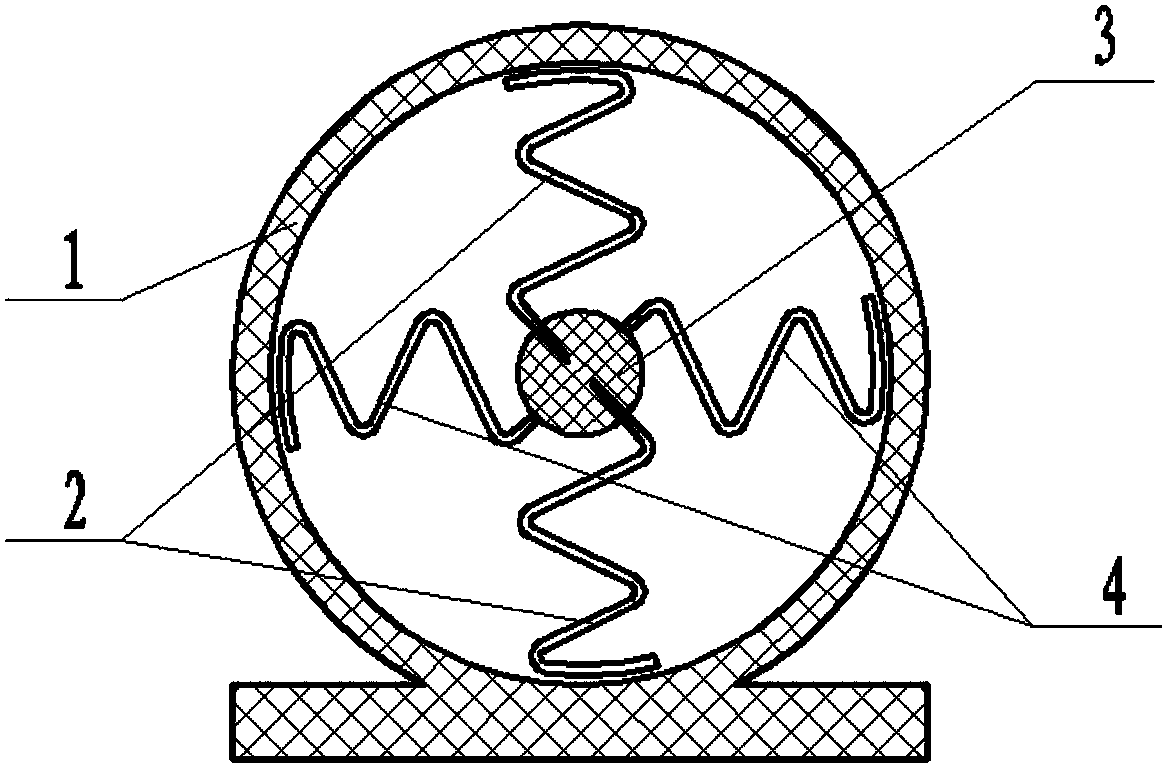

[0032] A combined hatch seal, the cross-sectional structure is as attached Figure 6 As shown, the material of the elastic sealing strip is silicone rubber, the upper part of the sealing strip is a round tube with a diameter of 21 mm, and the lower part is a rubber body with a barbed structure. The height of the rubber body is 10 mm, the width is 4 mm, and the wall thickness of the hollow cavity is 1 mm. There are three chambers, the division direction is parallel to the rubber body with barbed structure at the bottom; the compression spring is a flat bending structure made of stainless steel, the spring height is 7.43mm, and the spring wire diameter is 0.3mm; the plastic wire is 3.8mm in diameter Silicone round stick.

[0033] The arrangement density of springs is 200 per meter per row, which are divided into two rows and arranged evenly and fixed in the same plane on both sides of the plastic wire. The arrangement is as attached Figure 7 As shown, it is installed in the mi...

Embodiment 3

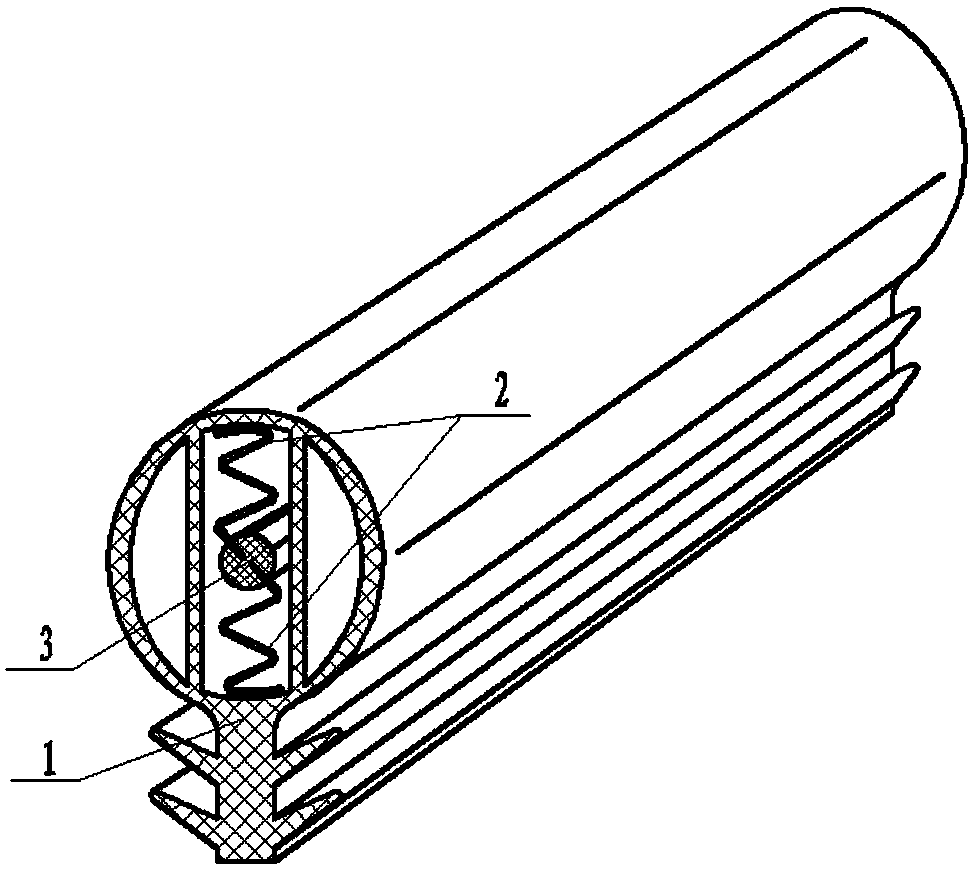

[0036] A combined hatch seal, the cross-sectional structure is as attached figure 2 As shown, the material of the elastic sealing strip is EPDM rubber, the hollow cavity is circular, and there is a rectangular rubber body with a thickness of 3mm and a width of 28mm at the bottom for installation and fixing. The cavity diameter is 25mm, and the wall thickness at the top of the cavity is 1.5mm; the combination form is four rows of springs inserted on the plastic wire; the compression spring is a flat bending structure made of stainless steel, the spring height is 9.7mm, and the spring wire diameter is 0.4mm ; The plastic wire is a polyurethane round rod with a diameter of 5mm. The arrangement density of the springs is 50 per meter, and they are divided into four rows and arranged evenly on the plastic wire, and the radial angle between two adjacent rows is 90°. The compression direction of the spring is perpendicular to the extension direction of the wire rod.

[0037] The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com