Track device for piano production line

A production line and track technology, applied in the track field, can solve problems such as noise generated by mechanical equipment and increase in piano production costs, and achieve good mute effect, good mute effect, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

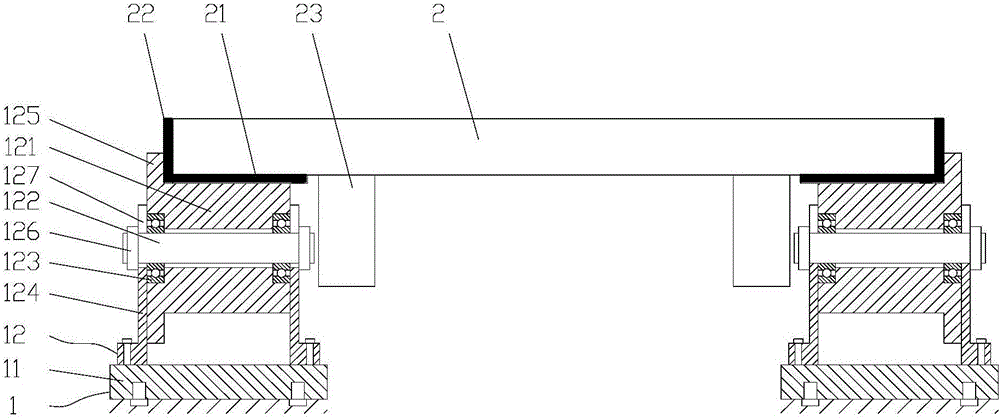

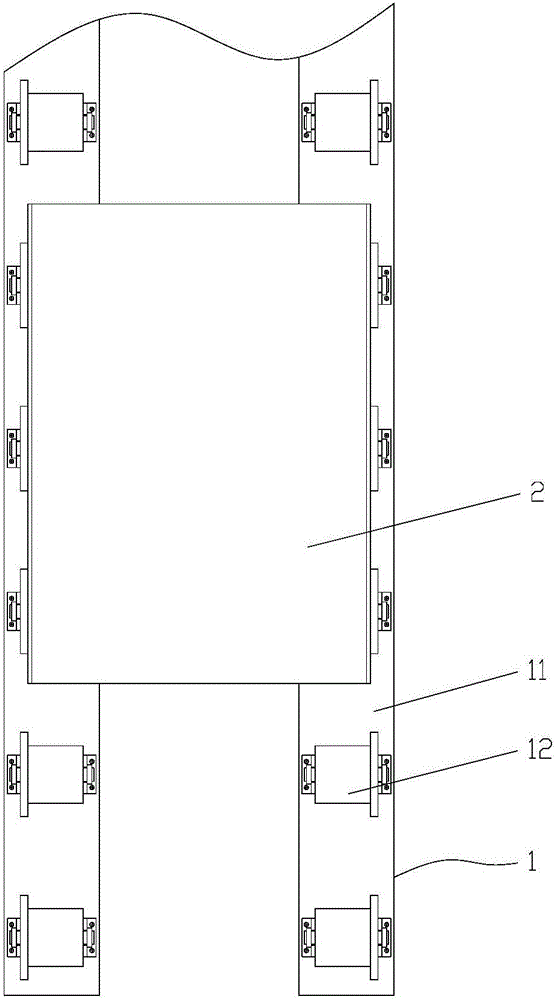

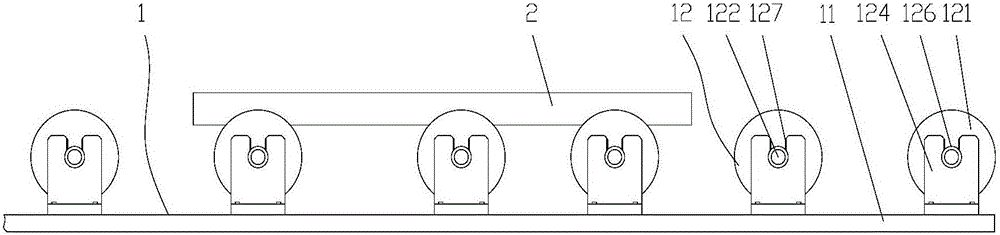

[0018] Such as Figure 1-3 As shown in one of them, the present invention includes a track 1 used to communicate with the piano production line and several bottom plates 2 that are respectively slidably connected to the track 1, and the upper surface of each bottom plate 2 is provided with a fixed structure for fixing the piano (not shown in the figure). ), the track 1 includes two sleepers 11 arranged side by side on the ground, and the tops of the two sleepers 11 are provided with several silent rollers 12 that rotate circumferentially along the vertical plane along the extending direction of the sleepers 11. The rollers 12 all include a roller 121 and a support shaft 122 formed by wear-resistant and quiet materials. A rolling bearing 123 is embedded in both ends of the roller 121. The roller 121 is rotatably connected to the support shaft 122 through the rolling bearing 123. The ends are respectively supported on the supporting seats 124 provided on the sleeper 11. Both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com