An axial flow fan with a vortex breaking structure on the suction surface of the blade and grooves on the top of the blade

A suction surface and blade technology, applied in the field of axial flow fans, can solve problems such as exhaust noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

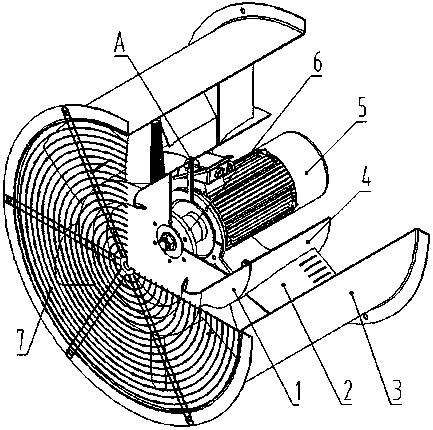

[0022] like figure 1 As shown, the axial flow fan consists of 7 parts, including 1. impeller, 2. guide vane, 3. outer cylinder, 4. inner cylinder, 5. motor, 6. shaft sleeve, 7. net cover; outer cylinder 3, The guide vane 2 and the inner cylinder 4 are fixed together by welding, and the motor 5 is fixed on the web of the inner cylinder 4, wherein the working parameters of the motor 5 are 720r / min, and the power is 4KW; the impeller 1 is fixed on the motor through the sleeve 6 On the 5th axis, the gap between the hub of the impeller 1 and the inner cylinder 4 is 10mm; the net cover 7 is installed on the outer cylinder 3, and has the functions of rectifying and preventing foreign matter from entering.

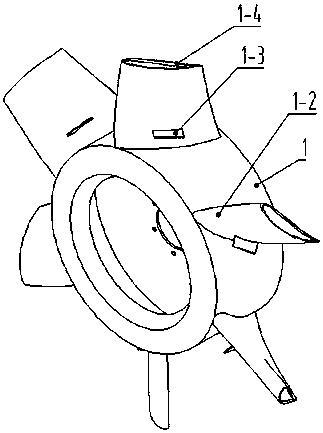

[0023] like figure 1 , 3 As shown, the impeller 1 is driven by the motor 5 to do work for the gas to increase the dynamic pressure and static pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com